Vertical ventilating shaft explosion door capable of automatically resetting after blast release and pressure relief

An automatic reset, explosion-proof door technology, applied in mine/tunnel ventilation, door/window fittings, power control mechanisms, etc., can solve problems such as explosion-proof door damage, traction mechanism damage, quality imbalance, etc. Destructive, fast-acting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

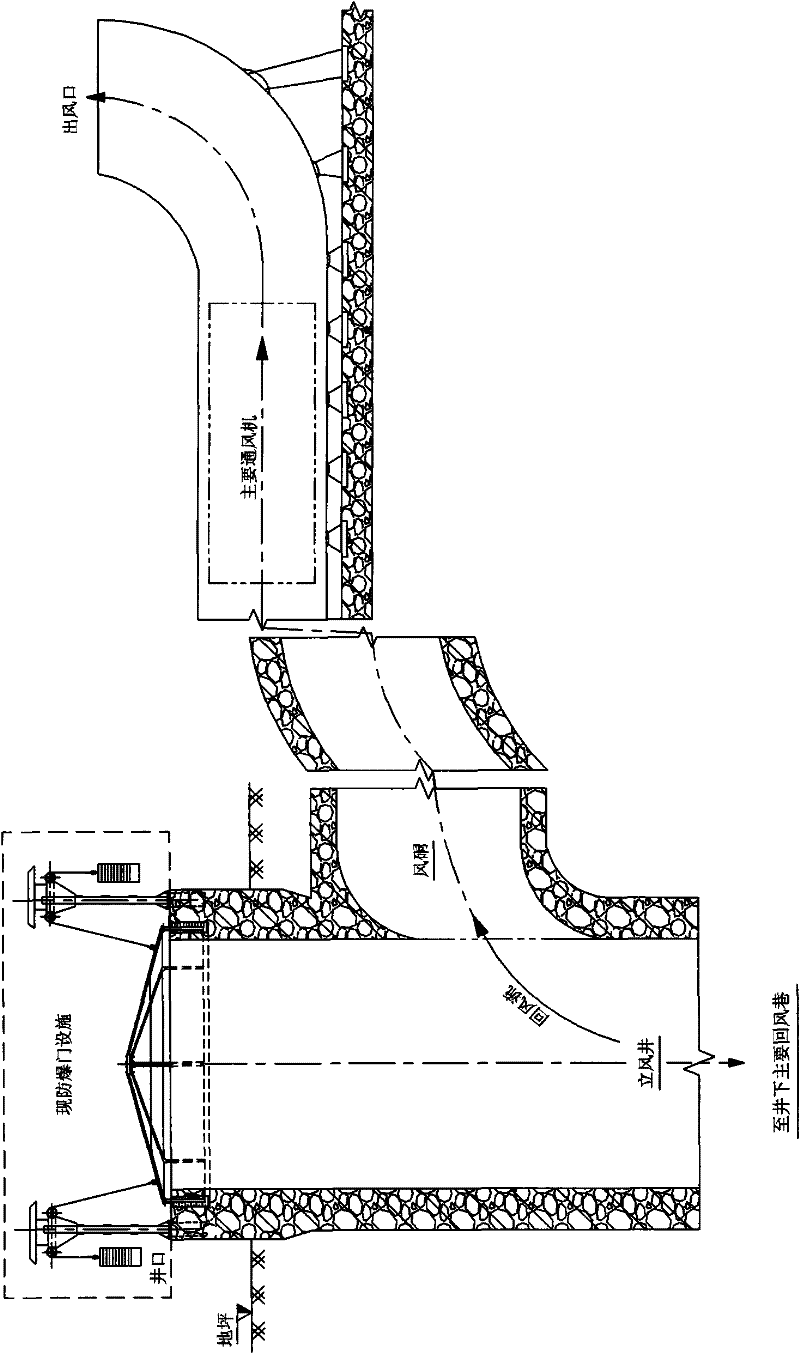

[0083] Figure 1A , Figure 1B The existing oil well 1 and oil tank 9 shown in the figure do not change the original structure and application; the heavy hammer frame 4, the heavy hammer group 5, the pulley block 6, and the traction steel rope 7 in the heavy hammer device are discarded; the anti-wind device 2 is discarded.

