Dry hanging design structure of assembly type aluminum plate curtain wall and mounting method thereof

A design structure and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of wasteful construction efficiency and surface utilization, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

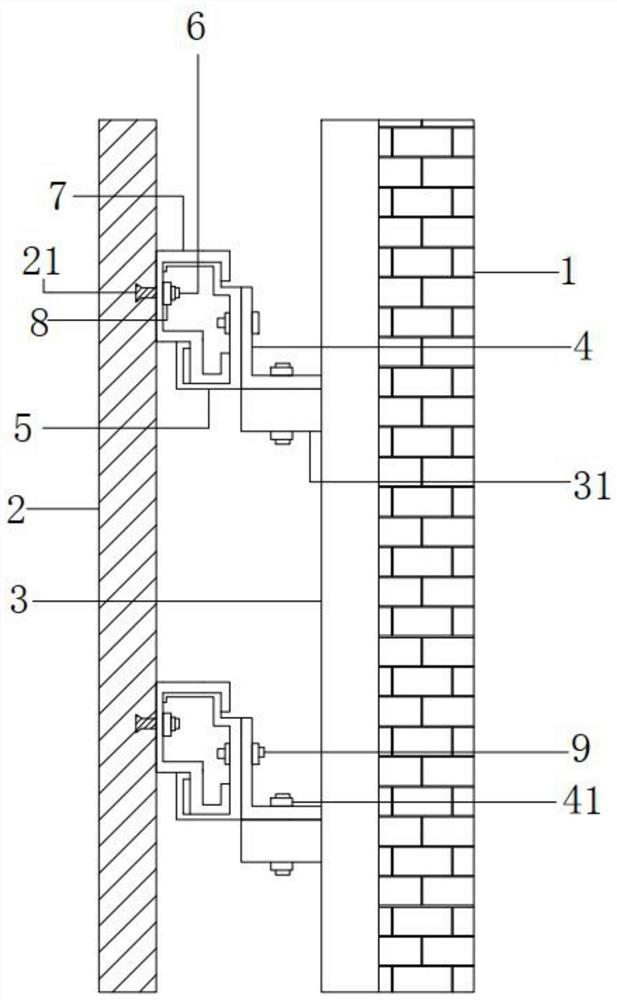

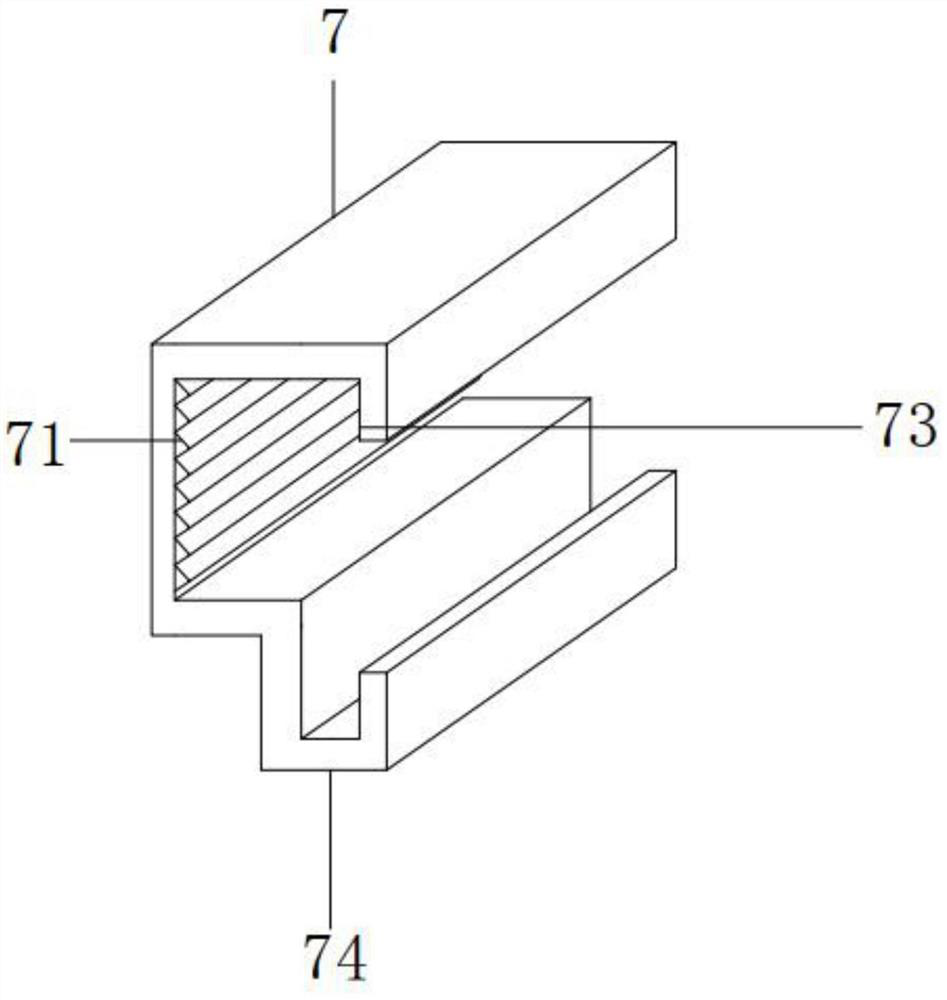

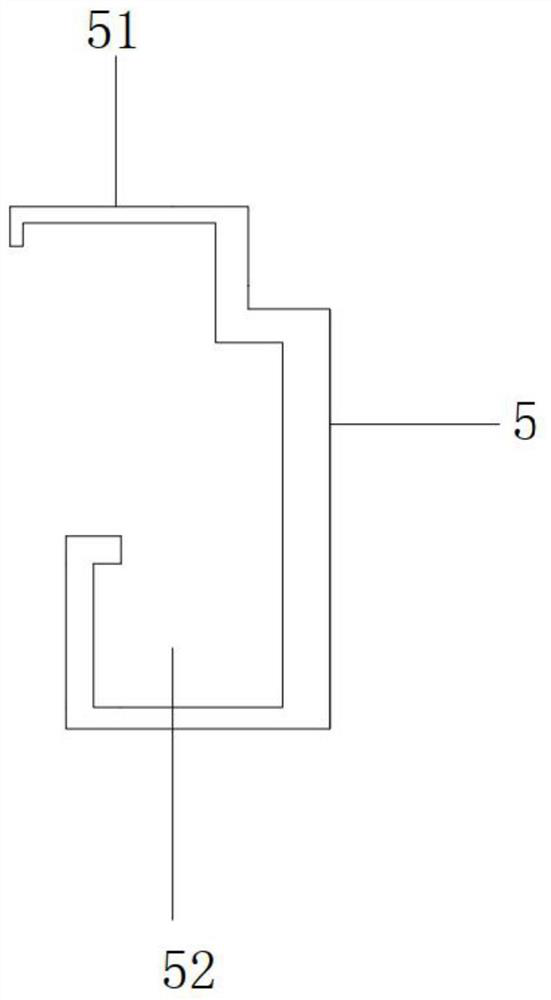

[0031] see Figure 1 to Figure 5 , the figure shows a dry-hanging design structure of an assembled aluminum curtain wall provided by Embodiment 1 of the present invention. The wall base 1 and the aluminum plate 2 connected to the wall base 1 are arranged on the wall base 1. Keel 3, several auxiliary keels 31 are installed on the main keel 3, several auxiliary keels 31 are equidistantly arranged along the length direction of the main keel 3, and several connecting pieces 4 are connected on the auxiliary keel 31, and the first pendant 5 is connected on the connecting piece 4 , the aluminum plate 2 is provided with a plurality of mounting holes 21, the mounting holes 21 are provided with expansion bolts 6, the expansion bolts 6 are pierced with a second pendant 7, the second pendant 7 is provided with a first serrated surface 71, the second pendant 7 One side of the limit washer 8 is provided with a second serrated surface 81 matching the first serrated surface 71, and one side o...

Embodiment 2

[0044] see Figure 1 to Figure 5 , the figure shows a dry-hanging design structure and installation method of a prefabricated aluminum curtain wall provided by Embodiment 2 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments Technical solution: the bottom of the mounting hole 21 is dovetail-shaped. Through the setting of the above structure, the stability of the expansion bolt connection can be improved.

Embodiment 3

[0046] see Figure 1 to Figure 5 , the figure shows a dry-hanging design structure and installation method of a prefabricated aluminum curtain wall provided by Embodiment 3 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments Technical solution: the second pendant 7 is provided with an adjustment hole 72, the adjustment hole 72 is set along the height direction of the second pendant 7, the expansion bolt 6 is penetrated in the adjustment hole 72, and the adjustment hole 72 is a waist-shaped hole. Through the setting of the above structure, the up and down position of the second pendant can be adjusted, so that the installation accuracy can be improved, and the wall surface can be made more orderly and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com