Lateral coiling equipment for raw material strips of leather mechanical blade

A technology of mechanical blades and raw materials, which is applied in the field of lateral rounding equipment for raw materials of leather mechanical blades, can solve the problems of low production efficiency, consumption of molds, high product scrap rate, etc., and achieve the effect of good roundness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

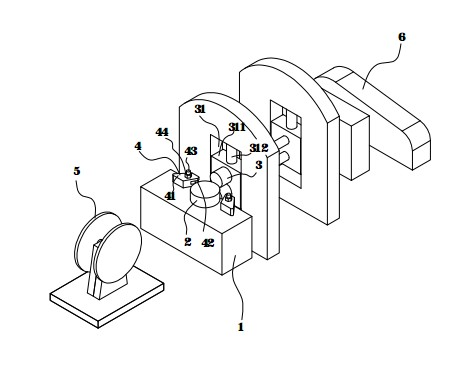

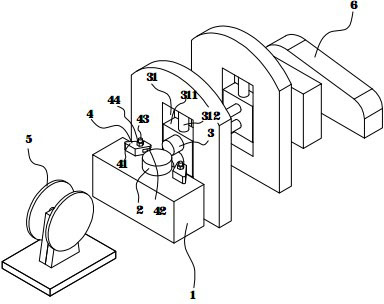

[0016] Such as figure 1 As shown in the figure, a leather machine blade raw material strip side disc rounding device includes a workbench 1 and a material disc 5, and the axis of the material disc 5 is vertically parallel to the horizontal plane. The workbench 1 is provided with a core wheel 2 which can rotate around its own axis, and a pair of rolling wheels 3 are arranged on one side of the workbench 1 . The axes of the pair of rolling wheels 3 are parallel to each other and perpendicular to the axis of the core wheel 2 . Also guide device 4 is housed on the workbench 1, guide device 4 comprises guide block 41, guide wheel 42 is housed on the guide block 41, also adjusting bolt 43 is housed on the guide block 41, is screwed with adjusting nut 44 on the adjusting bolt 43. An adjusting mechanism 31 for adjusting the distance between the pair of rolling wheels 3 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com