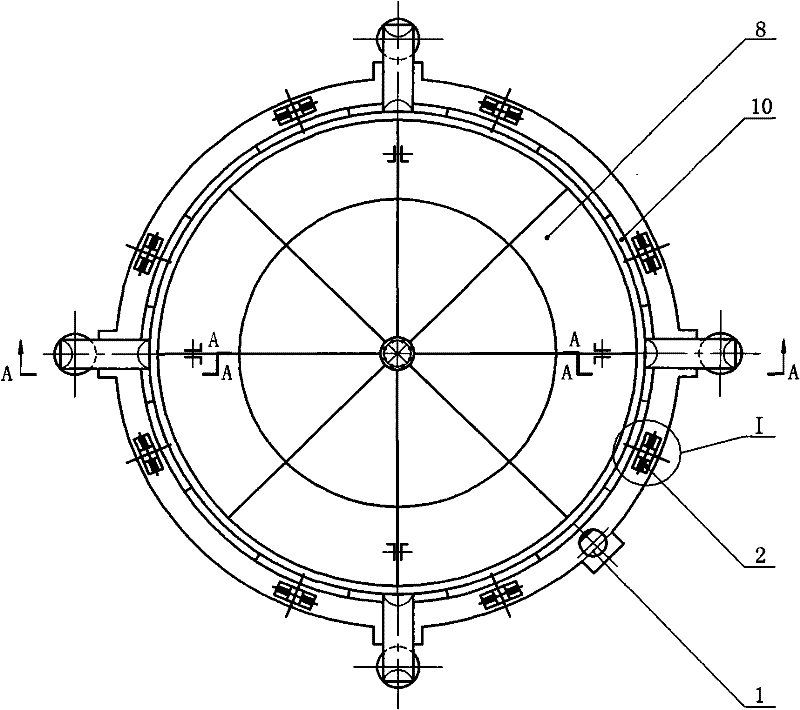

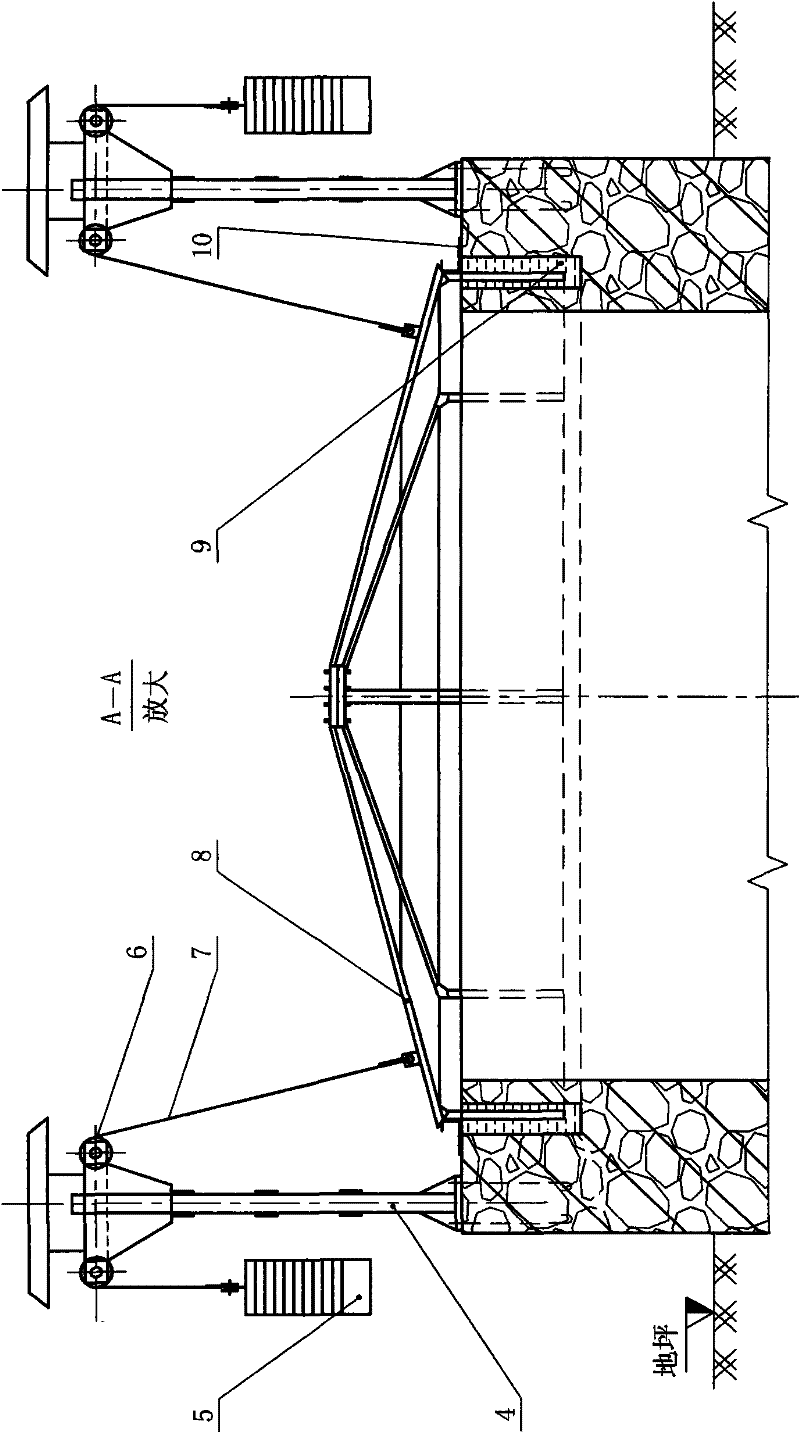

[0084] exist figure 2 , Figure 2A-Figure 2J The structure of the vertical wind shaft explosion-proof door that resets automatically after the explosion wave is released and pressure-relieving in the present invention is mainly composed of an explosion-proof door housing 8, a pilot pressure relief device 21, a diaphragm pressure relief device 15, a permanent magnet mechanism, and a door body lifting It is composed of hydraulic device and hydraulic transmission and control system.

[0085] 1. The above-mentioned explosion-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com