Line element

A technology of pipe fittings and fluid pipelines, applied in the field of pipe fittings, can solve the problems of pipeline fluid solidification, failure to maintain heating, failure to prevent solidification, etc., and achieve the effect of reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The particulars presented here are exemplary and used for illustrative discussion of embodiments of the invention only, and are presented to provide what is believed to be the most useful and understandable description of the principles and conceptual aspects of the invention. Regarding this point, there is no attempt to introduce the structural details of the present invention beyond the level required for a basic understanding of the present invention. Those skilled in the art can clearly understand how to implement the present invention in practice through the description and accompanying drawings. Several forms.

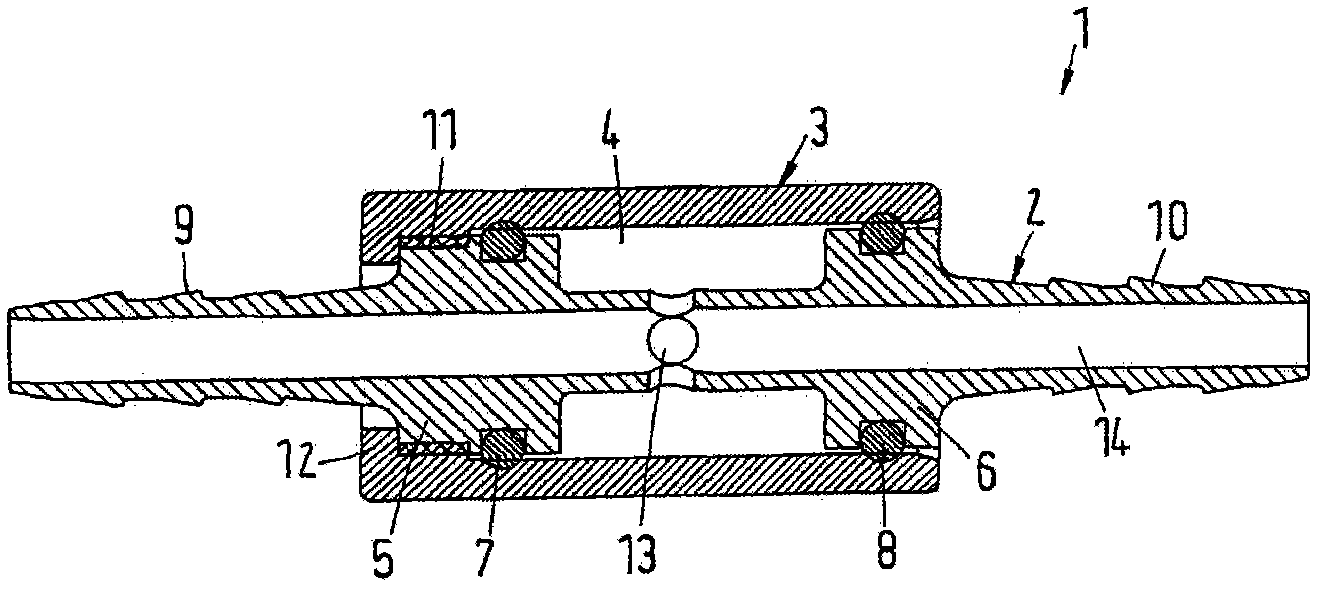

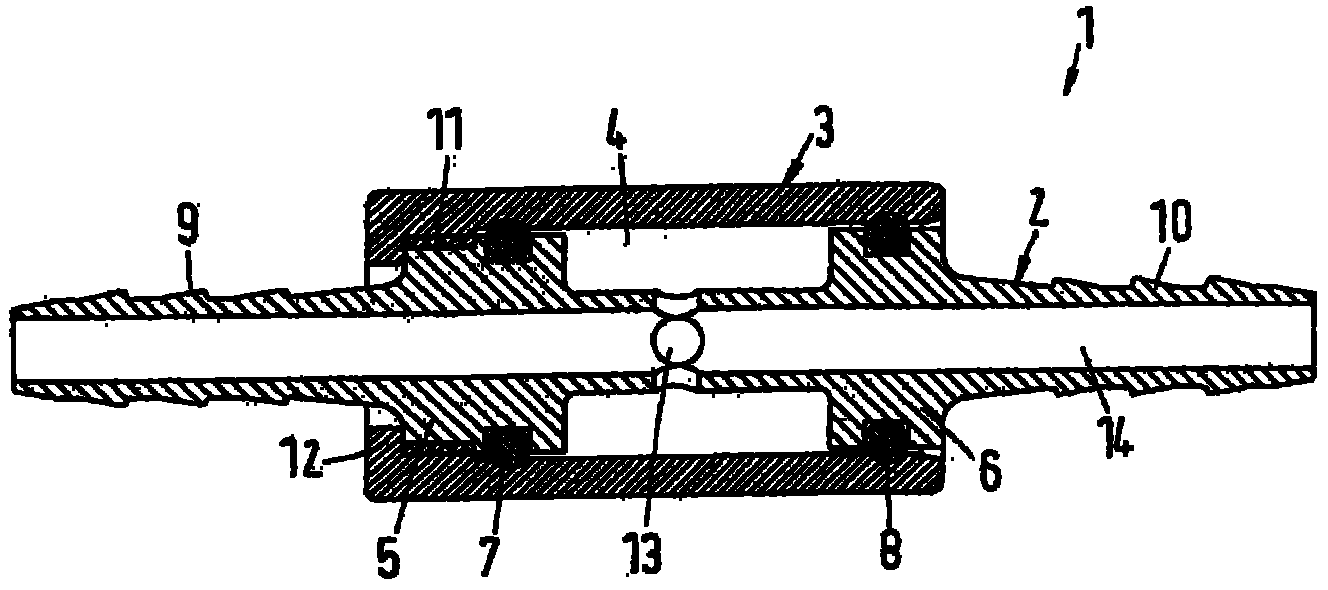

[0035] exist figure 1 A pipe fitting 1 with a fluid line 2 is shown in . The housing 3 surrounds the fluid line 2 in an annular manner, and an annular space 4 is implemented or formed between the housing 3 and the fluid line 2 . The annular space 4 is axially delimited by respective annular flanges 5 , 6 . The ring flanges 5 , 6 are integral with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com