Propeller blades with anti-icing coating

A technology for propellers and blades, applied in the direction of propellers, deicing devices, layered products, etc., can solve the problem of heater elements preventing the operation of the entire element, improve reliability and maintainability, save initial purchase and ongoing maintenance costs , the effect of reducing the radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

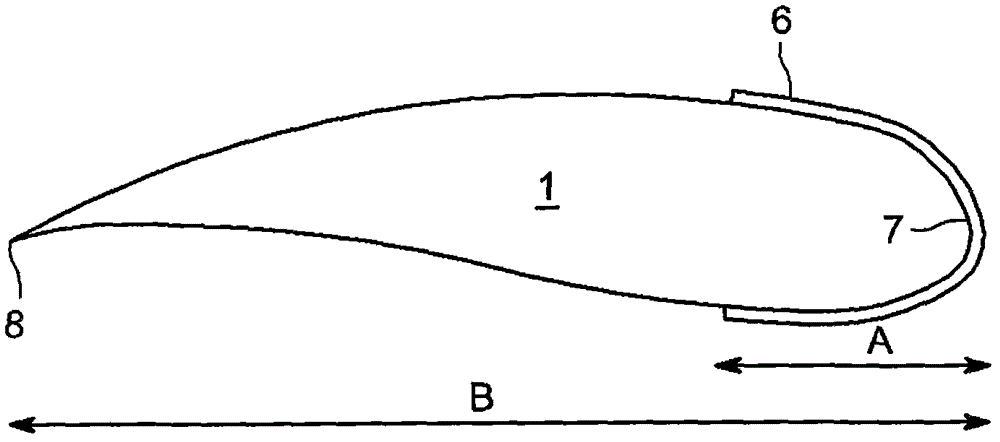

[0016] figure 1 The layer arrangement of the coating 6 applied to the propeller blade 1 is shown. The first adhesive layer 2 is arranged directly adjacent to the blade surface 1 . The polymer layer 3 is arranged on the adhesive layer 2 and is thus firmly fixed to the blade surface. The polymer layer 3 may comprise one or more rubber materials, such as neoprene. In addition, the polymer layer 3 may have a thickness in the range of, for example, 0.5 mm to 1.0 mm. On the neoprene layer 3 an adhesive coating 4 is arranged to provide a suitable surface for bonding a layer 5 of anti-icing material to the coating. The bond coat 4 may have a thickness of about 1 micron. The layer 5 of anti-icing material may have a thickness of about 3mm. The polymer layer 3 may be coloured, whereby wear of the layer of anti-icing material 5 and the coating 4 exposes the polymer layer to provide an indication of wear of the layer of anti-icing material 5 .

[0017] figure 2 The coating 6 appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com