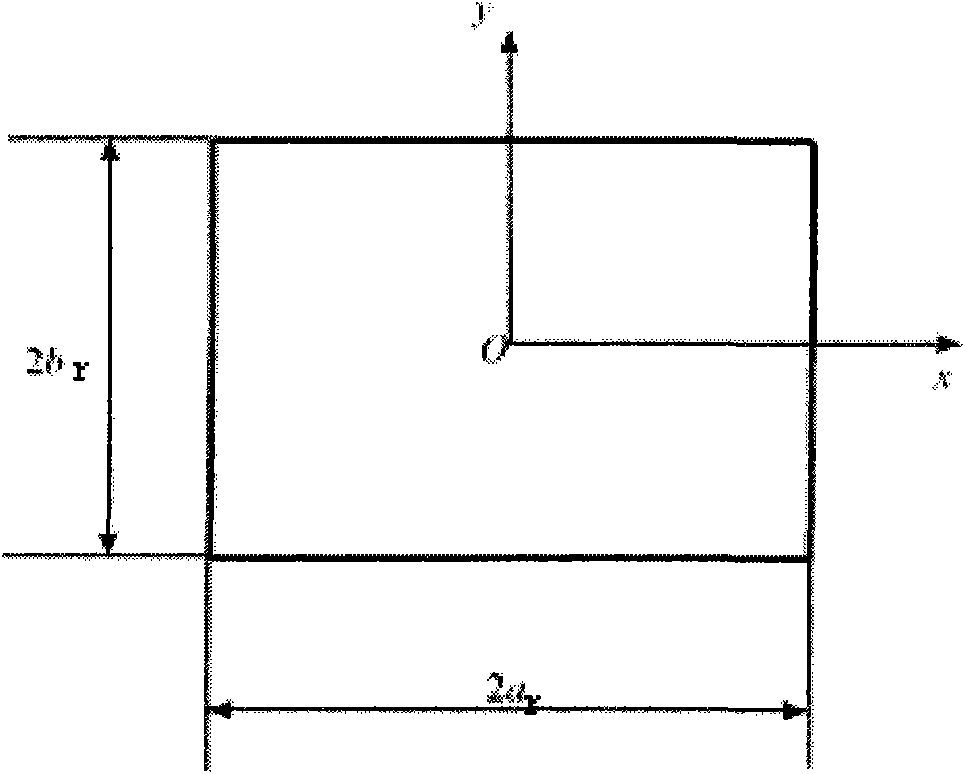

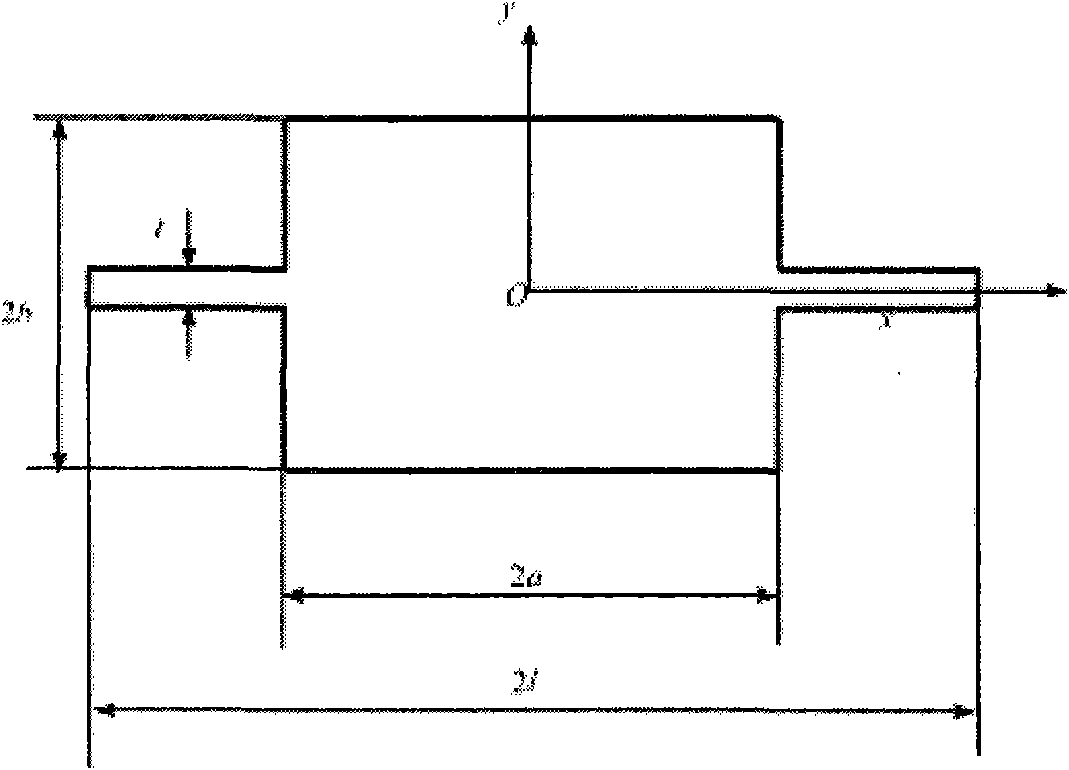

Method for determining sectional dimension of rectangular beam with lugs

A technology of cross-section size and rectangular beam, which is applied to the determination of the cross-section size of rectangular beams, can solve the problems such as the accuracy affecting the stiffness of the model section, the large error of dimensional data, and the long time, so as to shorten the time for determining the cross-section size and improve the design efficiency. , the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

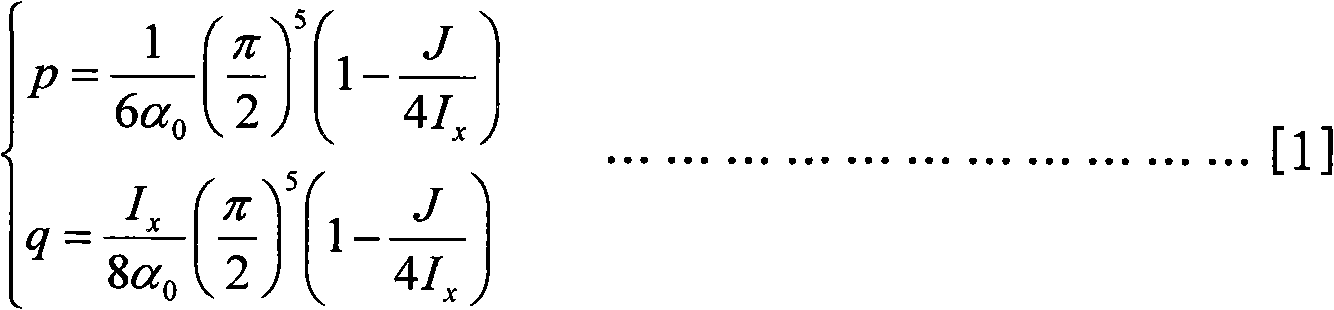

Method used

Image

Examples

Embodiment

[0057] The method of the present invention is verified by calculation.

[0058] Three sets of cross-sections are given, and the cross-sections P1 to P3 are Example 1 to Example 3, respectively. Table 1 gives the predetermined values, ie target values, of the geometrical properties of the three embodiments. For P1, let t=2.0mm, and for P2 and P3, let t=1.0mm, and design the cross-sectional dimension. Table 1 also gives the geometrical properties of the design section obtained using the method of the present invention, that is, the design value, and the error of the design value. Table 2 gives the dimensional design values for the three examples.

[0059] The design values of the section geometric characteristics in Table 1 are calculated according to the corresponding section dimensions in Table 2 by FEMAPv9.31. Compared with the target value, the error of the design section characteristic value is not more than 2%. From an engineering point of view, this is a high-preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com