Air door gear clearance compensation device and method for bulk curing barn controller

A technology of gear clearance and dense curing room, which is applied in the fields of excitation or armature current control, application, tobacco preparation, etc. It can solve problems such as inconsistency, increased humidity control deviation, and unfavorable humidity control, so as to omit detection and improve stability. Performance and reliability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

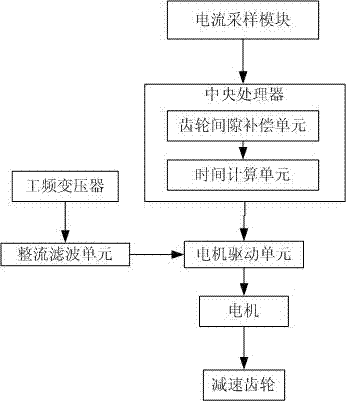

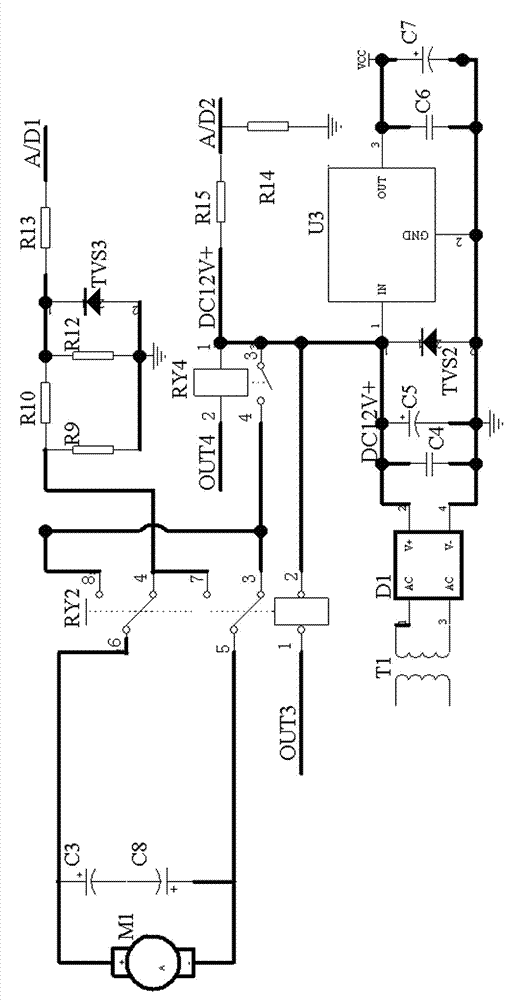

[0020] Such as figure 1 As shown, the present invention includes a power frequency transformer, a rectification filter unit connected to the power frequency transformer, a motor drive unit connected to the output end of the rectification filter unit, a DC motor connected to the motor drive unit, and a DC motor connected to drive the air door. The reduction gear is connected with the motor drive unit for controlling the central processing unit of the motor, and the output terminal is connected with the central processing unit of the DC motor current sampling unit, and the central processing unit is provided with the sampling value obtained according to the DC motor current sampling unit A gear gap compensation unit for determining whether there is a gear gap when the reduction gear is running, a time calculation unit connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com