High-shielding reflection film and manufacturing process thereof

A manufacturing process and technology of reflective film, applied in the direction of layered products, cellulose plastic material layered products, polarizing elements, etc., can solve the problems of no privacy, reducing the brightness of direct sunlight, and difficult to identify the scene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

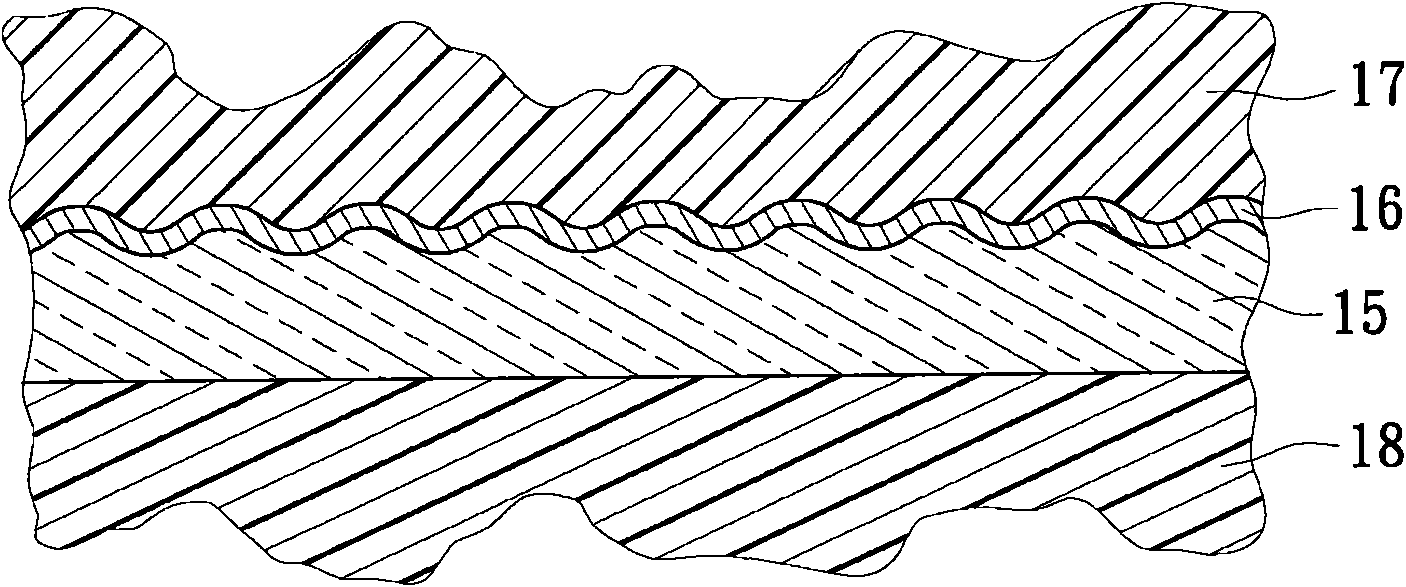

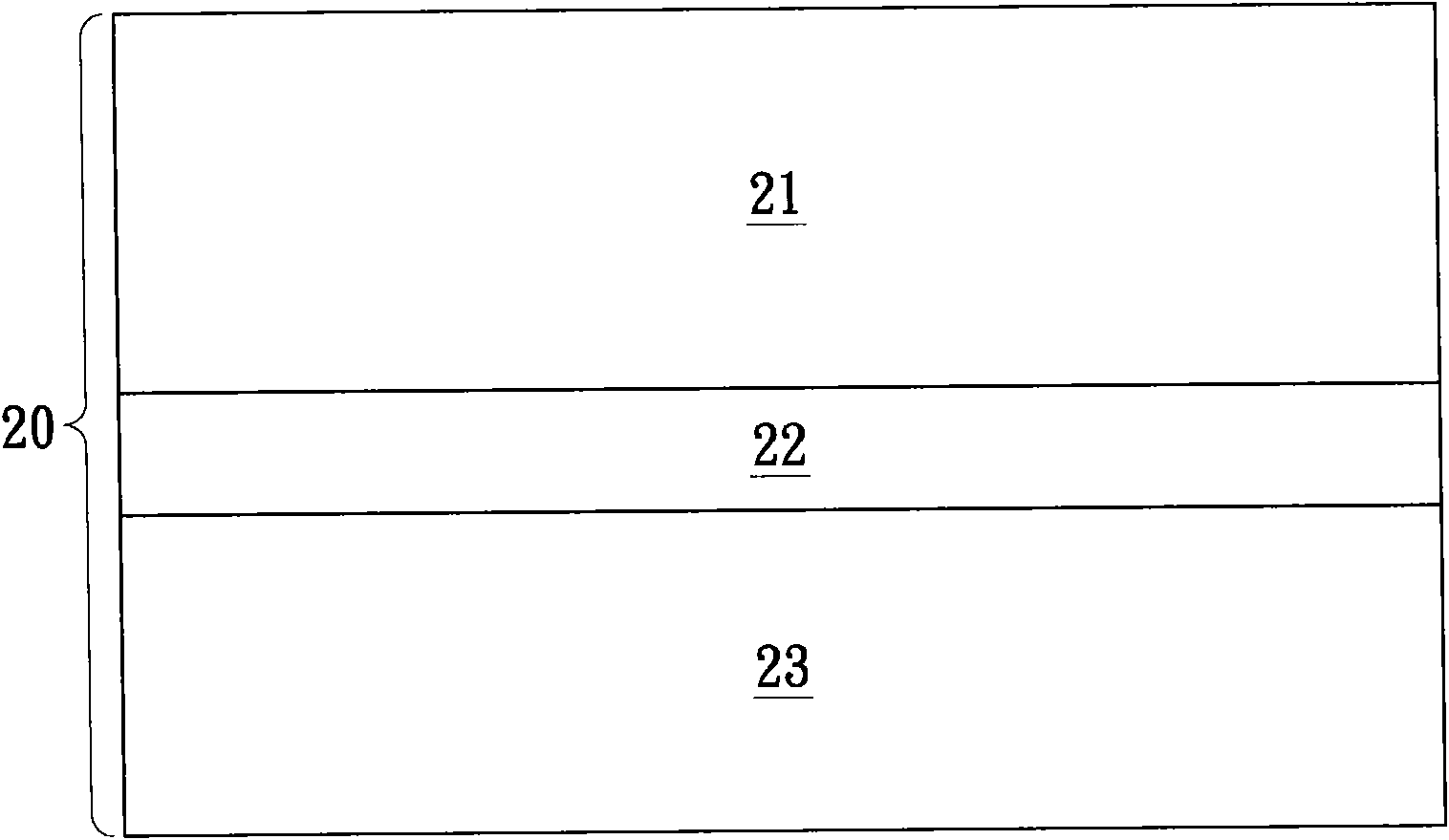

[0025] According to the embodiment of the high shading reflective film proposed by the present invention, please refer to figure 2 Schematic of the embodiment shown. The main structure of the high-shading reflective film 20 includes an optical reflective film 21 and a polarizer 23 , and