A frequency-selective high-temperature-resistant resin-based wave-transparent composite material and its preparation method

A high-temperature-resistant resin and frequency-selective technology, which is applied in metal material coating process, coating, melt spraying, etc., can solve frequency-selective surface film bubbling failure, difficulty in meeting electrical performance design requirements, and surface film adhesion Problems such as difficult process, to avoid block bonding and seam problems, small square resistance, excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

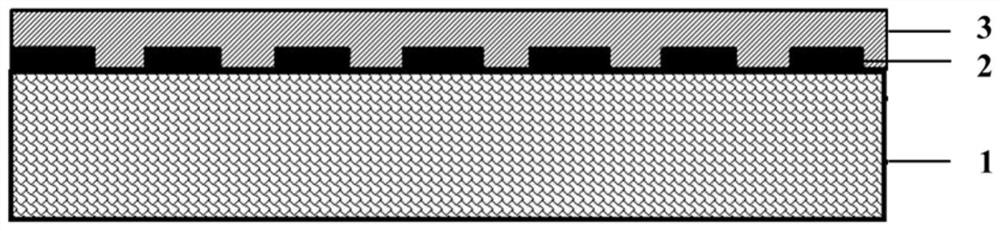

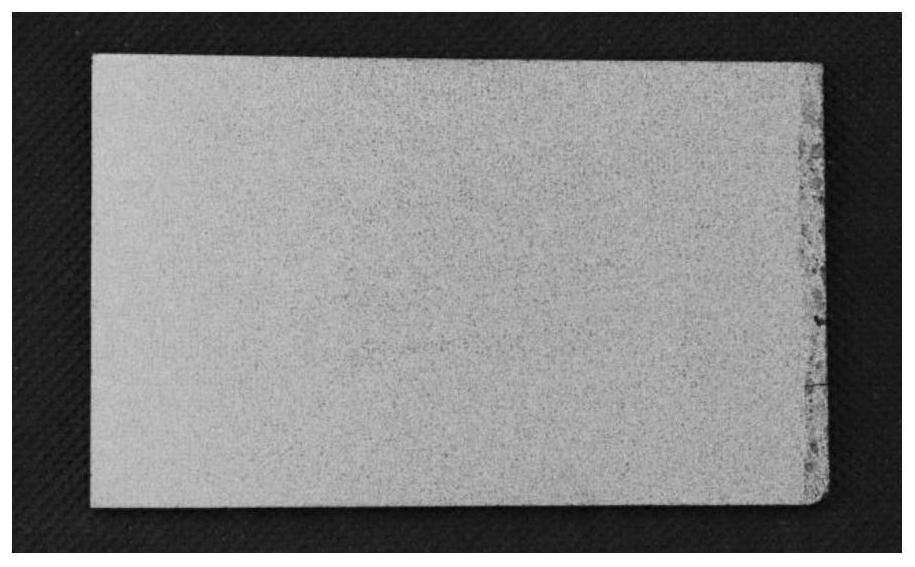

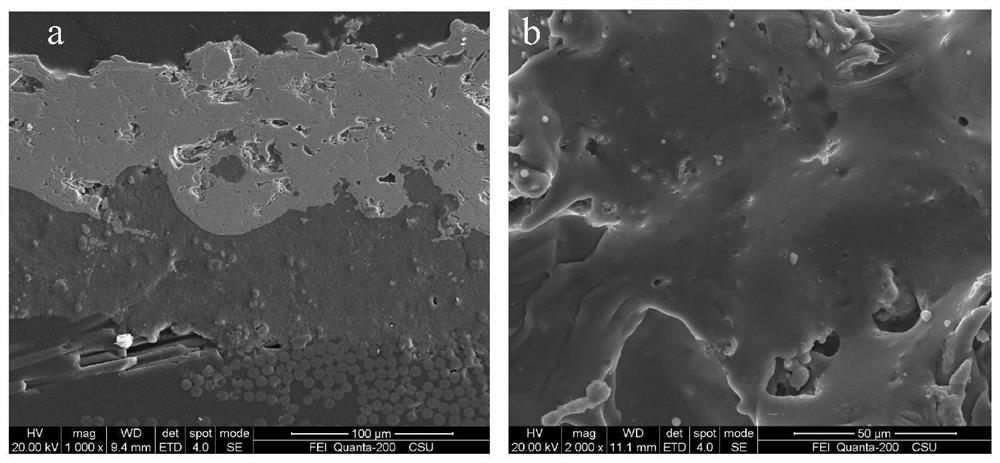

[0045] Such as figure 1 As shown, a flat plate-shaped frequency-selective high-temperature-resistant resin-based wave-transparent composite material includes three layers, including fiber-reinforced high-temperature-resistant resin-based composite material bottom layer 1, high-temperature frequency-selective surface interlayer 2 and anti-ablation / heat insulation / low dielectric surface layer 3, fiber reinforced high temperature resistant resin matrix composite material bottom layer 1 is quartz fiber reinforced polyimide composite material, high temperature frequency selective surface interlayer 2 is pores prepared by atmospheric plasma spraying process and laser processing process 8% Al coating, the thickness of the Al coating is about 50 μm, the anti-ablation / heat insulation / low dielectric surface layer 3 is a mullite coating with a porosity of 10% prepared by the atmospheric plasma spraying process, The coating thickness is 50 μm.

[0046] The preparation method of the a...

Embodiment 2

[0056] Such as Image 6 As shown, an axisymmetric tapered frequency-selective high-temperature-resistant resin-based wave-transparent composite material includes three layers, including fiber-reinforced high-temperature-resistant resin-based composite material bottom layer 1, high-temperature frequency-selective surface interlayer 2 and anti- Ablation / heat insulation / low dielectric surface layer 3, fiber reinforced high temperature resistant resin matrix composite material bottom layer 1 is made of quartz fiber reinforced polyarylene composite material, high temperature frequency selective surface interlayer 2 is atmospheric plasma spraying process and laser processing technology The prepared Cr coating with a porosity of 10%, the thickness of the Cr coating is about 45 μm, and the anti-ablation / heat insulation / low dielectric surface layer 3 is a cordierite coating with a porosity of 15% prepared by the atmospheric plasma spraying process. layer with a coating thickness of 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com