Horizontal battery production system

A production system and horizontal battery technology, applied in the field of automation systems, can solve problems such as low efficiency of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

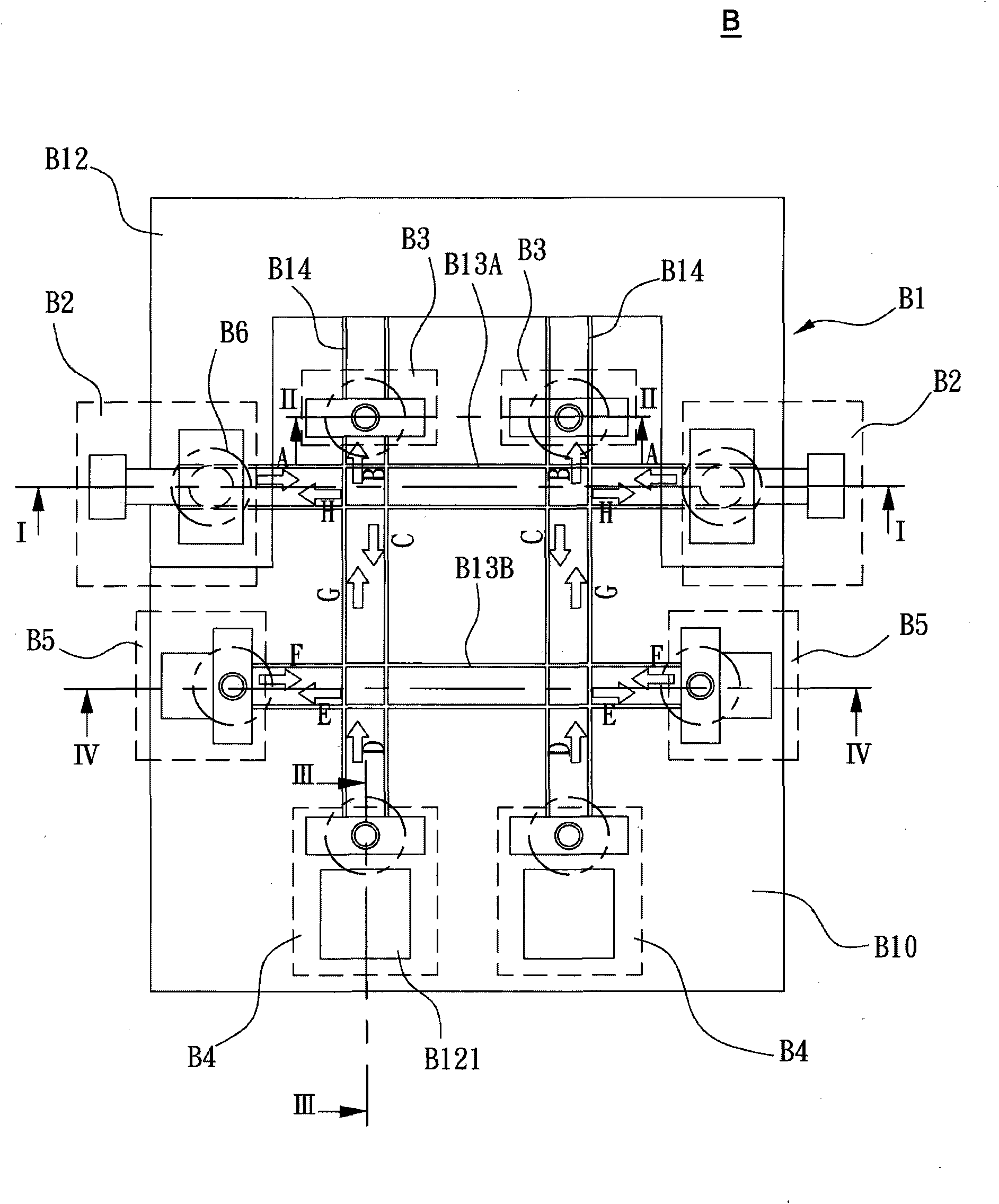

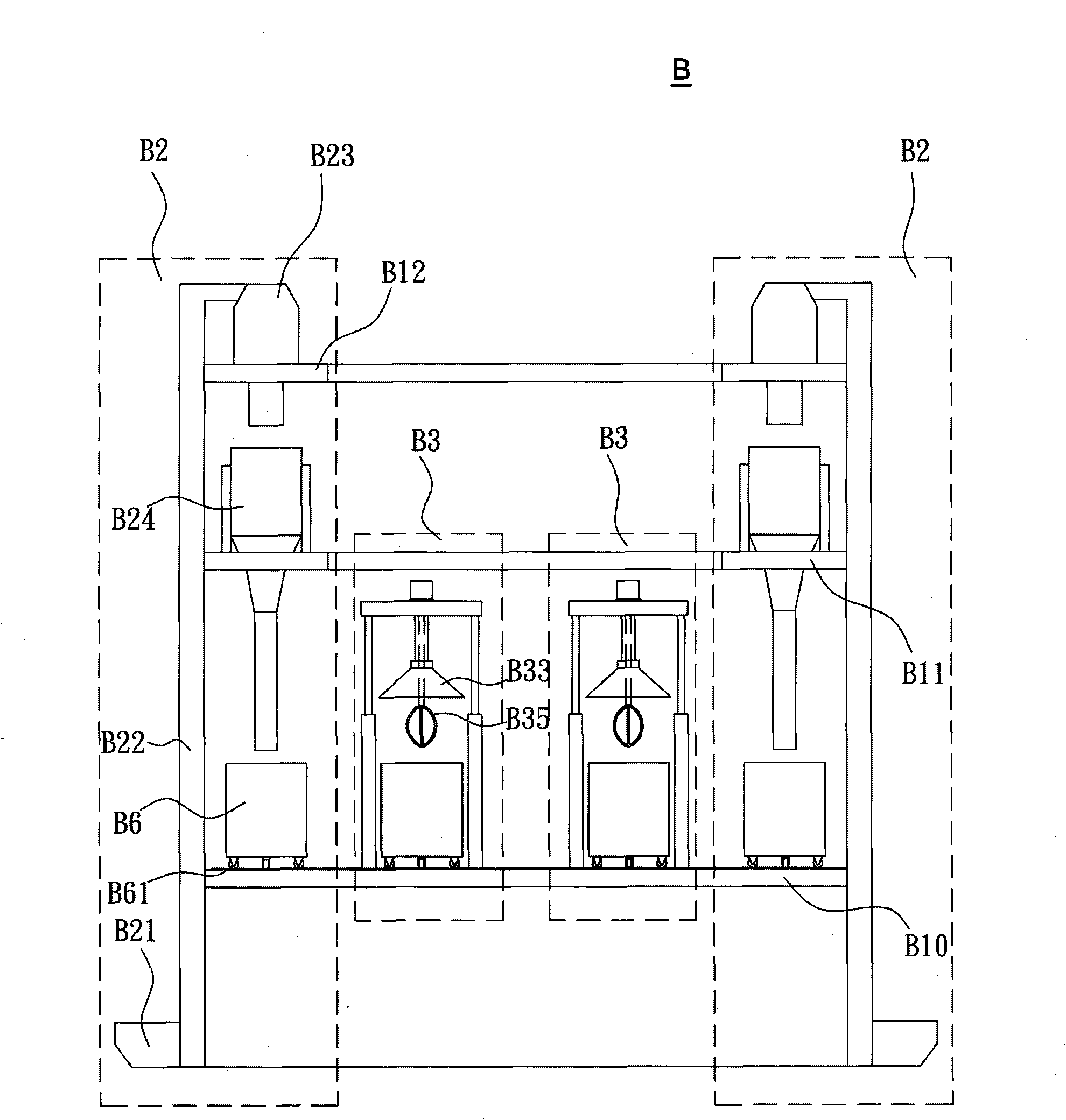

[0051] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

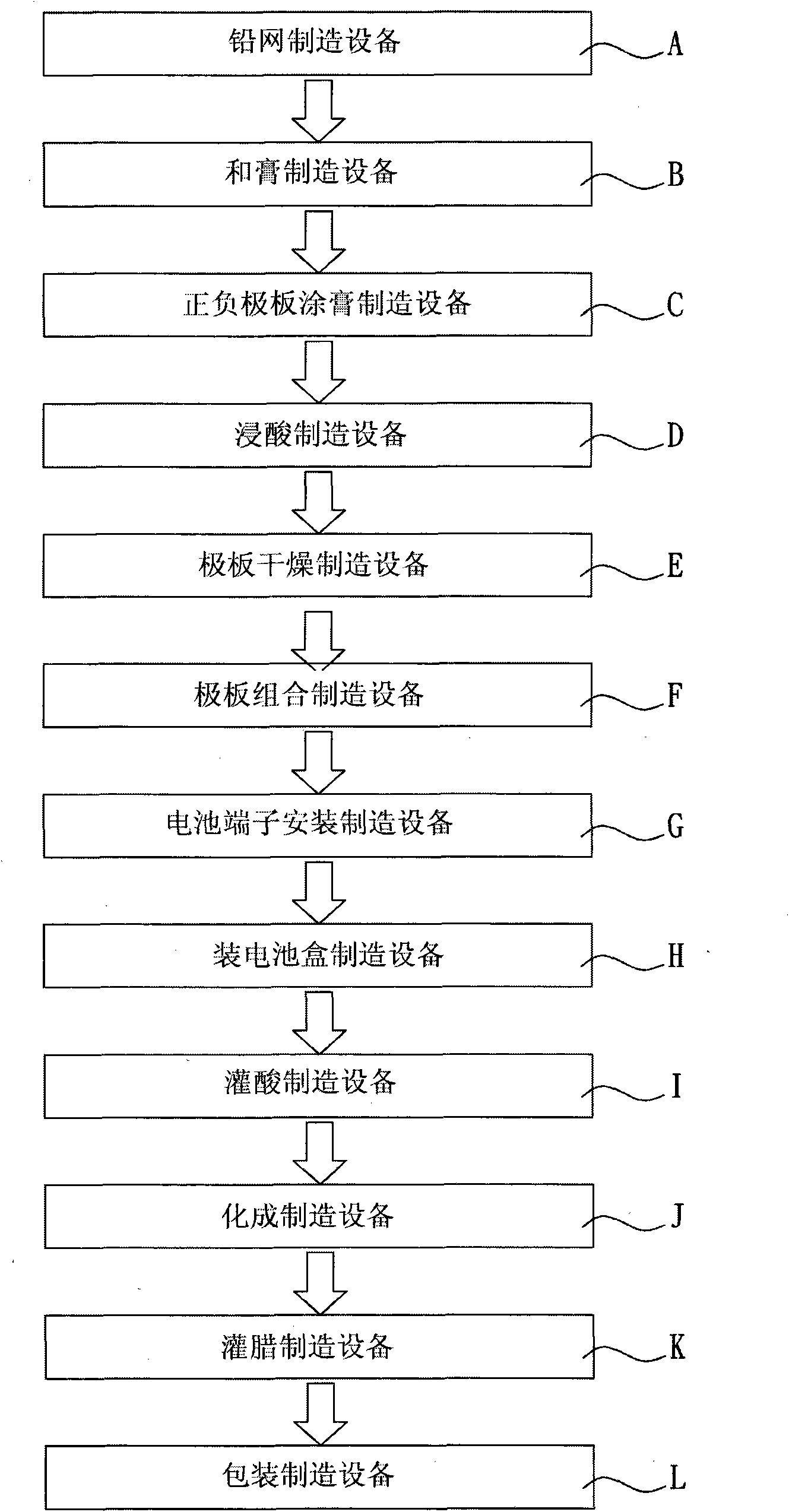

[0052] refer to figure 1 As shown, the horizontal battery production system provided by the present invention includes in order: a lead grid manufacturing equipment A, a paste manufacturing equipment B, a positive and negative plate paste manufacturing equipment C, a pickling manufacturing equipment D, A pole plate drying manufacturing equipment E, a pole plate assembly manufacturing equipment F, a battery terminal installation manufacturing equipment G, a battery box manufacturing equipment H, an acid filling manufacturing equipment I, a chemical formation manufacturing equipment J, a wax filling manufacturing equipment K and a packaging manufacturing equipment L.

[0053] Wherein, the lead mesh manufacturing equipment A uses an automatic lead wrapping ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com