the upper and lower layers are combined through a bonding layer 22 . One of the embodiments is characterized in that the optical reflection film 21 is formed by repeated stacking of at least two or more different materials, and at least one of the materials has a different refractive index on the axis of different light incident directions, so the optical reflection film 21 has optical anisotropy.

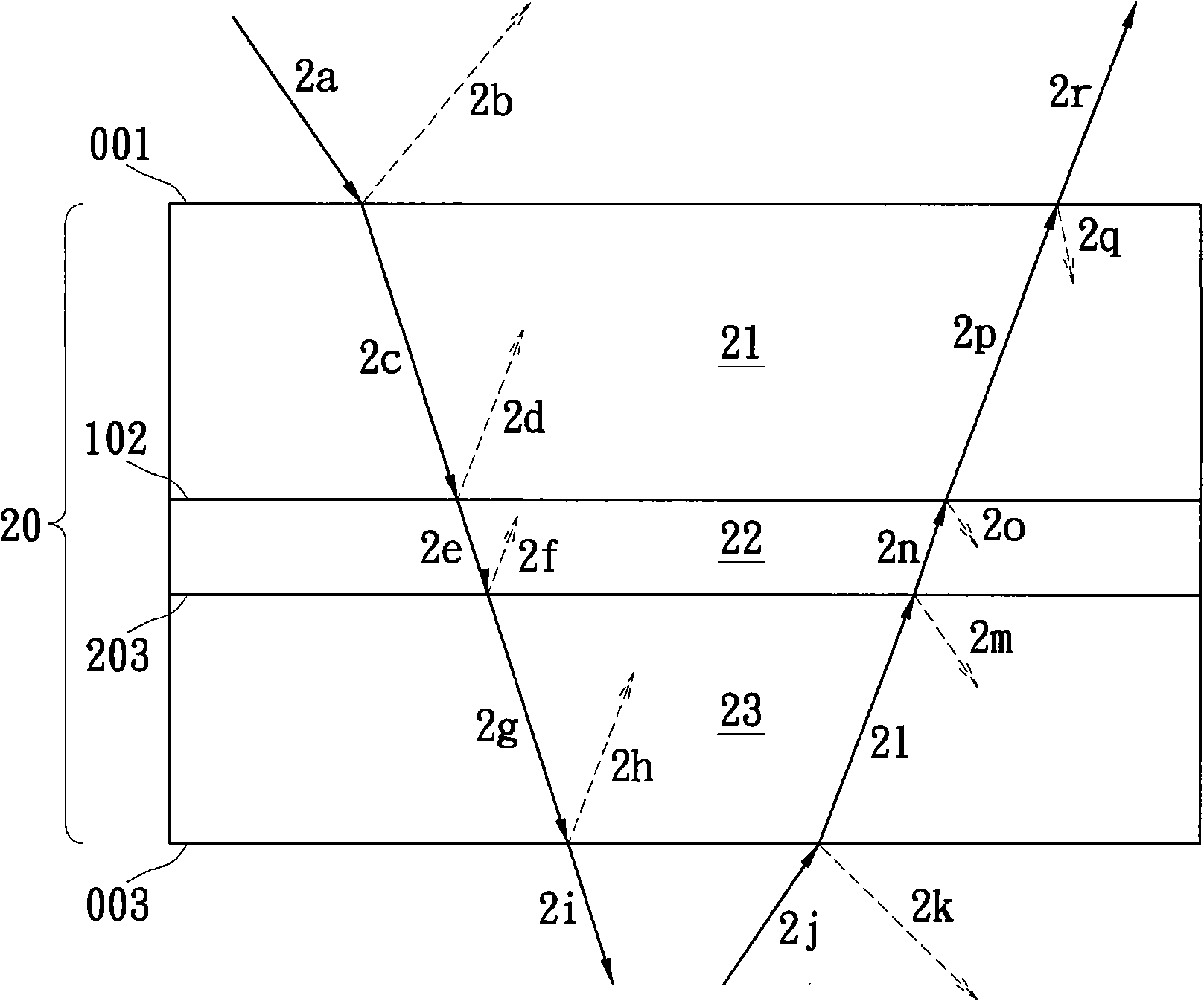

[0026] Each layer structure in the high-shading reflective film 20 can deflect incident light, and produce a high-shading effect through the design of the optical path. Please refer to image 3 According to the schematic diagram of the light path formed by the above-mentioned high-shading reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com