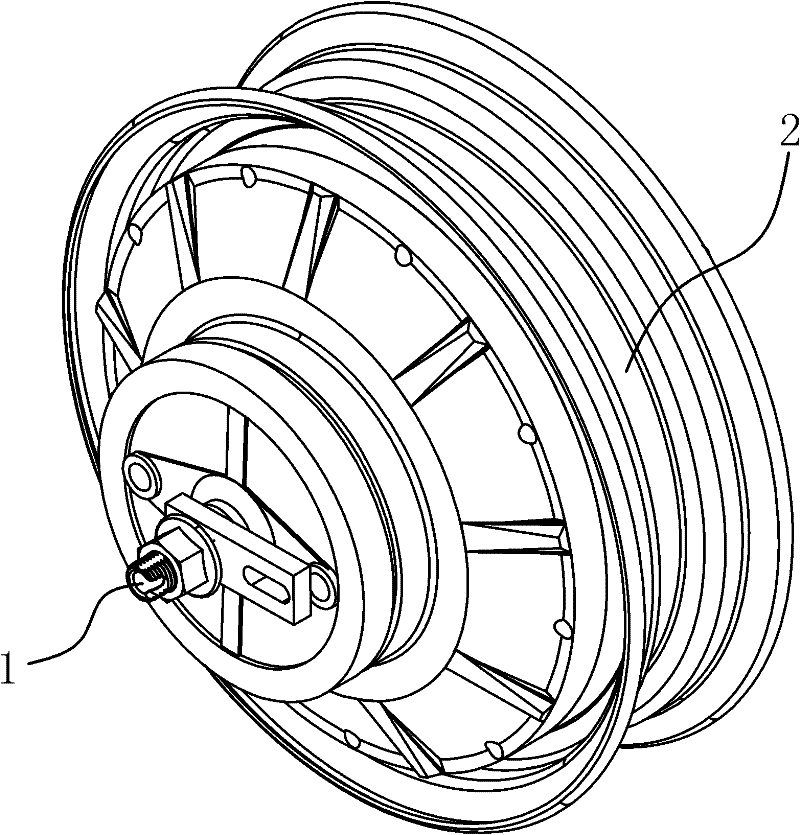

Centrifugal clutch and electric vehicle gear-shifting drive hub with same

A technology of centrifugal clutch and overrunning clutch, which is applied in the field of electric vehicles, electric vehicle shifting drive hubs, clutches, and centrifugal clutches. It can solve the problems of inability to transmit loads and engagement, etc., and achieve convenient operation, stable performance, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

