Double barrel series-unit production device for twisting steel strands

A production device and a technology for steel strands, applied in the field of steel strand manufacturing, can solve the problems of low strength and durability, increased equipment investment costs, incompatibility with the production of steel strands of different specifications, etc., so as to reduce investment costs and improve The effect of production efficiency and unit manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

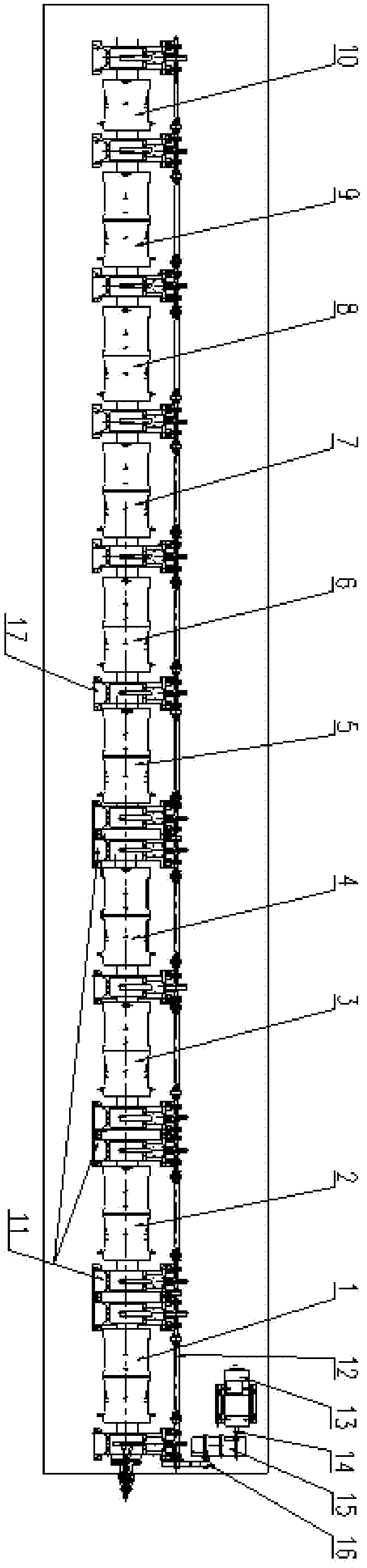

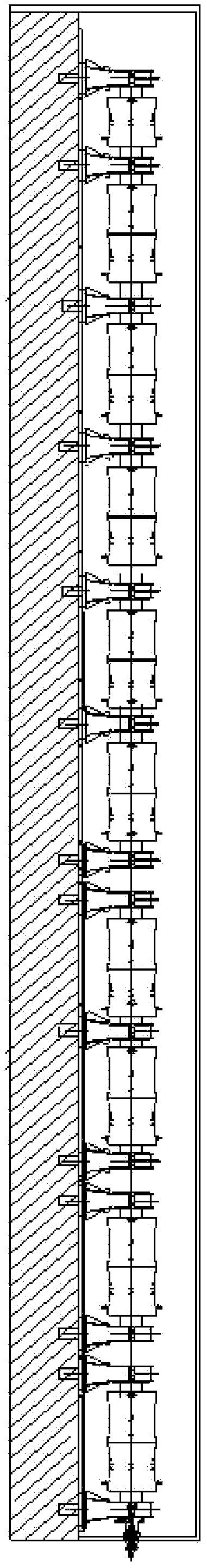

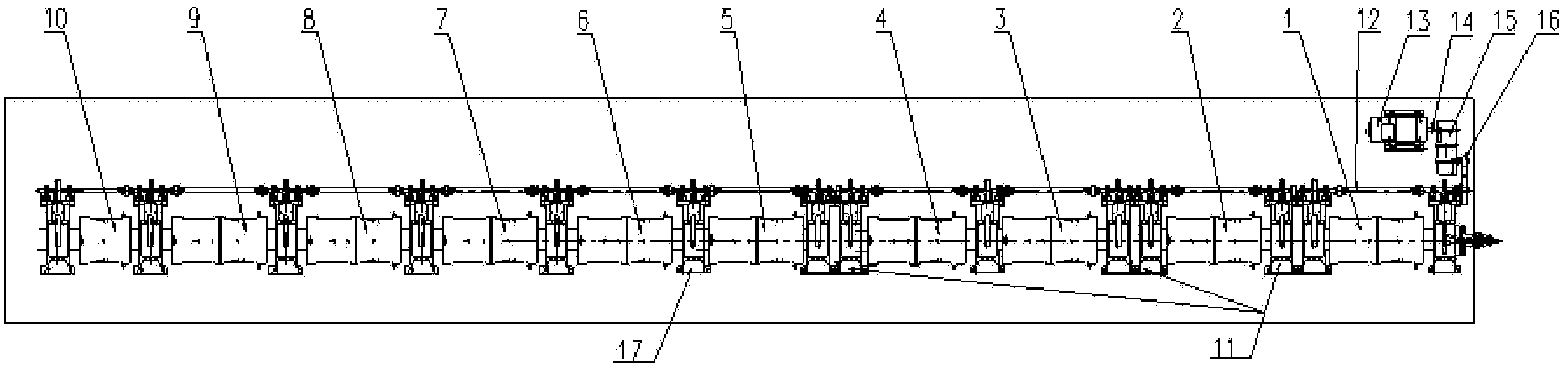

[0010] like figure 1 Shown in, a kind of two-position barrel series unit type steel strand twisting production device of the present invention mainly consists of a barrel (1), b barrel (2), c barrel (3), d barrel (4 ), cylinder e (5), cylinder f (6), cylinder g (7), cylinder h (8), cylinder i (9), cylinder j (10), clutch (11), main Transmission shaft (12), variable frequency motor (13), shaft coupling (14), gearbox (15), belt pulley (16), connecting seat (17) constitute; a cylinder body (1) and b cylinder body (2 ), cylinder b (2) and cylinder c (3), cylinder d (4) and cylinder e (5) are connected through clutches (11), and the remaining cylinders are connected through connecting seats (17) , the center line of the cylinder unit should be consistent; the variable frequency motor (13) is connected with the gearbox (15) through the coupling (14), and the gearbox (15) is connected with the main drive shaft (12) through the pulley (16), The main transmission shaft (12) is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com