Efficient hemostatic material capable of promoting wound healing and preparation method thereof

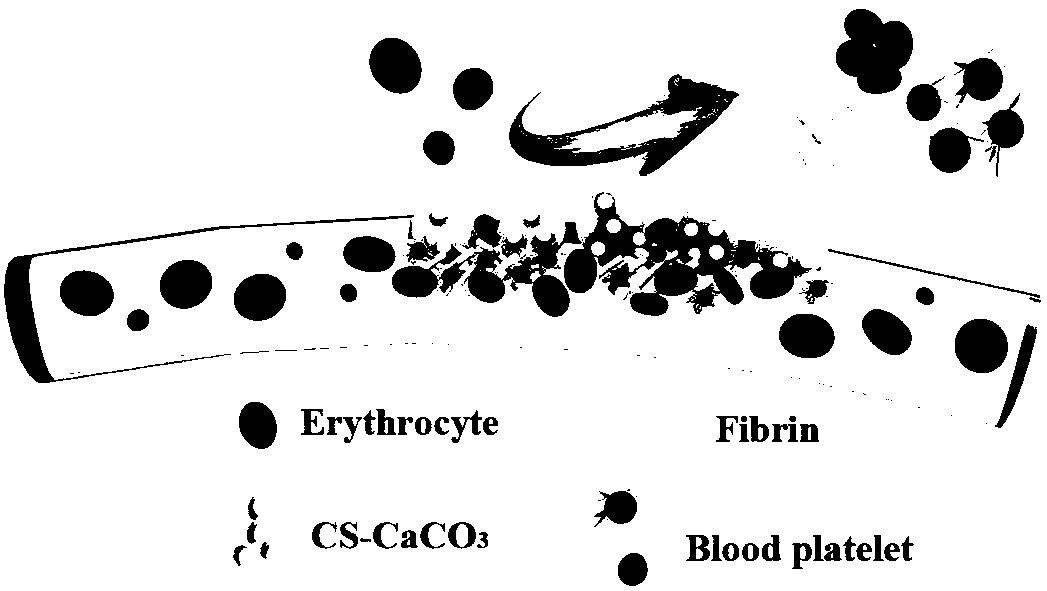

A hemostatic material and wound healing technology, applied in the field of high-efficiency hemostatic materials and their preparation, can solve the problems of lack of hemostatic efficiency and biocompatibility characteristics, and achieve the effects of promoting wound healing, shortening wound healing time, and high coagulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

