Experiment device for testing fatigue life of threading connector of petroleum drill

A threaded joint and fatigue life technology is applied in the field of experimental devices for testing the fatigue life of full-size oil drilling tool threaded joints, and can solve the problem of not being able to test the fatigue life of full-scale drilling tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

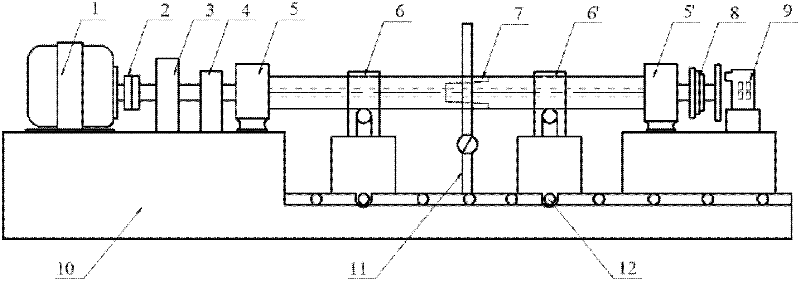

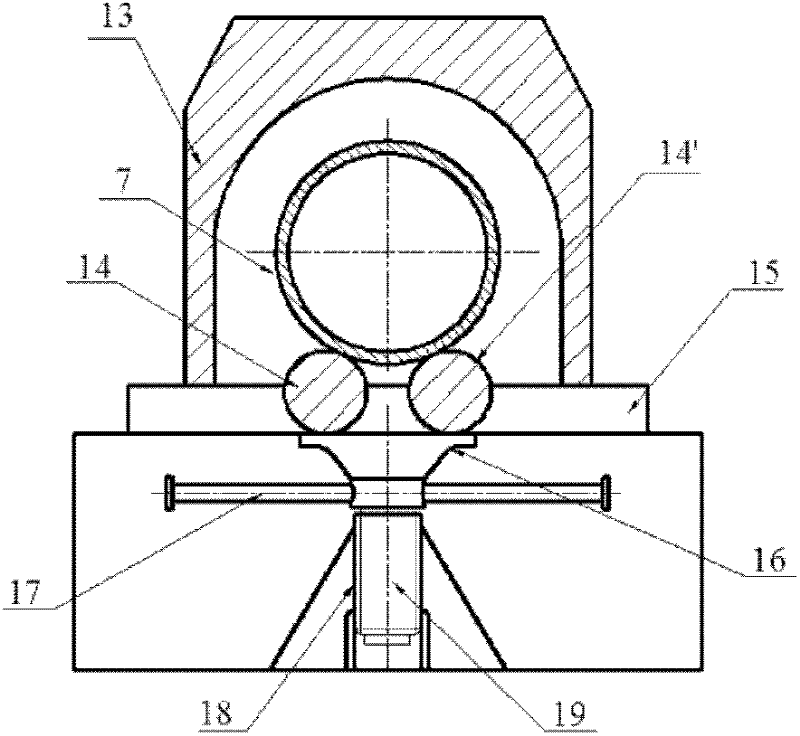

[0015] see figure 1 , the present invention includes: base 10, guide rail 12, motor 1, coupling 2, floating bearing 3, spherical roller bearing 4, fixed end spring clamps 5 and 5', bending moment applying devices 6 and 6', deflection measurement Instrument 11, tailstock 8, counter 9. Install the motor 1 at one end of the base 10; the motor 1 is connected with the coupling 2; the coupling 2 is sequentially connected with the floating bearing 3 and the spherical roller bearing 4; the fixed end of the head is set at one end of the spherical roller bearing 4 Spring clamp 5; Tailstock 8 is placed on the other end of the base 10, and the tail fixed end spring clamp 5' is connected with the tailstock 8; two fixed end spring clamps 5, 5' at the head and tail respectively fix the two ends of the drilling tool sample 7 And apply torque; the bending moment app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com