Three-in-one vertical desander and desanding process

A desander and three-in-one technology, applied in chemical instruments and methods, filtration and separation, mining fluids, etc., can solve problems such as difficulty in ensuring sealing performance, unavoidable disassembly of screen pipes, blockage of screen pipe flow area, etc., to achieve sealing Reliable, extended maintenance cycle, high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

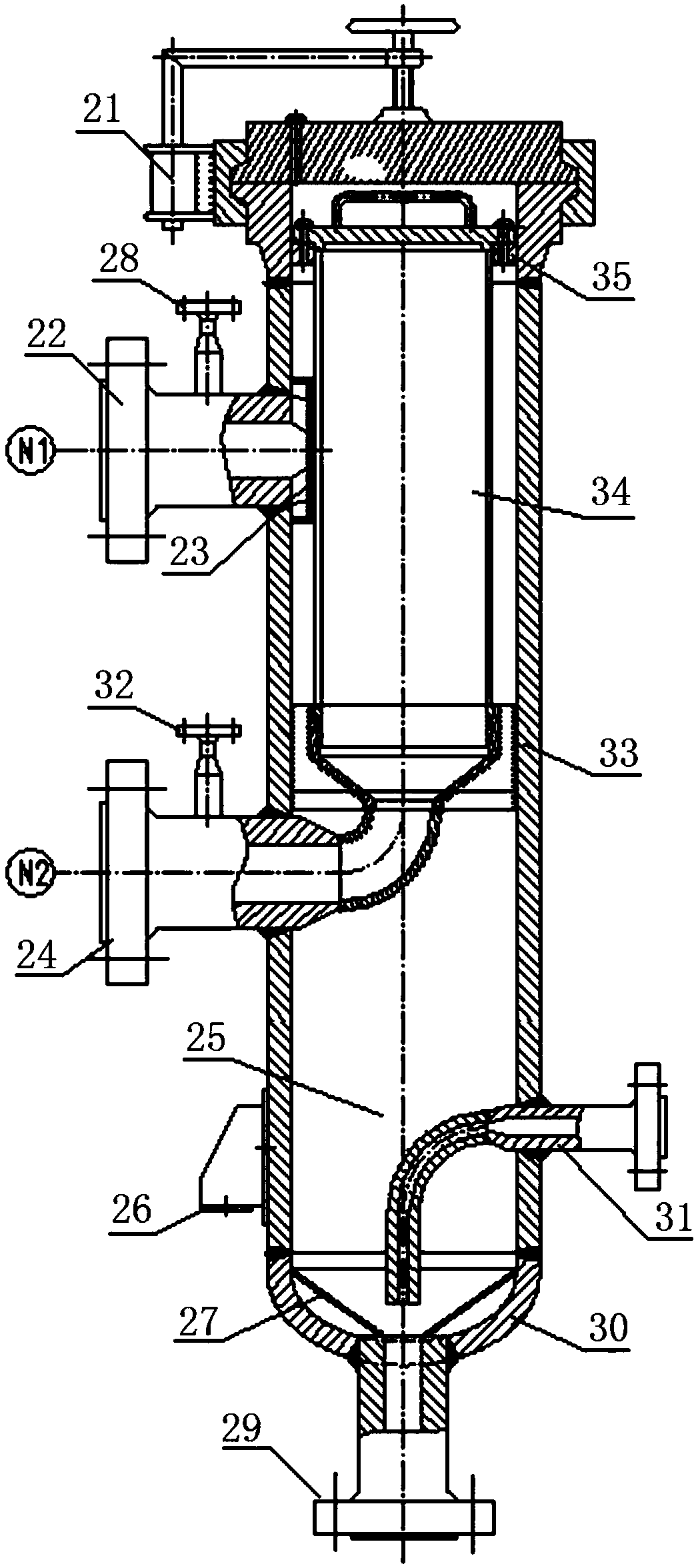

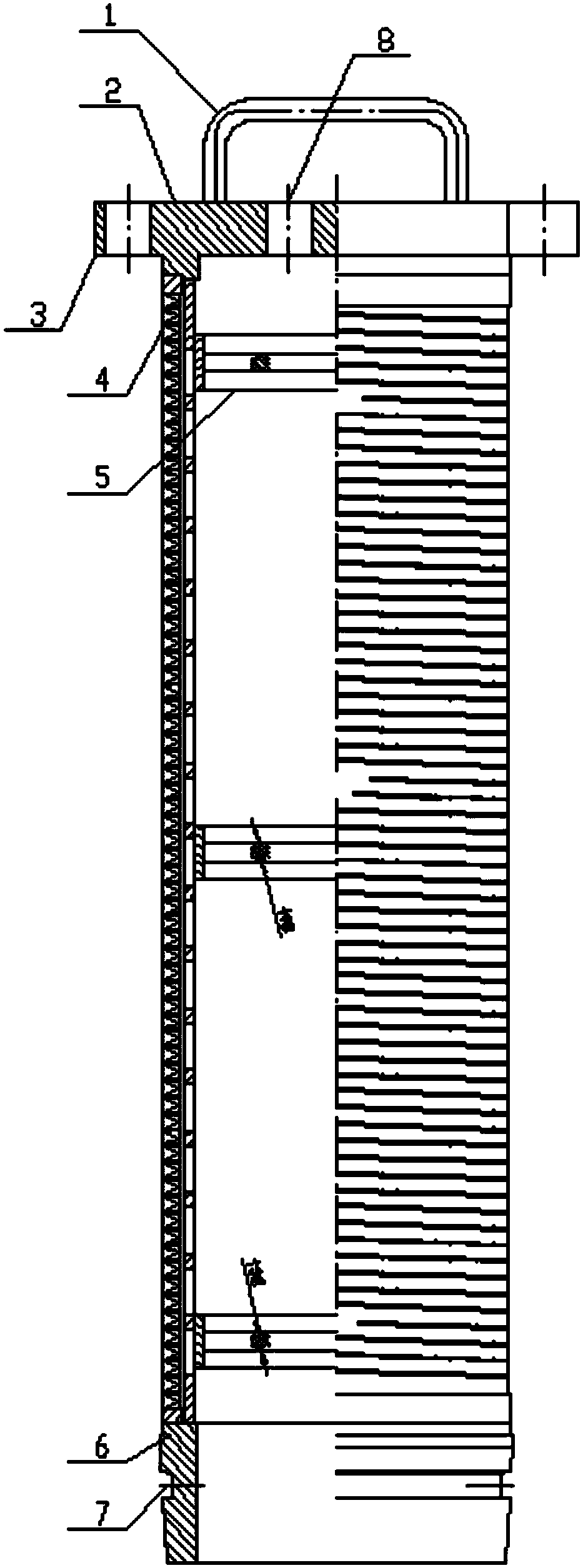

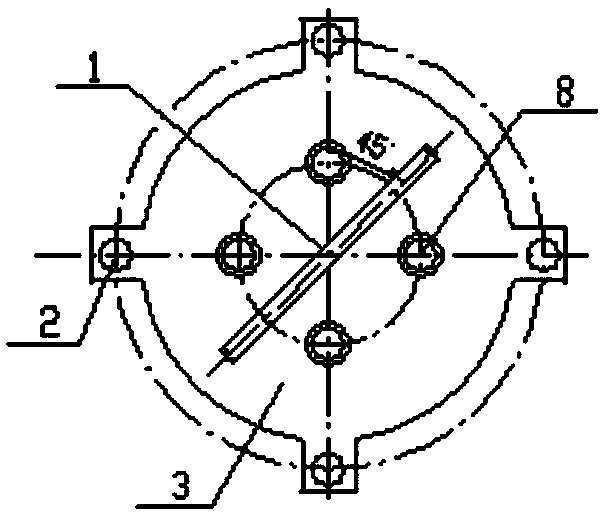

[0039] A three-in-one vertical desander, such as figure 1 As shown, it includes: quick opening blind plate 21, medium inlet 22, swirl guide device 23, medium outlet 24, sand storage space 25, ear support 26, conical funnel 27, inlet differential pressure gauge 28, sand discharge port 29 , head 30, recoil port 31, outlet differential pressure gauge 32, cylinder body 33, screen tube 34, cover lug 35, wherein:

[0040]A quick-opening blind plate 21 is installed on the top of the three-in-one vertical desander cylinder body 33 for new shale gas, a medium inlet 22 is installed on the upper part, a medium outlet 24 is installed on the middle part, a recoil outlet 31 is installed on the lower part, and a sand discharge outlet 29 is installed on the bottom . A swirl guide device 23 is set at the medium inlet 22, and a screen tube 34 is set inside the cylinder body 33. The screen tube 34 passes through a wedge-shaped structure and an O-ring at one end of itself, and the cover lug 35 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com