Integrated decelerating clutch for washing machine motor

A technology of deceleration clutch and washing machine, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of not much improvement of motor efficiency, complicated installation and connection, and many connecting parts of main parts, so as to improve the service life, Improved reliability and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

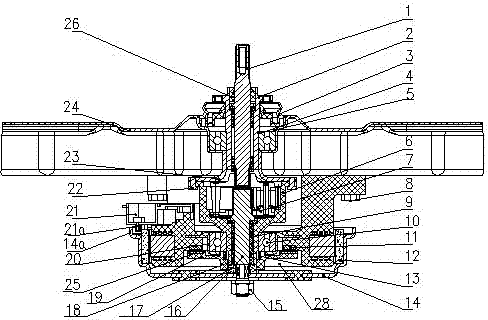

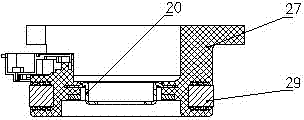

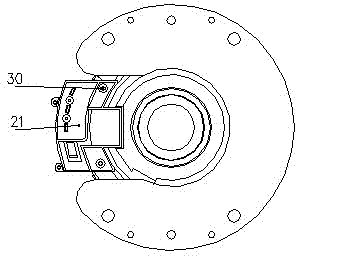

[0024] Such as Figure 1 to Figure 3 As shown, the integrated washing machine motor deceleration clutch of the present invention includes an input shaft 16, a stator 27, and an outer rotor 14 fixedly connected to the lower end of the input shaft 16, wherein the outer circumference of the outer rotor 14 extends upwards with the input shaft 16 to form a fixed stator. 27 inner cavity 28, the upper end of the stator 27 protrudes from the inner cavity 28 and is fixedly connected with the upper housing 24, and the Hall element feedback assembly 21 is installed on the shoulder made of the stator 27, and the Hall element feedback assembly 21 The lower edge is in clearance fit with the upper edge of the outer rotor 14 , and the Hall element feedback assembly 21 measures and controls the rotational speed of the outer rotor 14 . In the present invention, the motor stator 27 is directly installed on the lower part of the upper casing 24 through the stator fixing screws 8, and the body...

no. 2 example

[0033] Such as Figure 4 As shown, the brake wheel 6 of the present invention is transformed into a metal clutch shaft 32, and the connecting plate 23 is also transformed into a metal brake wheel 31, and the metal brake wheel 31 and the metal clutch shaft 32 are connected as one piece by riveting, and the metal brake The wheel 31 is interference fit with the dehydration shaft 2, the second oil bearing 33 and the third oil bearing 35 are arranged between the input shaft 16 and the brake wheel 6, and the second oil bearing 33 and the third oil bearing 35 are sealed and installed with Intermediate sealing ring 34. Other parts not described are the same as the first embodiment.

[0034] work process:

[0035] During washing machine washing: the electromagnetic coil 11 is not energized, and the clutch slider 19 slides downward under the spring force of the clutch spring 13, realizing the separation of the splines of the brake wheel 6 and the splines of the axle sleeve 17. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com