Glasses manufacturing method and manufacturing device

A technology for manufacturing devices and spectacle lenses, which is applied in the field of optics and can solve problems such as large product quality fluctuations, low production efficiency, and labor and material resources consumption, and achieve the effects of small product quality fluctuations, labor and material resources saving, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

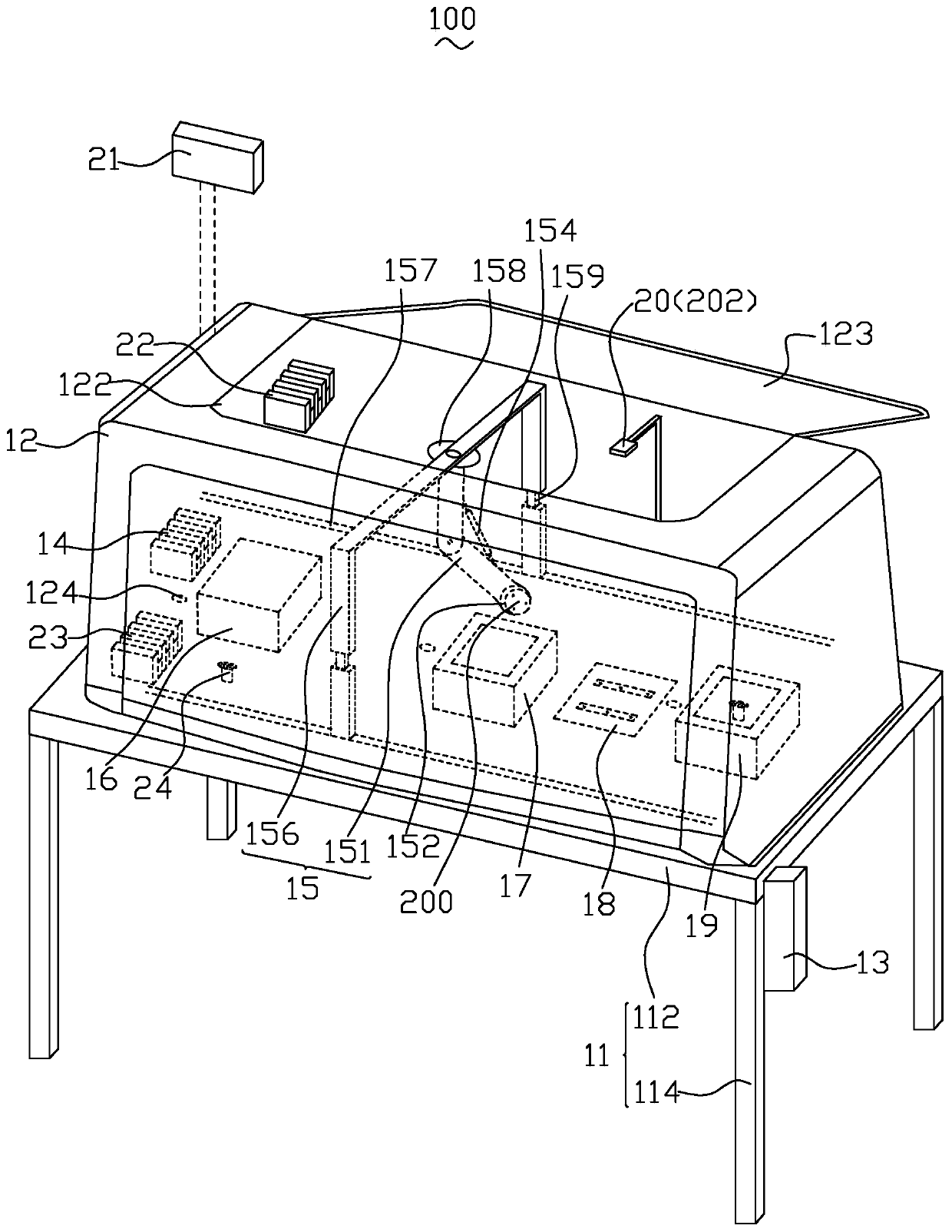

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

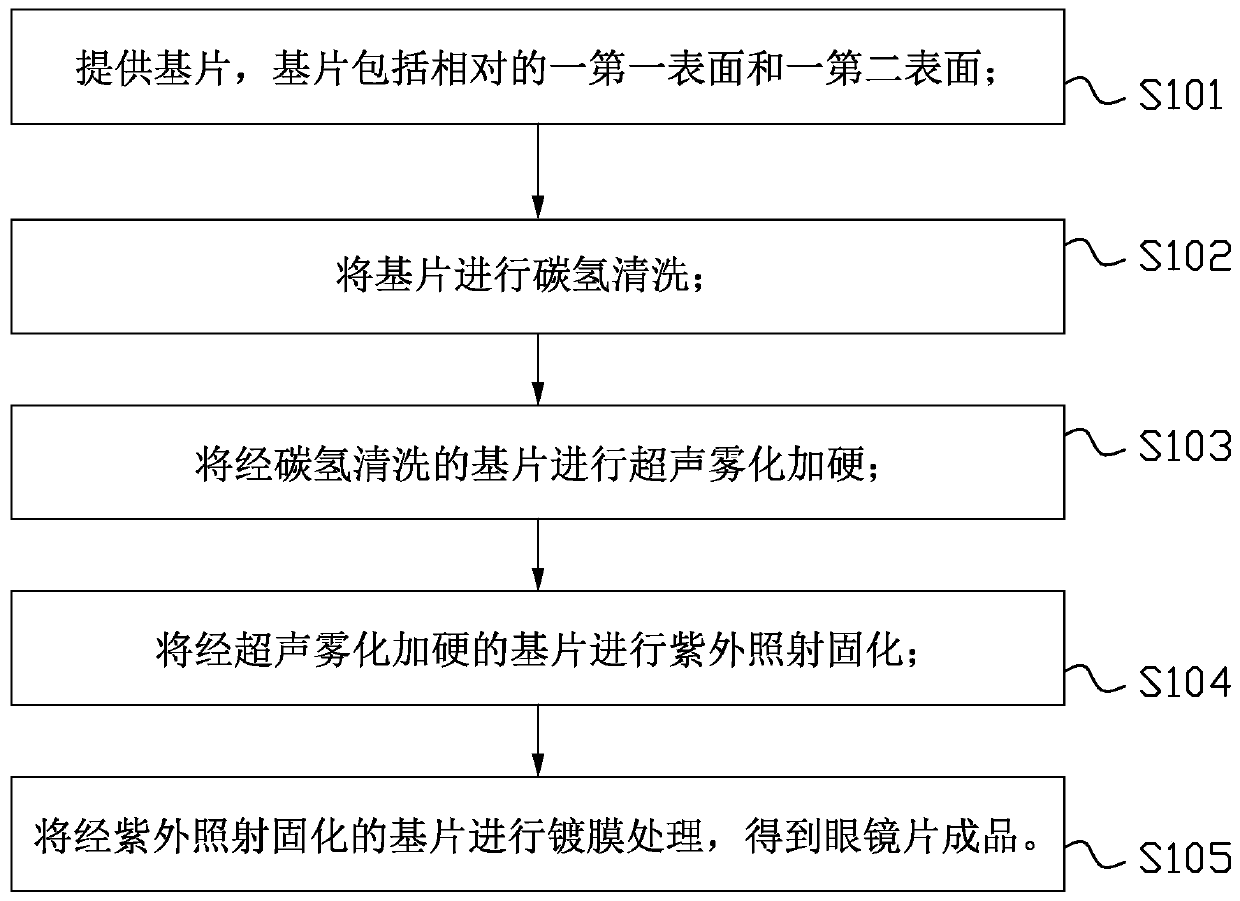

[0018] figure 1 It is a schematic flow chart of the spectacle lens manufacturing method of the embodiment of the present invention, specifically, please refer to figure 1 , spectacle lens manufacturing method of the present invention comprises the steps:

[0019] S101: Provide a substrate, the substrate includes a first surface and a second surface opposite to each other;

[0020] S102: cleaning the substrate with hydrocarbons;

[0021] S103: ultrasonically atomizing and hardening the hydrocarbon-cleaned substrate;

[0022] S104: curing the substrate hardened by ultrasonic atomization with ultraviolet radiation;

[0023] S105: Coating the substrate cured by ultraviolet radiation to obtain a finished spectacle lens.

[0024] In step S101, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com