Double closed zipper automatic head threading machine

A head threading machine and closed tail technology, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of closed tail closing chain, high labor intensity and high cost, so as to improve the yield, reduce production costs, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

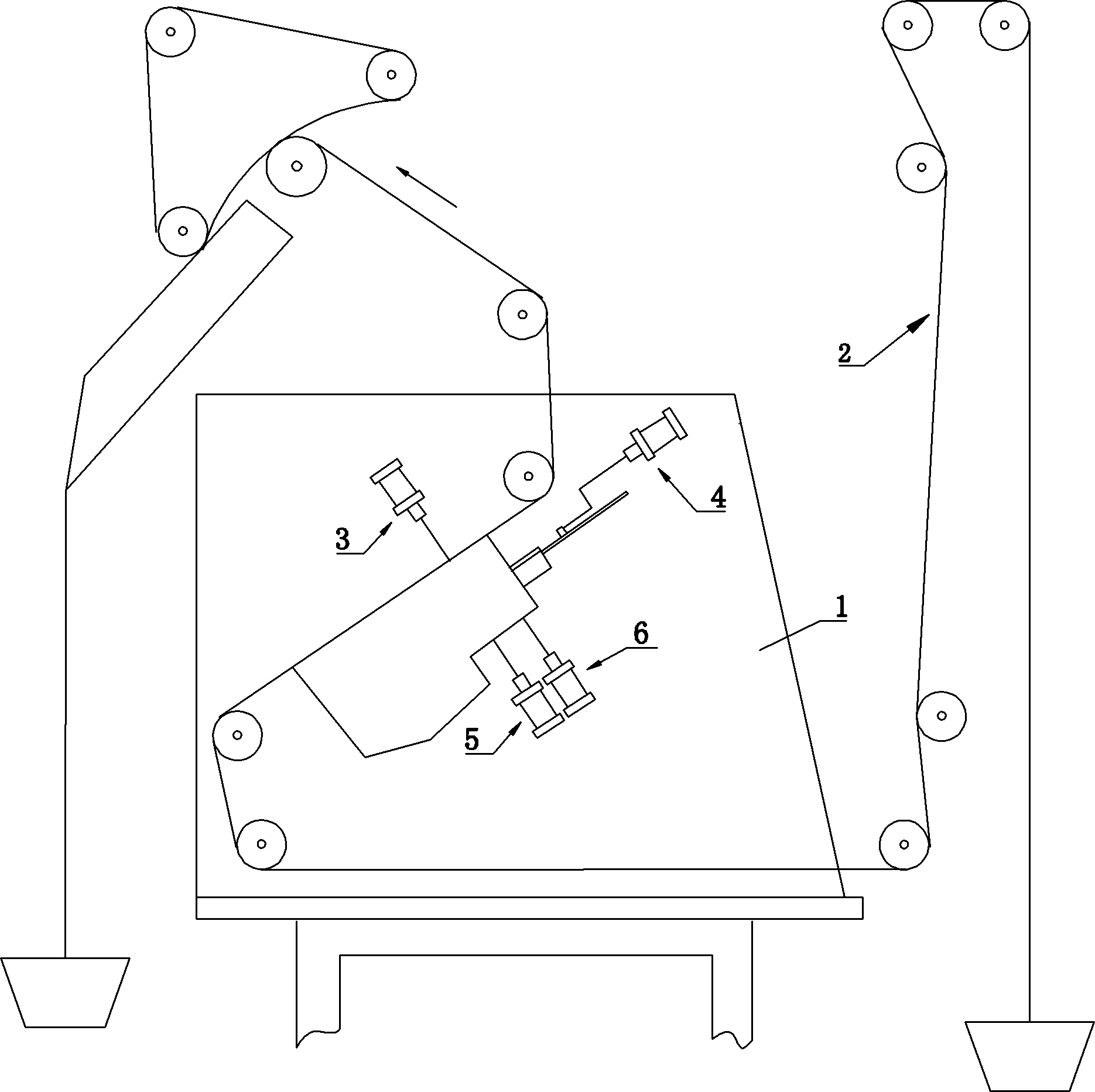

[0021] An automatic head-threading machine for double-closed zippers, refer to figure 1 , comprising: a frame 1; a zipper tape conveying device 2 installed on the frame 1; a supporting knife driven by a first power unit that is movably installed on the frame 1 and used to expand the knife-edge portion of the zipper tape Device 3; the slider conveying device 4 installed on the frame 1 for sending the sliders to the lower mold cavity of the lower mold body 521 one by one; the slider installed on the frame 1 for clamping the sliders A slider clamping device 5 in the opening of the knife-edge portion of the zipper tape, and a chain closure device 6 installed on the frame 1 for closing the zipper tape separated after being worn through the head. It should be noted that the zipper tape conveying device 2 , the knife support device 3 and the slider conveying device 4 are all known structures, and will not be repeated here.

