Floating positioning device

A floating positioning and limit pin technology, used in the equipment field of the machinery industry, can solve the problems of difficult part positioning and ejecting functions, small effective space, etc., and achieve the effect of preventing dust and increasing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

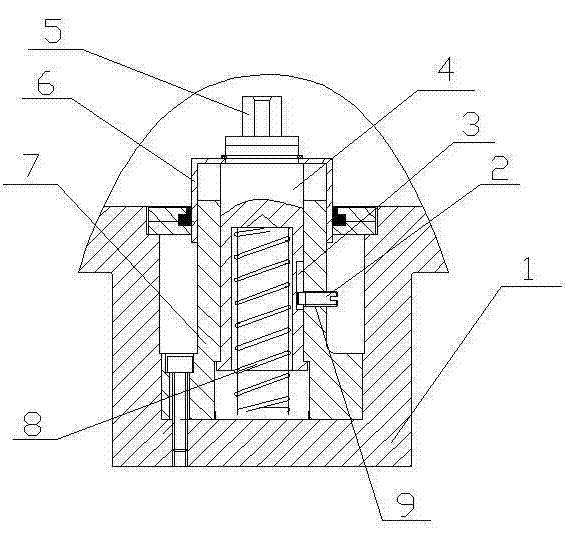

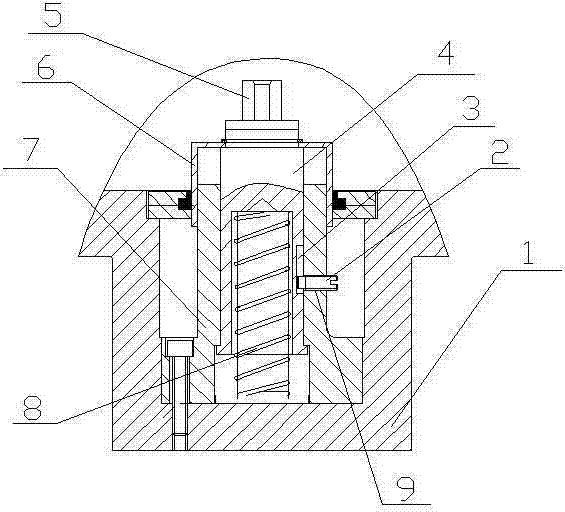

[0010] like figure 1 Said floating positioning device comprises a mounting base plate 1, said mounting base plate 1 is fixedly connected with a circlip 7 for a shaft, and the axial part of the circlip 7 for a shaft is provided with a through hole with a step, and a through hole is provided in the through hole Screw 4, the head of the screw 4 is provided with a positioning pin 5, the bottom of the screw 4 is provided with a blind hole, and a spring 8 is arranged between the installation base plate 1 and the blind hole; There is a protective cover 6; the screw 4 is provided with a limit pin groove 3, and the shaft circlip 7 is provided with a pin hole 9, and the limit pin 2 is installed in the pin hole 9, and one end protrudes from the limit pin in slot 3.

[0011] When the part needs to be positioned, the pin hole of the part is aligned with the positioning pin 5, and the part is fixed with a clamp; when the part needs to be taken out, the clamp is released, the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com