Food packaging equipment for plastic containers

A plastic container and food packaging technology, which is applied in the field of packaging technology and equipment for dry, wet or liquid filling food, can solve the problems of large floor area of the whole line, high labor cost, and many operators, so as to save land occupation area, reduce investment and auxiliary costs, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

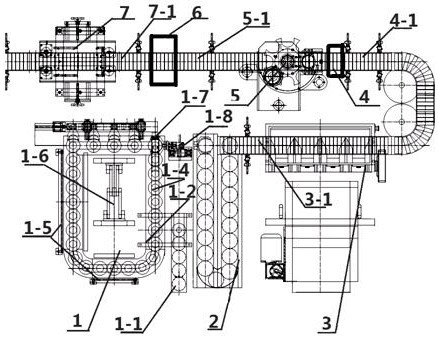

Image

Examples

Embodiment Construction

[0028] The invention discloses a plastic container food packaging process, which is an automatic continuous production process from plastic container molding to food filling. Sent to the food filling process to wait for filling. Since the food can be filled immediately after the plastic container is made online, the process of finished product packaging, finished product storage and finished product transportation in traditional container manufacturing enterprises is saved, as well as the container handling, container storage and container unpacking in traditional food packaging enterprises. , The container is transported to the food packaging production line and many other links, so the risk of container damage in these links is correspondingly eliminated, the product cost is greatly reduced, and the production efficiency is improved. Not only that, due to the change of the process, there is no inventory of plastic containers, which significantly saves the investment cost of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com