Brush wire for PP (polypropylene) road sweeping brush and preparation method of brush wire

A technology of brushing and sweeping the road, applied in the field of daily necessities, can solve the problems of difficult to control the roundness of PP brushed wire, poor roundness and straightness, etc., to achieve good straightness, good roundness, and improved durability. abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Specifically, on the one hand, an embodiment of the present invention provides a method for preparing a brush filament for a PP road sweeping brush, comprising the following steps:

[0033] (1) Mix 80%-98% PP granules, 0-5% toner or color masterbatch, and 2%-15% additives evenly, melt them, extrude them, and then solidify and freeze them to obtain raw silk; The silk is a raw silk with a hollow structure; the percentage is by weight;

[0034] (2) The raw silk is drawn for the first time, then heated for the second time, then shaped for the first time, finally shaped for the third time, and then shaped for the second time to obtain a PP road sweeping brush Brush filaments: the brush filaments for the PP road sweeping brush are hollow brush filaments.

[0035] In step (1),

[0036] The auxiliary agent is a toughening agent. By adding a toughening agent and controlling the dosage to be 2% to 15%, the toughness of the brush filaments can be well increased, and the breakin...

Embodiment 1

[0050] A preparation method for brush filaments for PP road sweeping brush, comprising the steps of:

[0051] (1) 80% PP particles, 5% color masterbatch, and 15% toughening agent are mixed uniformly and then melted, extruded, and then solidified and frozen to obtain a raw silk; the raw silk is a raw silk with a hollow structure; The percentages mentioned are percentages by weight;

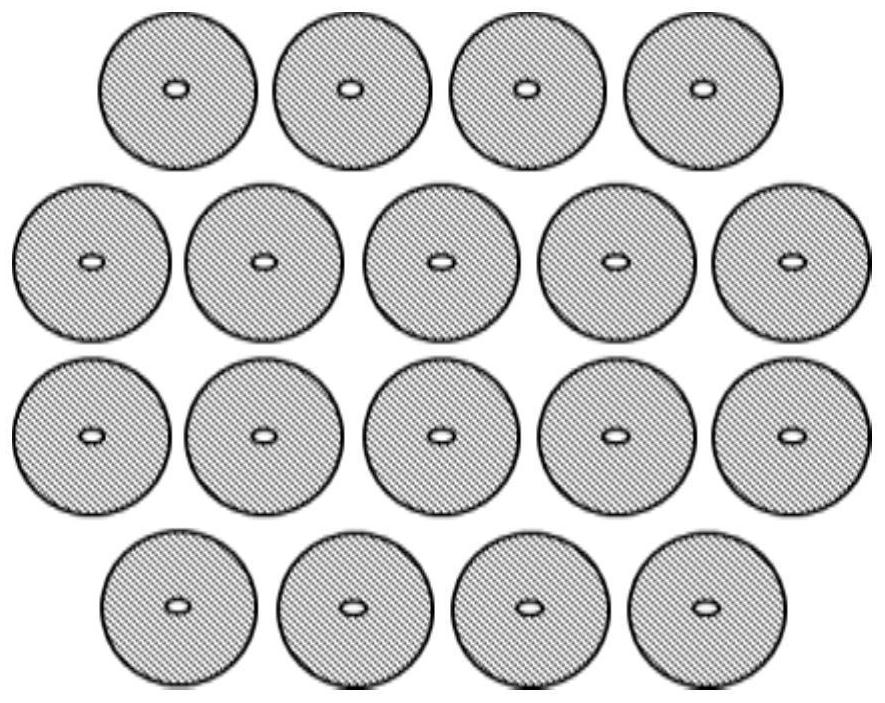

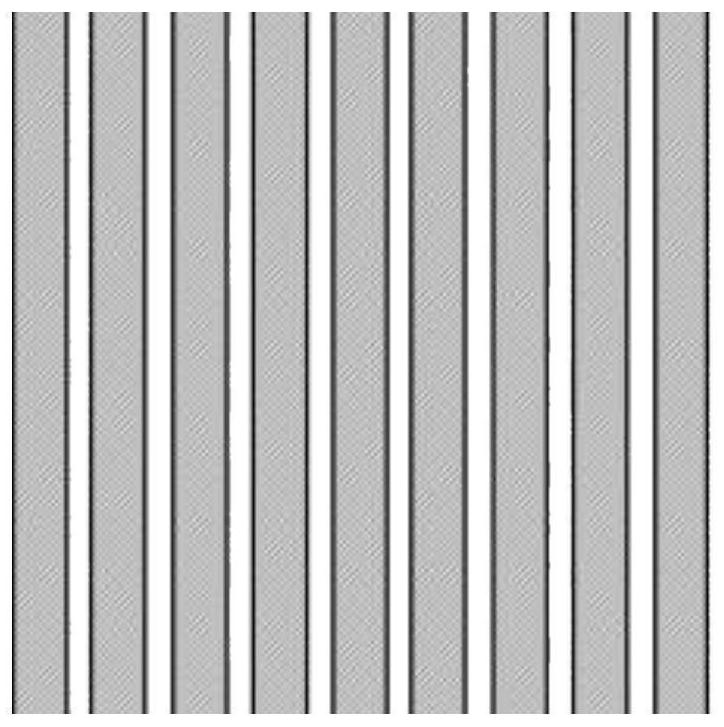

[0052] (2) The raw silk is drawn for the first time, then heated for the second time, then shaped for the first time, finally shaped for the third time, and then shaped for the second time to obtain a PP road sweeping brush Brush filaments: the brush filaments for the PP road sweeping brush are hollow brush filaments. Its cross-sectional structure is as figure 1 As shown, the longitudinal surface structure is as figure 2 shown. From figure 1 It can be seen that the brush filaments for the PP sweeping brush are hollow filaments; figure 2 It can be seen that the brush filaments of the PP road...

Embodiment 2

[0067] A preparation method for brush filaments for PP road sweeping brush, comprising the steps of:

[0068] (1) Mix 98% PP granules and 2% toughening agent evenly, melt, extrude, and then solidify and freeze to obtain the original silk; the original silk is an original silk with a hollow structure; the percentage is by weight ;

[0069] (2) The raw silk is drawn for the first time, then heated for the second time, then shaped for the first time, finally shaped for the third time, and then shaped for the second time to obtain a PP road sweeping brush Brush filaments: the brush filaments for the PP road sweeping brush are hollow brush filaments.

[0070] In step (1),

[0071] The melting and the extrusion were carried out in an extruder at a temperature of 230°C.

[0072] The spinning die of the extruder is a hollow spinning die; the cavity size of the hollow structure is adjusted by the size of the airflow passing into the hollow spinning die.

[0073] The coagulation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com