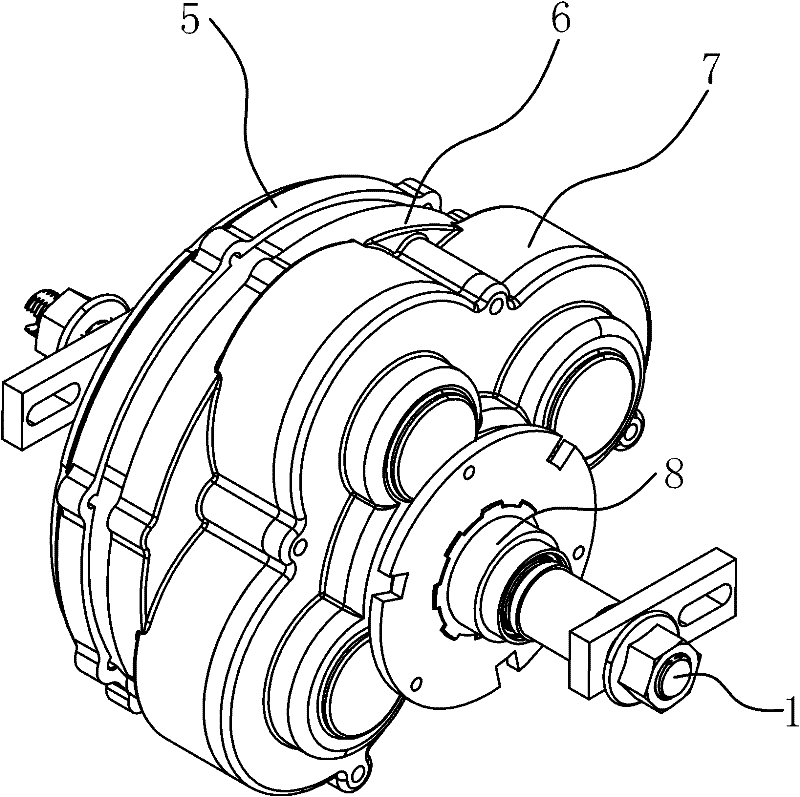

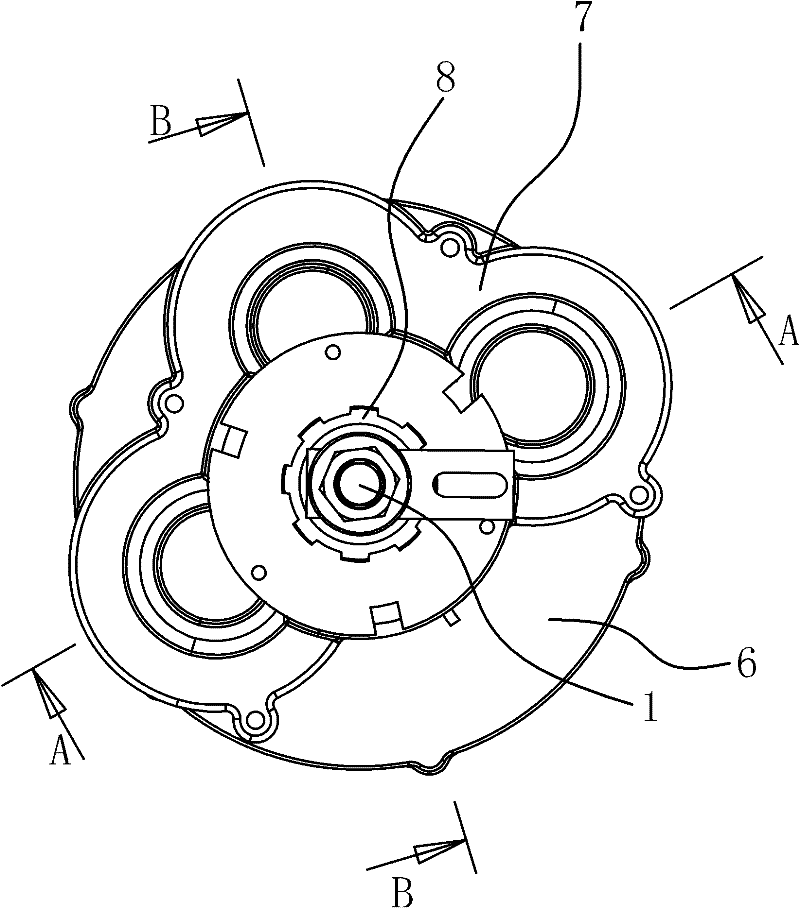

[0053] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0054] Such as Figure 7 to Figure 10 As shown, the centrifugal clutch 3 includes an input member 31, an output member 32, a ring gear 34, a pawl 36 and a reset mechanism.

[0055] Specifically, the input member 31 has a disc portion, and the output member 32 has a shaft portion. Therefore, the input member 31 can be a gear with teeth on the circumferential surface or a flywheel with a shaft portion and a disc portion; if the input member 31 is a gear, the teeth are engaged with the input device; The input device is connected. The output member 32 can be a shaft or a gear with a shaft portion. Such as Figure 7 to Figure 9 As shown, the solution provided in this embodiment is that both the input member 31 and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com