Shielded cable connecting structure and shielded cable connecting method

A technology for connecting structures and wires, which is applied in the direction of conductive connection, connection, two-part connection device, etc., can solve the problems of low working efficiency, unstable impedance, waste of man-hours, etc., and achieve the effect of simple structure and preventing the impedance from becoming unstable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, preferred embodiments of the shielded wire connection structure and the shielded wire connection method according to the present invention will be described in detail with reference to the accompanying drawings.

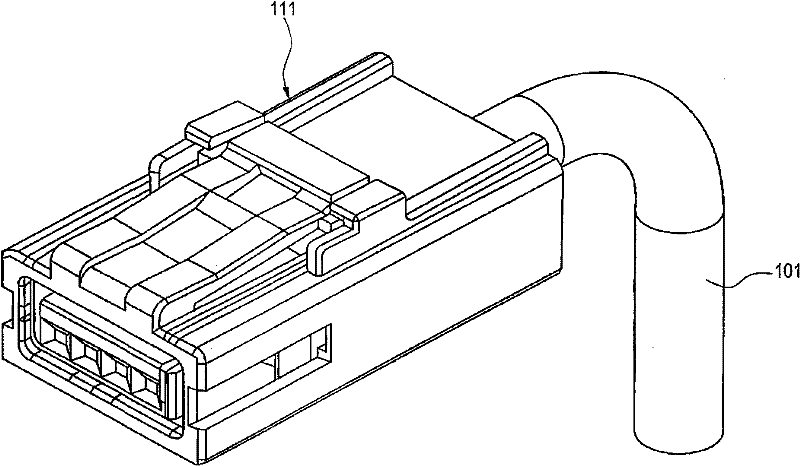

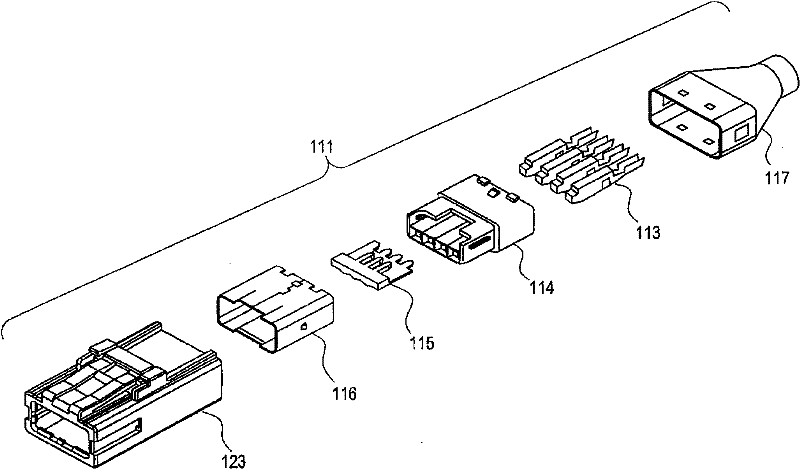

[0054] figure 1 In the shielded wire connection structure involved in the present invention, a Figure 6 A perspective view of an embodiment of the shielded connector 111 of the shielded electric wire 101.

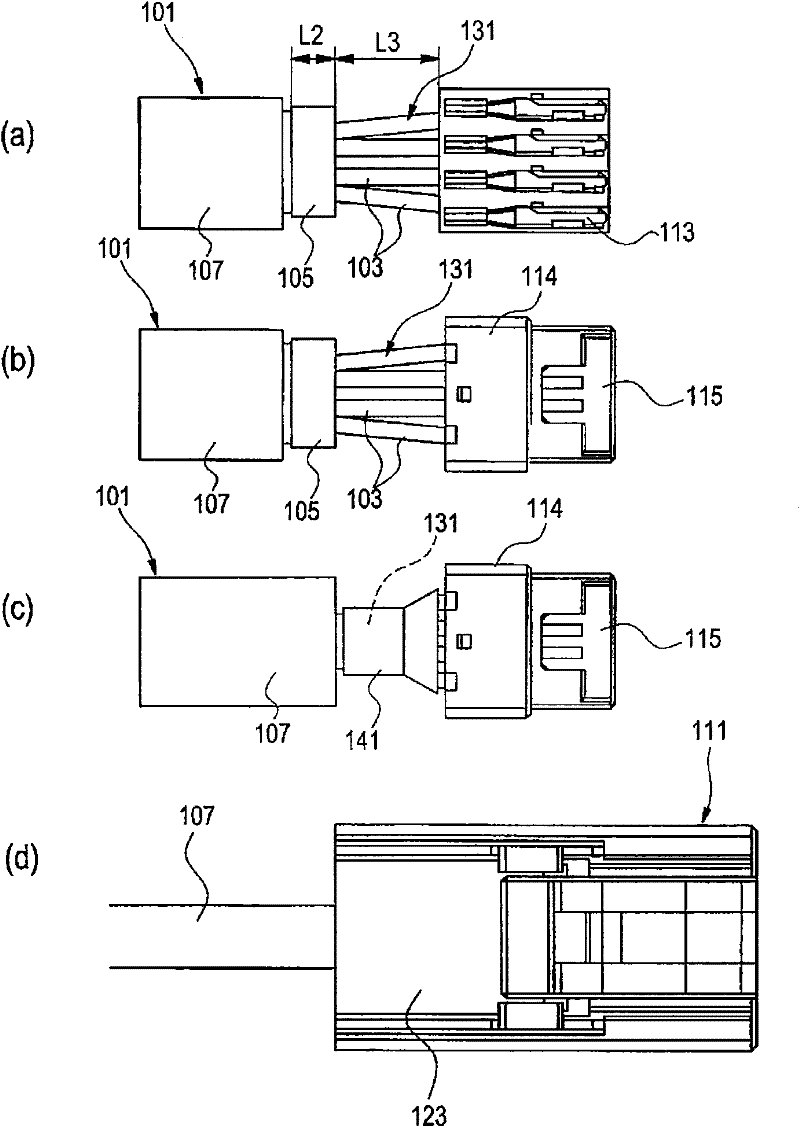

[0055] Such as Figure 6 As shown, the shielded wire 101 includes a plurality of coated wires 103, an electromagnetic shielding layer 105 covering the outer circumference of the plurality of coated electrical wires 103, a braided layer 106 made of conductive metal covering the outer circumference of the electromagnetic shielding layer 105, and a braided layer 106 covering the outer circumference of the electromagnetic shielding layer 105. An insulating sheath 107 around the outer periphery of the braid 106 . The above-mentioned electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com