Thermal management method and device for power battery pack with function of automatically controlling non-steady-state temperature field

A power battery pack and power battery technology, which is applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of increasing the weight of battery packs, large structural space, independent heating and cooling units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

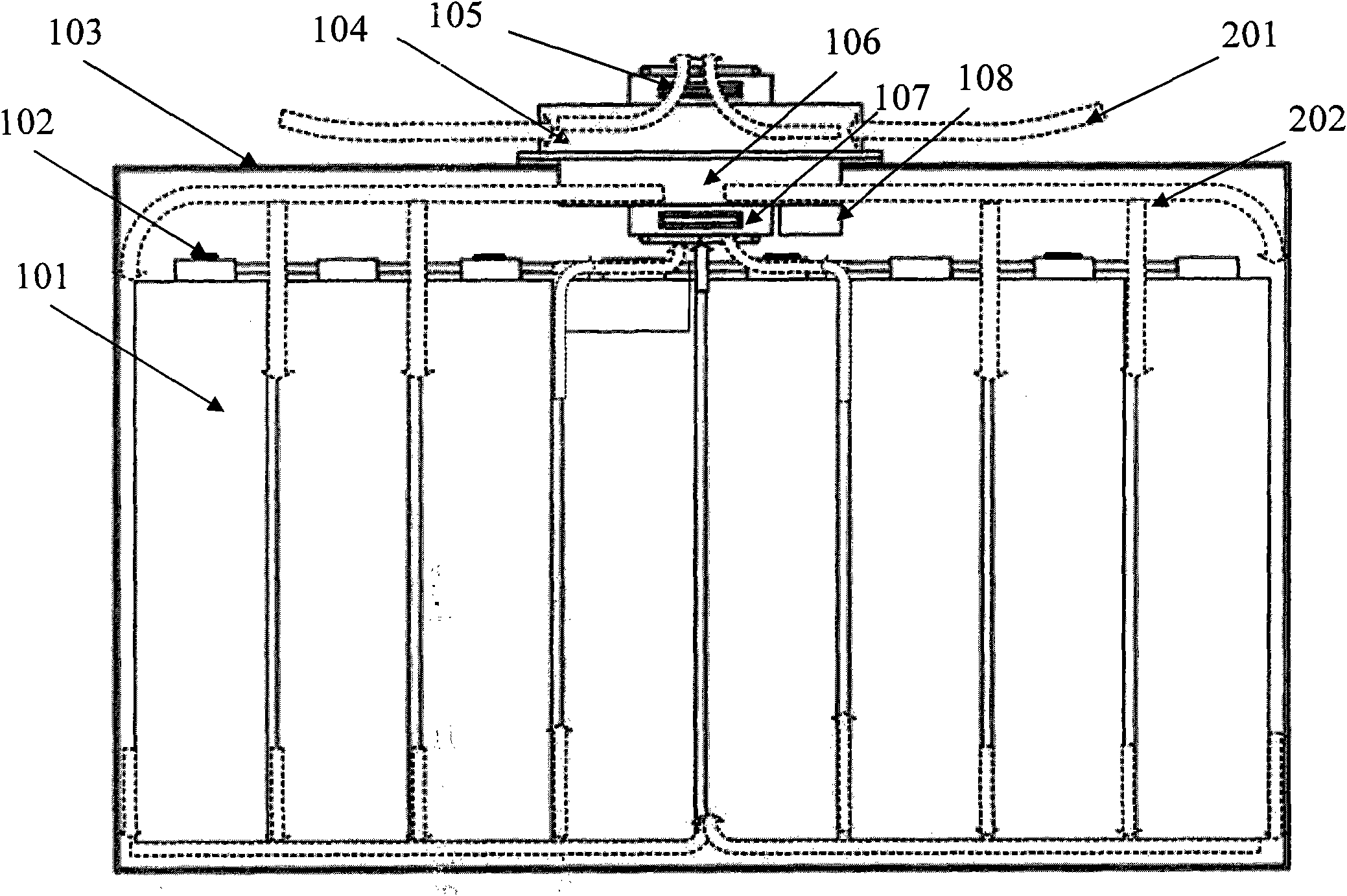

[0030] The power battery cell 101 is placed in the battery pack 103, and the temperature acquisition unit 102 is distributed on the pole of the power battery cell 101, and the hot end piece 104 of the semiconductor refrigeration heater and the external circulation fan 105 are placed outside the battery pack 103 , for heat transfer with the outside air. The cold end piece 106 of the semiconductor refrigeration heater and the internal circulation fan 107 are placed inside the battery pack 103 to perform air circulation and heat transfer in the battery pack 103 . The controller 108 of the thermal management system is integrated on the cold end piece 106 of the semiconductor refrigeration heater. The controller 108 controls the internal circulation fan 107, the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com