Brightness decoration strip and special fastener of guide slot sealing strip

A technology of decorative strips and sealing strips, which is applied in the mechanical field, can solve problems such as deformation of the elastic body of the guide groove sealing strip, performance failure, and separation between the door outer cover plate and the guide groove sealing strip, so as to avoid extrusion deformation and separation seam or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing.

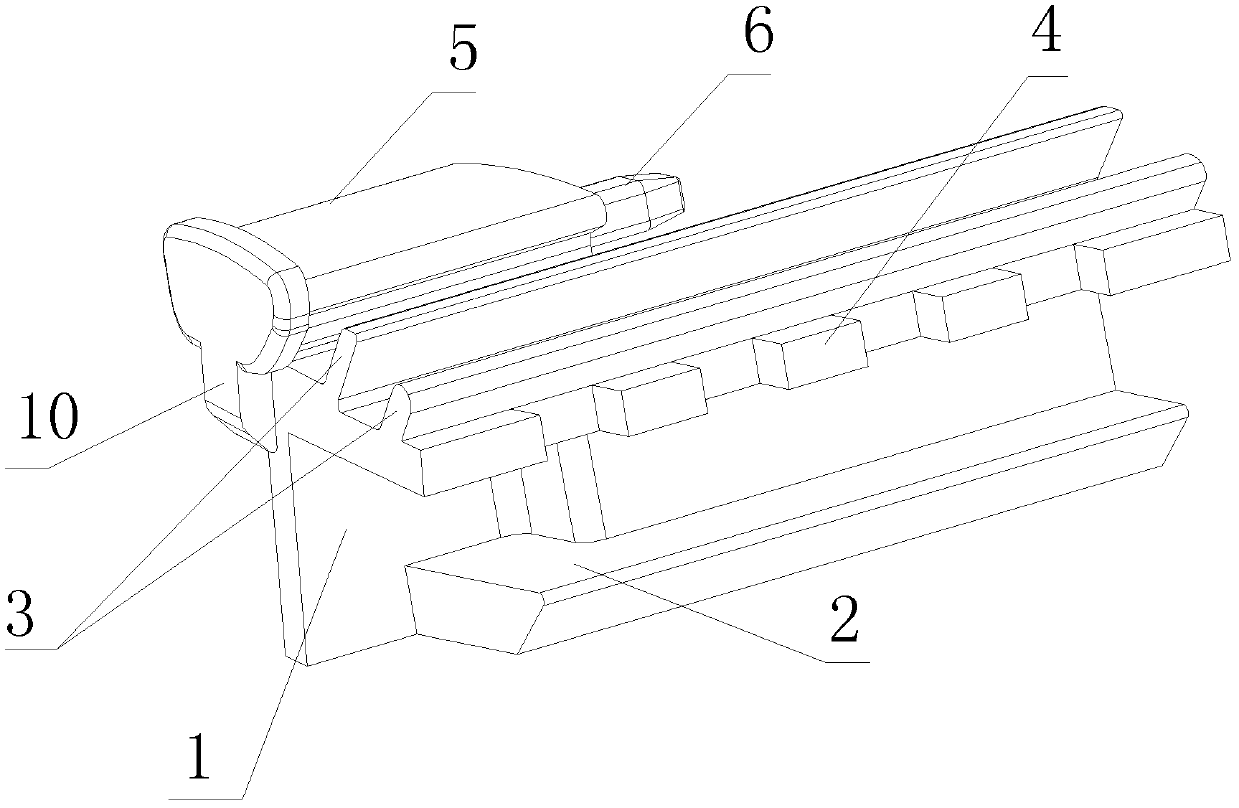

