Construction method of waterproof leaking stoppage structure of building seam

A construction method and technology of building joints, which are applied in building structure, processing of building materials, construction, etc., can solve the problems of easy pollution of the environment, large amount of epoxy resin adhesive, waste of labor costs, etc., and achieve the goal of construction technology The effect of simplicity, small exposed area, and less man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

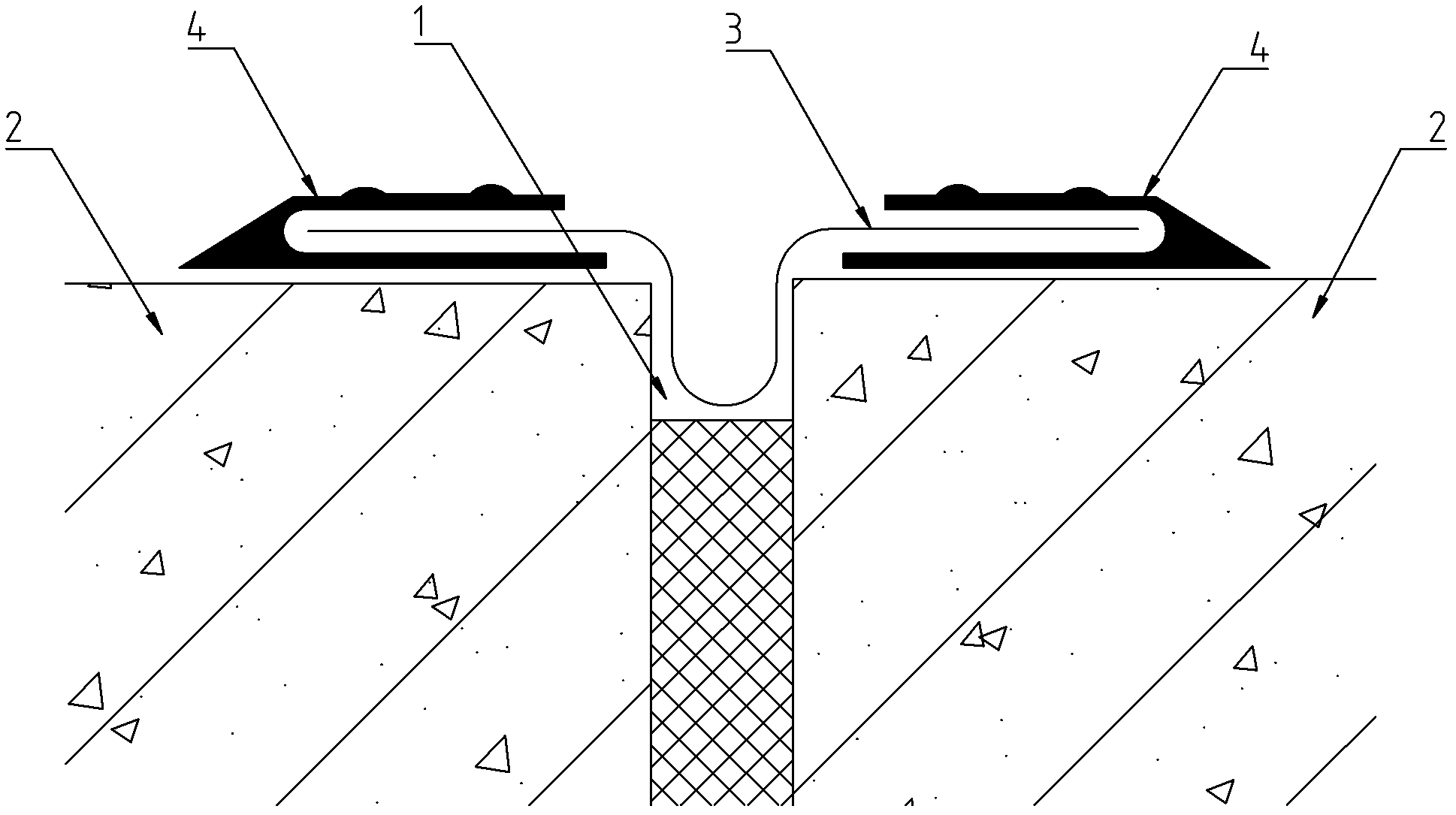

