Clamp device of two-shaft synchronous vibration table

A technology of synchronous vibration and fixture device, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc., to achieve the effect of preventing damage, high reliability and large allowable load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

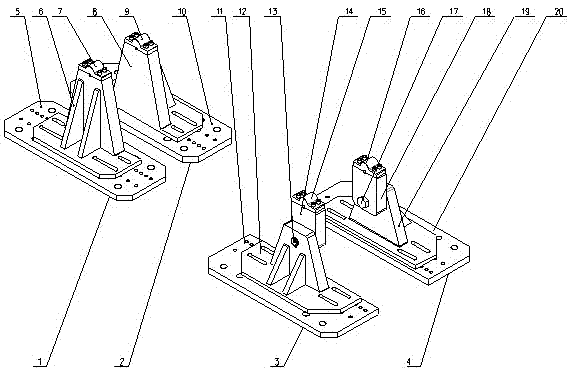

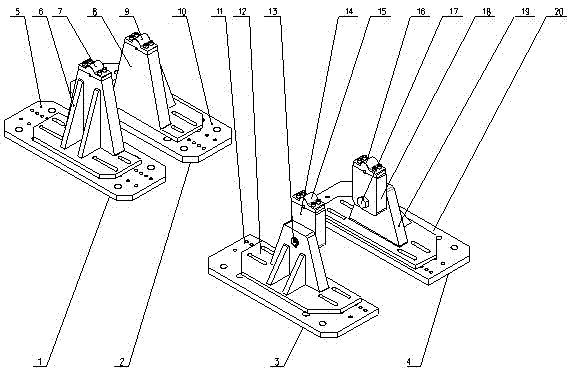

[0010] Such as figure 1 As shown, the two-axis synchronous vibrating table fixture device includes a front adjustment fixture and a rear adjustment fixture, and the front adjustment fixture includes two parallel front adjustment clamping blocks, the first front adjustment clamping block 1, and the second front adjustment clamping block 2. The rear adjustment fixture includes two parallel rear adjustment clamping blocks, the first rear adjustment clamping block 3 and the second rear adjustment clamping block 4; the first front adjustment clamping block 1 includes the first front adjustment clamping block Plate 5, the first front adjustment bottom block 6, the first front adjustment pressure block 7, the second front adjustment clamping block 2 includes the second front adjustment bottom block 8, the second front adjustment pressure block 9, the second front adjustment plate 10, the first rear adjustment clamping block 3 includes a first rear adjustment plate 11, a first rear ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com