Brake anti-blocking screw drilling tool

A screw drilling tool and anti-blocking technology, applied in drilling tools, earth-moving drilling, drilling equipment, etc., can solve problems such as drilling tool blockage, well platform pollution, increased operating costs, etc., and achieve long service life, anti-blocking and anti-wear effects. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

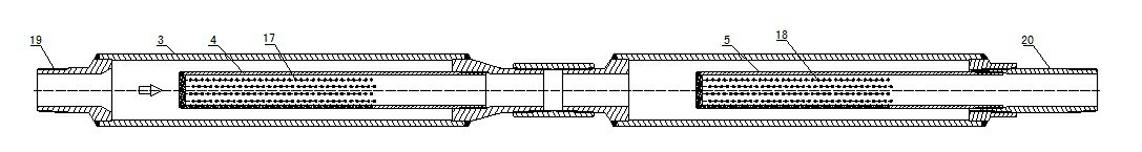

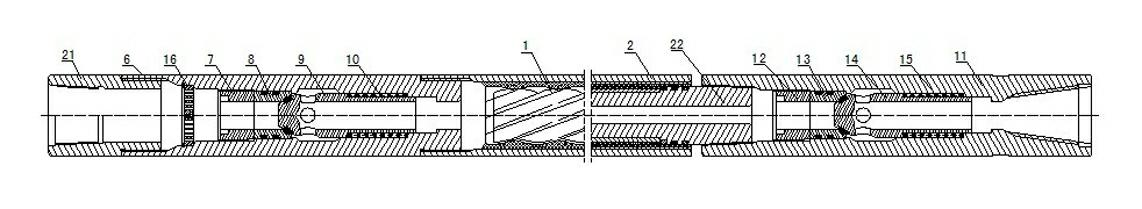

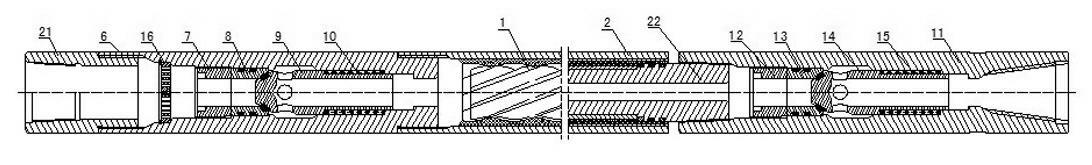

[0012] Such as figure 1 , figure 2 As shown, the non-return anti-blocking screw drilling tool includes: wellhead bipolar filter device, upper non-return anti-blocking device, hydraulic motor assembly 1, transmission shaft assembly 2 and lower non-return anti-blocking device, the wellhead bipolar The structure of the filter device includes: a casing 3, a primary filter pipe 4 and a secondary filter pipe 5 arranged in the casing 3; the structure of the upper check and block prevention device includes: an upper casing 6, a The upper positioning nut 7, the upper valve sleeve 8, the upper valve core 9 and the upper return spring 10; the structure of the lower check anti-blocking device includes: a lower housing 11, a lower positioning nut 12 arranged in the lower housing 11, a lower valve housing 13, the lower spool 14 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com