Nickel-titanium shape memory alloy sheet with gradient grain structure

A memory alloy and plate technology, applied in the field of alloy materials, can solve the problems of high temperature oxidation, poor biocompatibility and high deformation resistance of plates, and achieve the effect of achieving coordination and matching and realizing biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

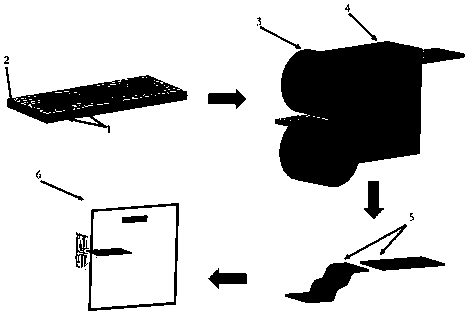

[0032] Embodiment 1: For the nickel-titanium shape memory alloy plate of 2.5mm thick Ni50.9at%Ti49.1at%, adopt the following process steps and parameters:

[0033] (1) Grind one piece of nickel-titanium shape memory alloy plate with an atomic ratio of Ni50.9at%Ti49.1at% of 200mm*120mm*2.5mm to remove burrs and oxide scales, and two pieces of Q235 low-carbon sheet of 200mm*120mm*3mm The steel plate is polished to remove burrs and scale, and then the two are stacked and compounded according to the "sandwich" structure, and are wound and fixed with steel wire at the end of the rolling mill.

[0034] (2) Coat the surface of the prepared composite sheet with graphite to reduce the friction coefficient of the friction sheet, and then transfer it to the rolling mill, adjust the speed of the upper and lower rolls to 25m / min, and the reduction of the rolling pass to 50% (guarantee nickel-titanium The thinning rate of the shape memory alloy sheet is not less than 35%). Under the action ...

Embodiment 2

[0036] Embodiment 2: For the nickel-titanium shape memory alloy plate of 3.0mm thick Ni47at%Ti50at%Fe3at%, adopt following process step and parameter:

[0037] (1) Grind a 200mm*120mm*3.0mm nickel-titanium shape memory alloy plate with an atomic ratio of Ni47at%Ti50at%Fe3at% to remove burrs and oxide scales, and 2 pieces of 200mm*120mm*3.5mm Q235 low carbon steel The plates are polished to remove burrs and oxide scales, and then the two are stacked and compounded according to the "sandwich" structure, and are wound and fixed with steel wires at the end of the rolling mill.

[0038] (2) Coat the surface of the prepared composite sheet with graphite to reduce the friction coefficient of the friction sheet, and then transfer it to the rolling mill, adjust the speed of the upper and lower rolls to 35m / min, and the reduction of the rolling pass to 43% (guaranteed nickel-titanium The thinning rate of the shape memory alloy sheet is not less than 35%). Under the action of rolling fri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com