Calcium magnesium nitrate fertilizer and preparation method thereof

A calcium nitrate magnesium fertilizer, calcium nitrate technology, applied in the direction of nitrate fertilizer, nitrogen fertilizer, fertilization equipment, etc., can solve the problems of continuous automatic production, high production cost, low purity, etc., to promote photosynthesis, improve The effect of simple quality and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

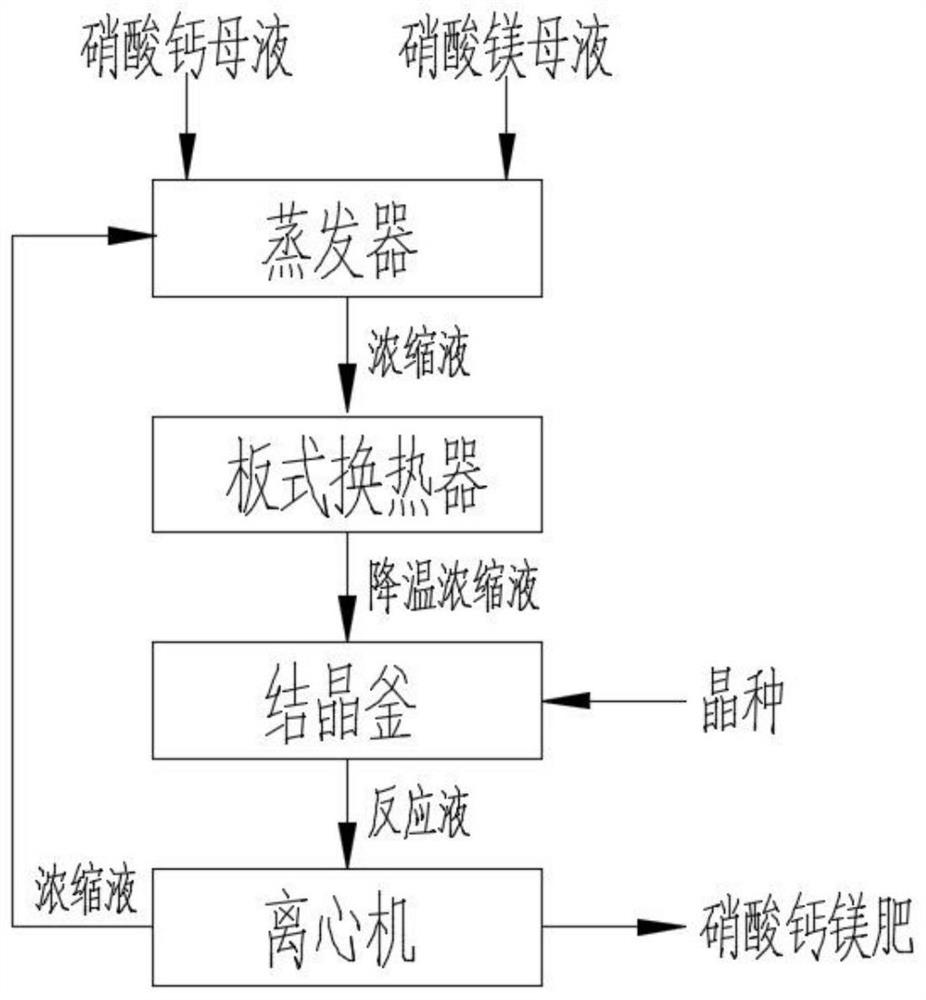

[0032] A preparation method of calcium magnesium nitrate fertilizer, comprising the steps of:

[0033] 1) Solution mixing: Prepare a certain amount of calcium nitrate mother liquor and magnesium nitrate mother liquor respectively, and then mix the prepared calcium nitrate solution and magnesium nitrate solution according to a certain proportion to obtain a mixed solution with a pH value of 6 to 7; The value is not harmful to plants and is conducive to the absorption of plants. The required amount of calcium nitrate mother liquor and magnesium nitrate mother liquor is directly used, without the traditional preparation of calcium nitrate first, and then adding magnesium oxide or magnesium hydroxide to obtain calcium magnesium nitrate solution.

[0034] 2) Evaporation and concentration: the mixed solution obtained in step 1) is evaporated and concentrated under normal pressure or negative pressure until the final temperature is 119-122° C. to obtain a concentrated solution, and t...

Embodiment 1

[0048]A calcium magnesium nitrate fertilizer, wherein: the calcium magnesium nitrate fertilizer includes magnesium element, calcium element and nitrogen element, the content of the magnesium element is 4.52 parts by weight, the content of the calcium element is 15.16 parts by weight, and the nitrogen The content of the element is 12.85 parts by weight.

[0049] Furthermore, the calcium and magnesium nitrate fertilizer is granular, and the particle size is 2mm-4mm oval crystal or hexagonal crystal.

[0050] A preparation method of calcium magnesium nitrate fertilizer, comprising the steps of:

[0051] 1) Solution mixing: Prepare the prepared calcium nitrate mother liquor and magnesium nitrate mother liquor with a mass ratio of 1:1, and then mix the prepared calcium nitrate solution and magnesium nitrate solution in a certain proportion to obtain a pH value of 6-7. liquid;

[0052] 2) Evaporation and concentration: the mixed solution obtained in step 1) was evaporated and conc...

Embodiment 2

[0059] A calcium magnesium nitrate fertilizer, wherein: the calcium magnesium nitrate fertilizer includes magnesium element, calcium element and nitrogen element, the content of the magnesium element is 7.81 parts by weight, the content of the calcium element is 5.6 parts by weight, the nitrogen The content of the element was 10.89 parts by weight.

[0060] Furthermore, the calcium and magnesium nitrate fertilizer is granular, and the particle size is 2mm-4mm oval crystal or hexagonal crystal.

[0061] A preparation method of calcium magnesium nitrate fertilizer, comprising the steps of:

[0062] 1) Solution mixing: Prepare the prepared calcium nitrate mother liquor and magnesium nitrate mother liquor with a mass ratio of 1:2, and then mix the prepared calcium nitrate solution and magnesium nitrate solution in a certain proportion to obtain a pH value of 6-7. liquid;

[0063] 2) Evaporation and concentration: the mixed solution obtained in step 1) was evaporated and concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com