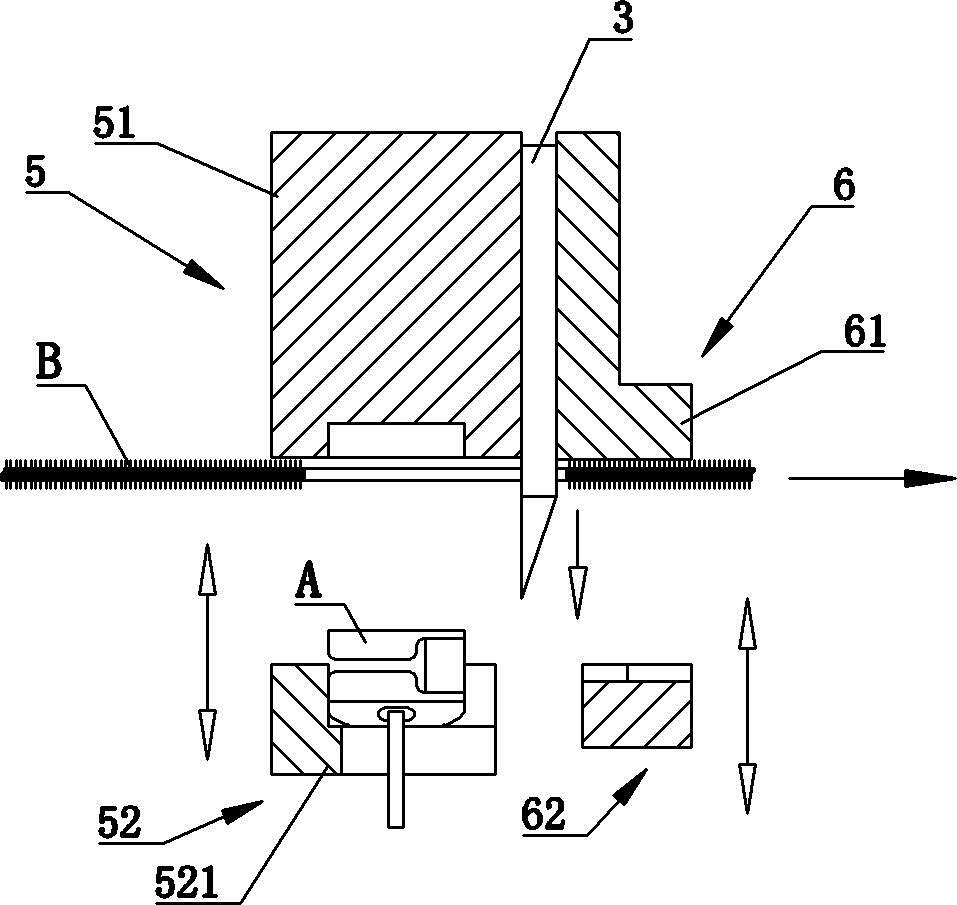

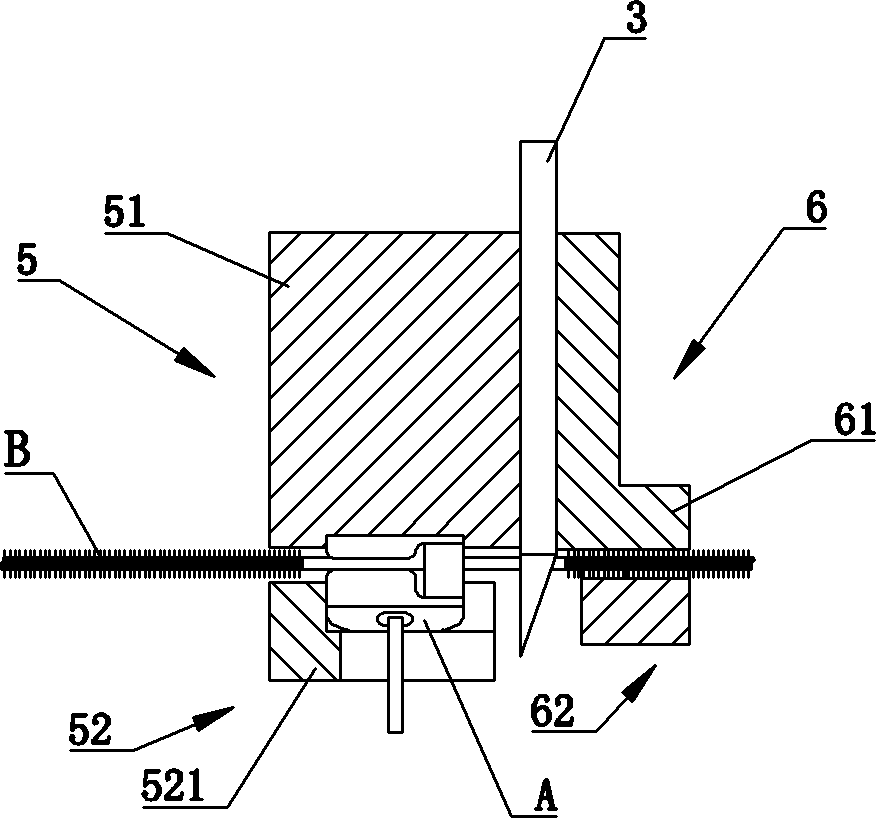

[0022] figure 2 , image 3 and Figure 4 Show the more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com