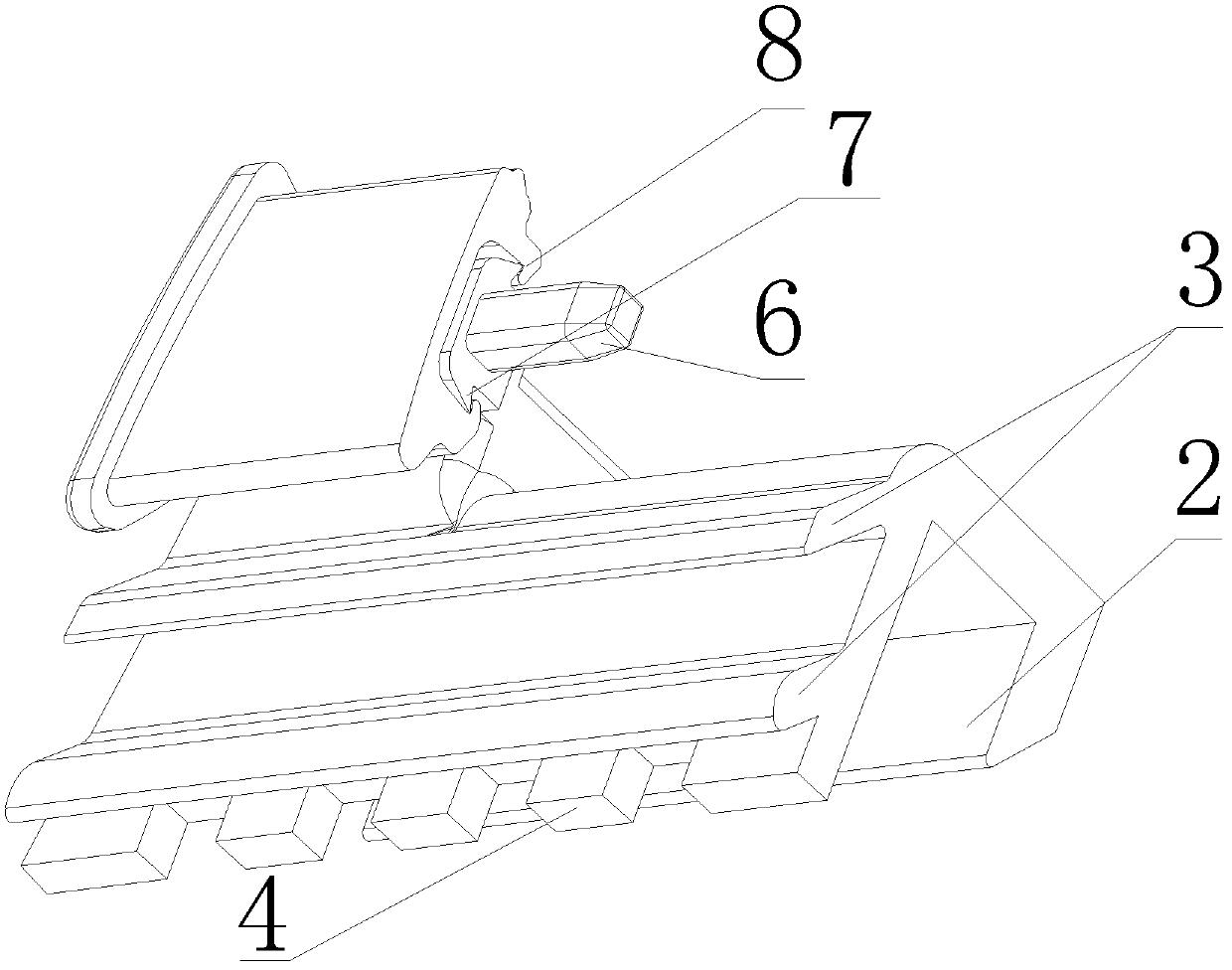

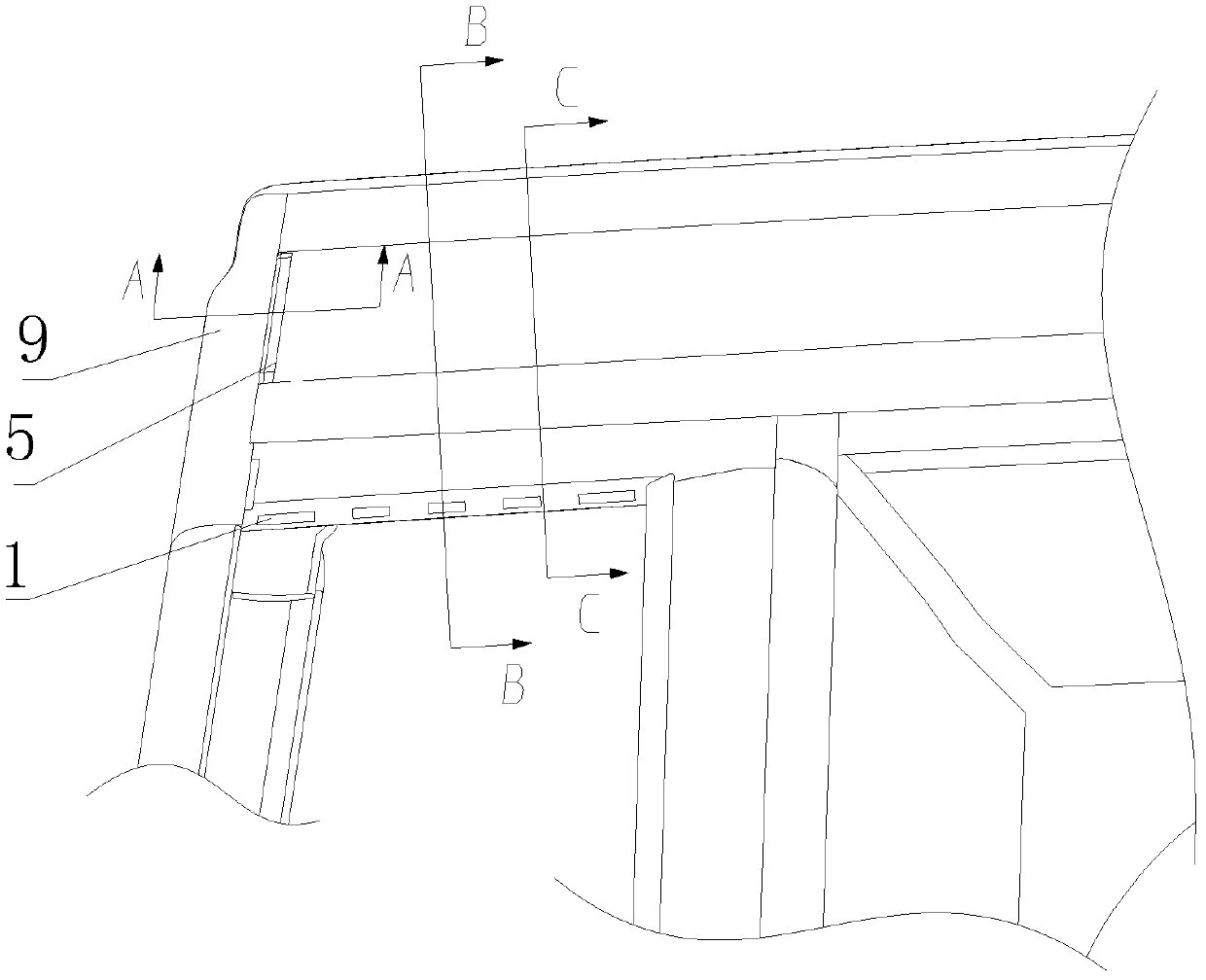

[0018] see figure 1 and figure 2 , the present invention includes an insert body including reinforcing ribs, step ribs, and process positioning ribs, and elastic clips including positioning pins, fixing pins, daughter cards, and mother cards. The bottom of the insert body 1 is provided with a process positioning rib 2, and the upper side of the top of the insert body 1 is provided with a reinforcing rib 3, which is composed of two guiding ribs, and the top front side of the insert body 1 is provided with a step rib 4 , the elastic clip 5 is arranged above the rear side of the insert body 1, the left side of the insert body 1 is provided with a positioning pin 10, and the right side of the insert body 1 is provided with a fixed pin 6, and one end of the fixed pin 6 is connected with the insert The body 1 is connected and molded inside the corner of the guide groove sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com