Floating bridge removing method

A technology of floating bridge demolition method and bridge method, which can be used in building maintenance, construction, building construction and other directions, and can solve problems such as long construction time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

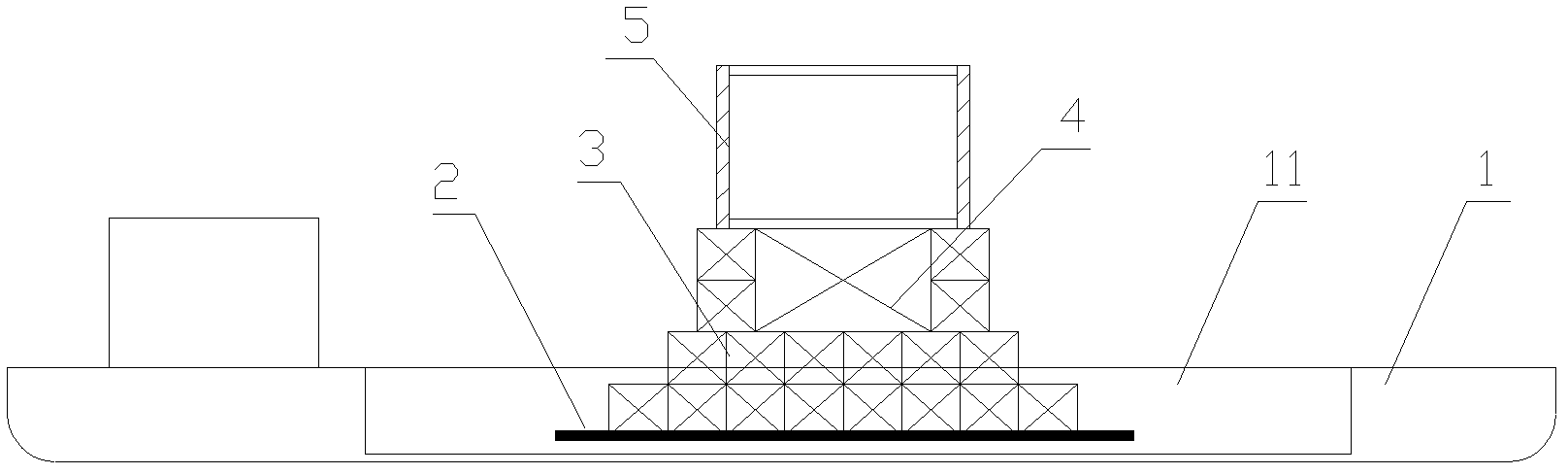

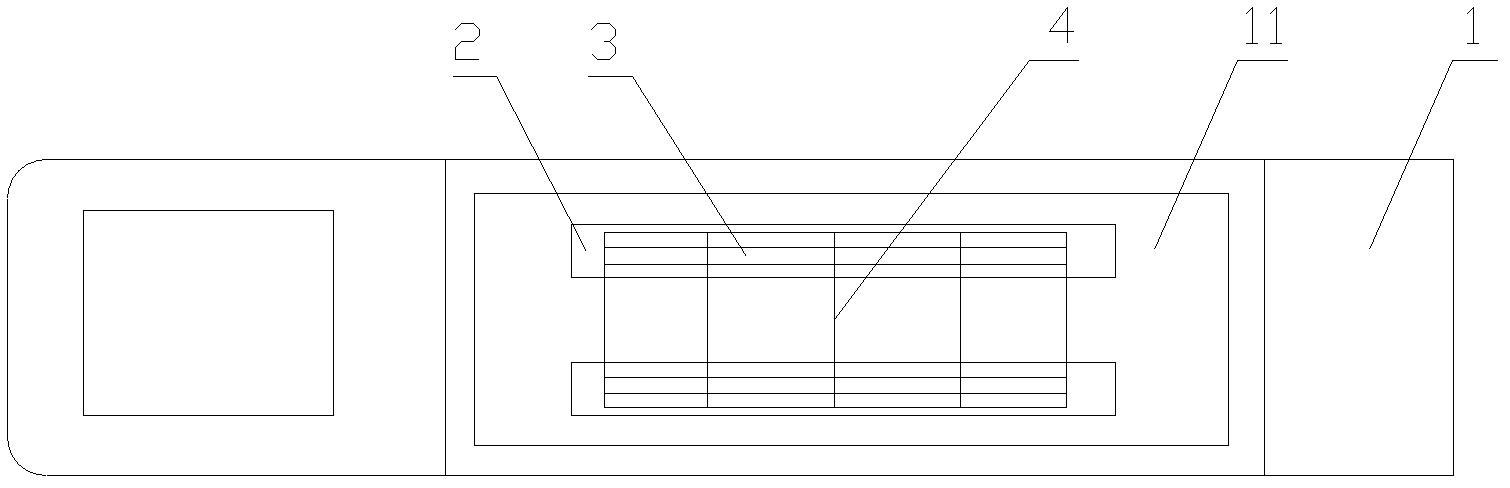

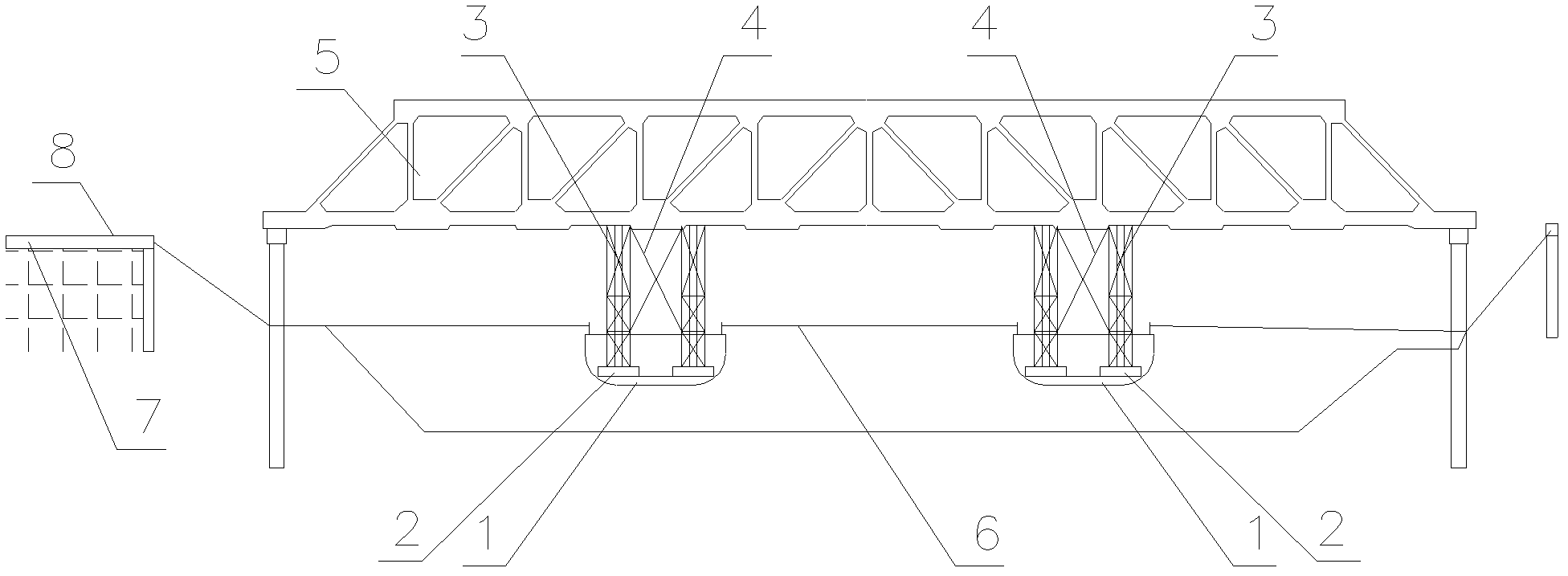

[0018] Combine Figure 1 to Figure 4 A detailed description of the embodiment of the floating bridge demolition method includes the following steps:

[0019] The first stage: the demolition of the old bridge deck in the construction stage, first remove the railings, then cut out the bridge deck, then remove the middle span concrete girder slab, and finally remove the side span girder slab; the specific process is to first seal the existing road, The bottom of the old bridge and the two bridges are equipped with safety protection nets. The old bridge components are manually removed by air compressors. The railings are removed first, and then the bridge deck paving; then the middle span concrete beam slabs are removed first, and then the side span beam slabs are removed. The connecting steel bars between the beam slab and the beam slab are cut by gas cutting, and the concrete in the screed is opened with a wind draft to reduce the binding and binding force between the beams and sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com