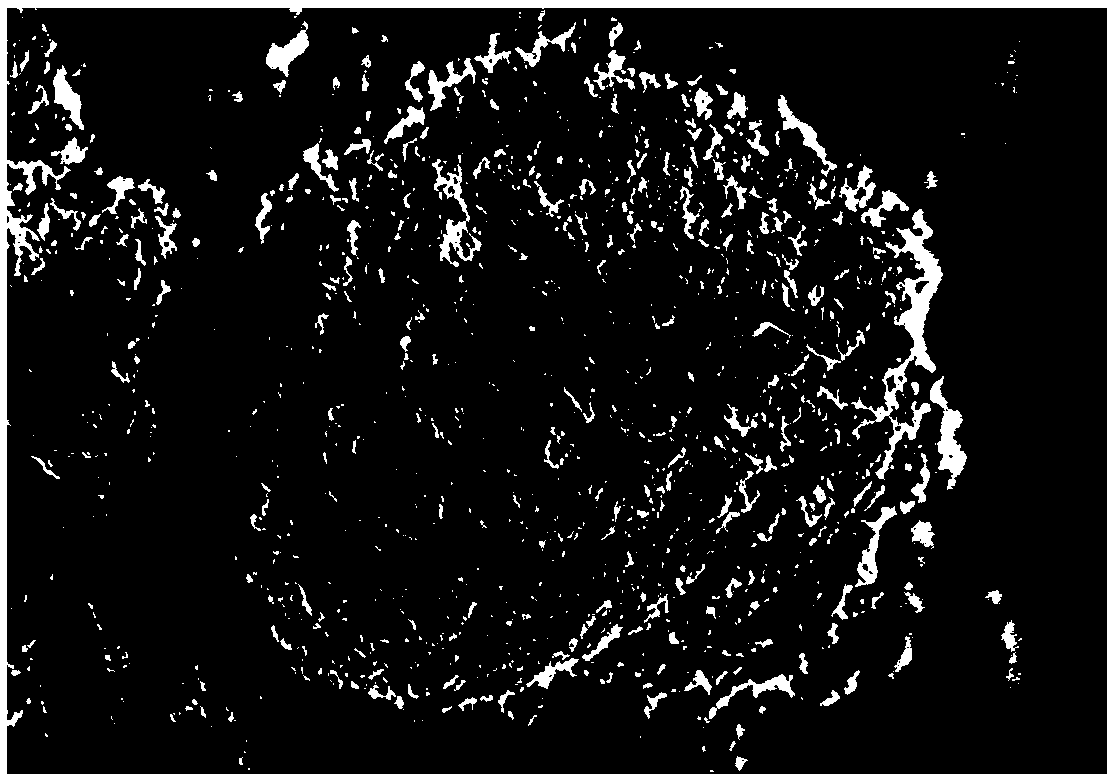

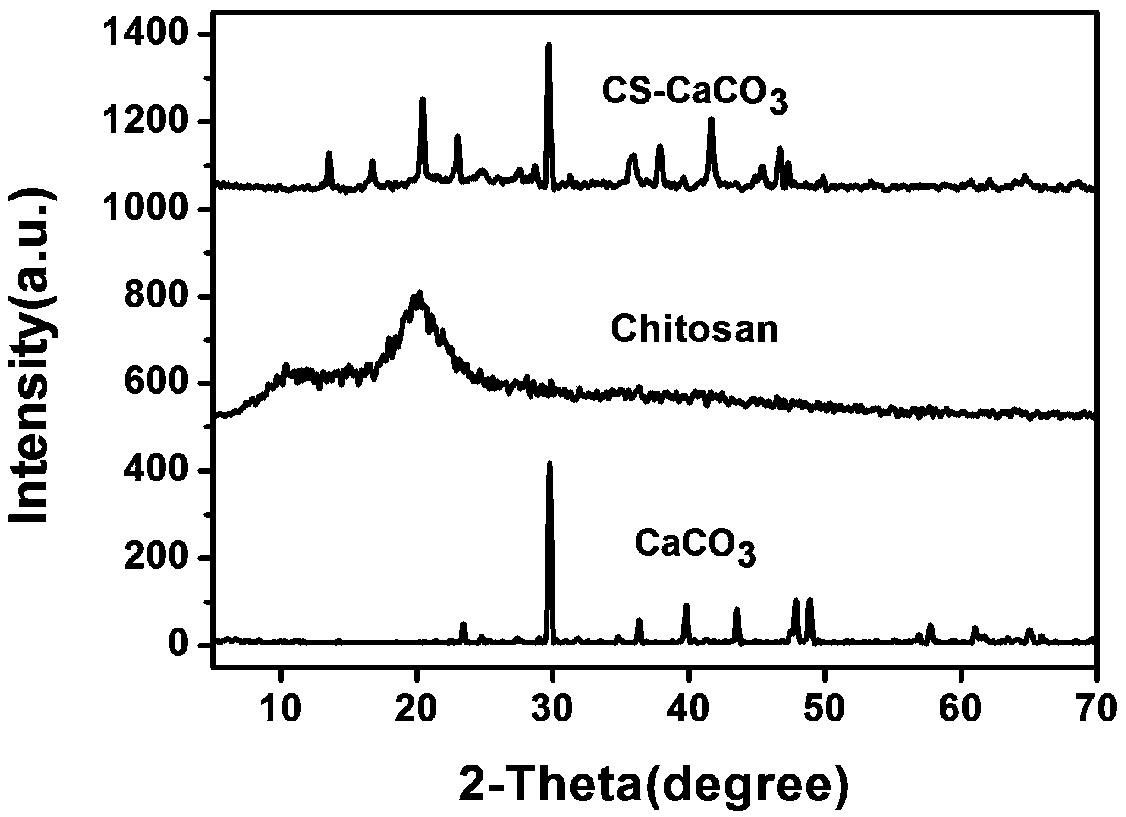

[0029] (1) Spherical porous CaCO 3 Preparation of powder: Weigh 16.6g CaCl successively 2 , 15.6g Na 2 CO 3 , were fully dissolved in 300mL distilled water. Under vigorous stirring at room temperature, the Na 2 CO 3 Solution (0.1M) was quickly poured into CaCl 2 (0.1M) solution. The resulting precipitate was washed 3 times with distilled water, filtered with suction, and dried in air at room temperature.

[0030] (2) Dissolving of 1% chitosan: Weigh 5g chitosan in 1L flask, add 500mL distilled water, under the condition of magnetic stirring, dropwise add the existing 1wt% CH 3 COOH solution 5g. Continue to stir for 12 hours until the chitosan is fully dissolved and the solution is clear and transparent.

[0031] (3)CaCO 3 Compounding with chitosan: under the effect of magnetic stirring, the CaCO prepared by 10g step (1) 3 The powder was dispersed in 200mL distilled water, then poured into 200mL chitosan solution, and kept stirring until the powder was fully disperse...

Embodiment 2

[0035] (1) Spherical porous CaCO 3 Preparation: Weigh 11.0g CaCl in turn 2 , 10.5g Na 2 CO 3 , were fully dissolved in 300mL distilled water. Under vigorous stirring at room temperature, the Na 2 CO 3 Solution (0.33M) was quickly poured into CaCl 2 (0.33M) solution. The resulting precipitate was washed 3 times with distilled water, filtered with suction, and dried in air at room temperature.

[0036] (2) Dissolution of 1% chitosan: Weigh 5g chitosan in a 1L flask, add 500mL distilled water, and add the existing 1% CH 3 COOH solution 5g. Continue to stir for 12 hours until the chitosan is fully dissolved and the solution is clear and transparent.

[0037] (3)CaCO 3 Compounding with chitosan: under the action of magnetic stirring, 10g CaCO 3 After the powder is decomposed in 200mL distilled water, pour into 200mL chitosan solution. Stir continuously until the powder is well dispersed in the solution and then freeze.

[0038] (4) Processing of the composite material:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com