Explosive block packaging production process

A production process and explosive technology, which is applied in the field of explosive block packaging production process, can solve the problems of poor bonding performance, slow curing speed, high paper damage rate, etc., to improve toughness and moisture resistance, prevent water vapor from intruding, and improve bonding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

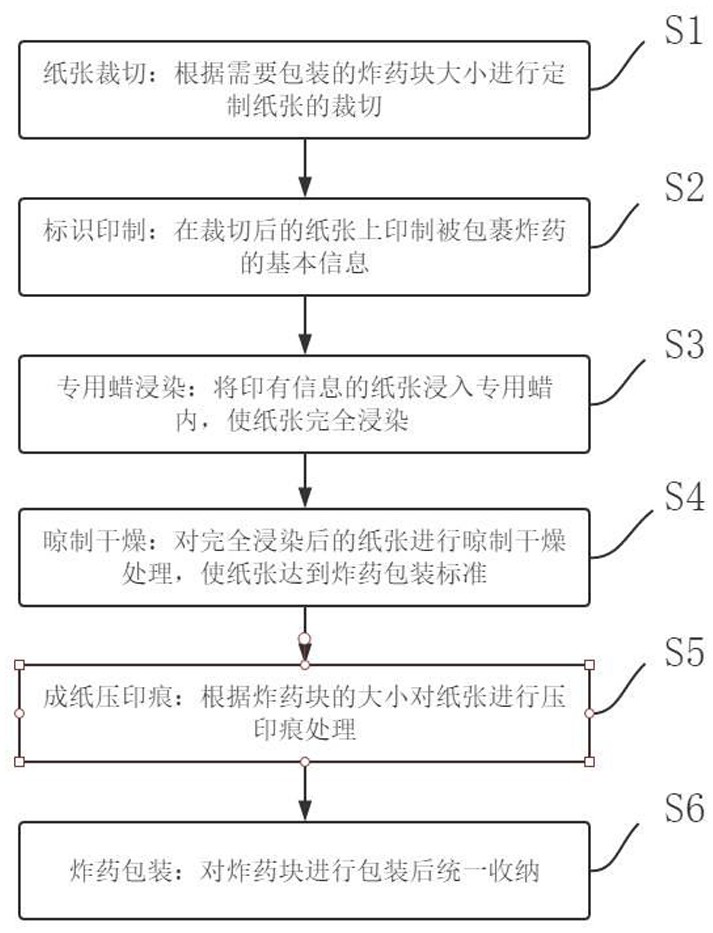

[0023] see figure 1 , the present invention provides a technical solution: a packaging production process for explosive blocks, comprising the following steps:

[0024] Step 1. Paper cutting: Cut the customized paper according to the size of the explosive block to be packed.

[0025] Step 2, mark printing: print the basic information of the wrapped explosive on the cut paper.

[0026] Step 3. Dip dyeing with special wax: Dip the paper with information printed on it into the special wax to make the paper completely dipped.

[0027] Step 4, air drying: carry out air drying treatment on the fully impregnated paper, so that the paper reaches the explosive packaging standard.

[0028] Step 5: Making paper embossment: according to the size of the explosive block, the paper is embossed.

[0029] Step 6. Explosive packaging: pack the explosive blocks and store them in a unified manner.

[0030] Specifically, the paper used in step 1 is special paper for wrapping explosives, the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com