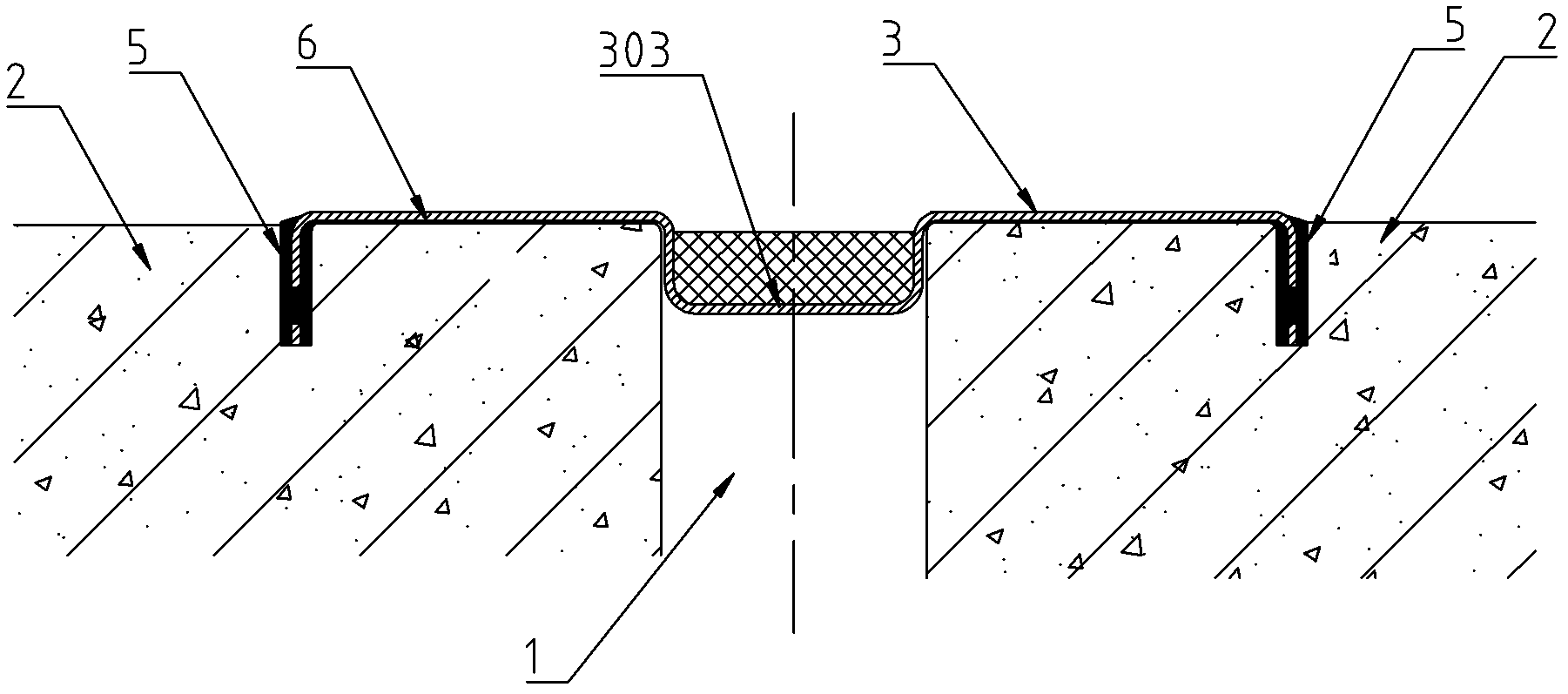

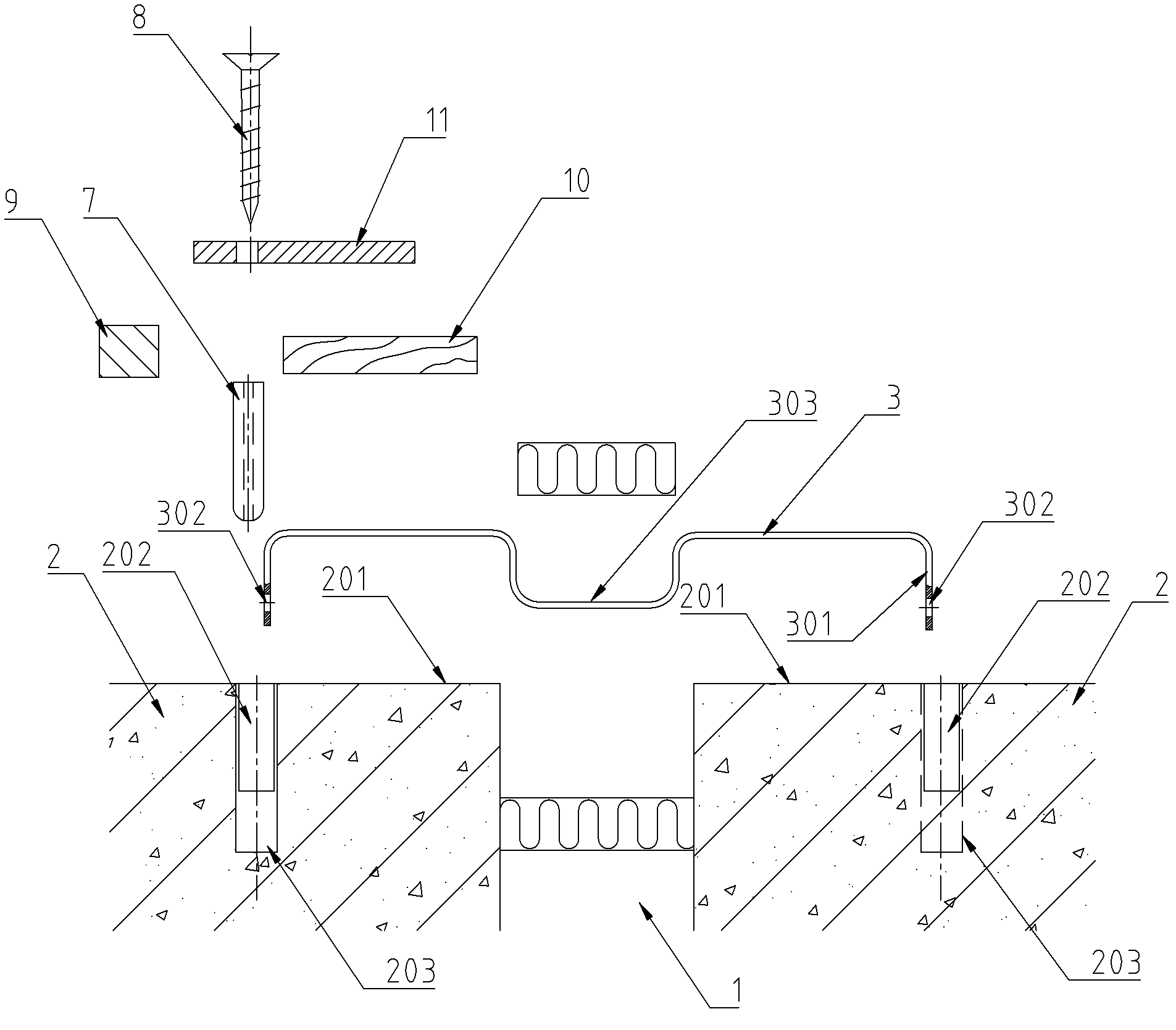

[0046] exist Figure 2 to Figure 5 In the shown embodiment of the building joint waterproofing and leak-stopping structure of the present invention, the building joint waterproofing and leak-stopping structure includes a building joint 1 , structures 2 located on both sides of the building joint 1 and a PVC coil waterstop 3 . Have the groove 202 parallel with building seam 1 on the water stop surface 201 of seam side structure body 2, the width of groove 202 is 5-6 millimeter, and the distance of groove 202 and building seam 1 is 50 millimeters to 100 millimeters. Both sides of the waterstop 3 have folded edges 301 bent downwards, and the folded edges 301 are inserted into the groove 202, and the groove 202 is filled with epoxy resin adhesive 5, and the epoxy resin 5 adhesive will seal the water. The hem 301 of the strap 3 is fixed in the groove 202 .

[0047] The flange 301 of the waterstop 3 has many anchor holes 302 along the length direction of the waterstop 3. The diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com