Method for detecting scratch defects of printing product

A technology of defect detection and printed matter, applied in the field of image processing, to achieve the effect of high detection efficiency and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific embodiments.

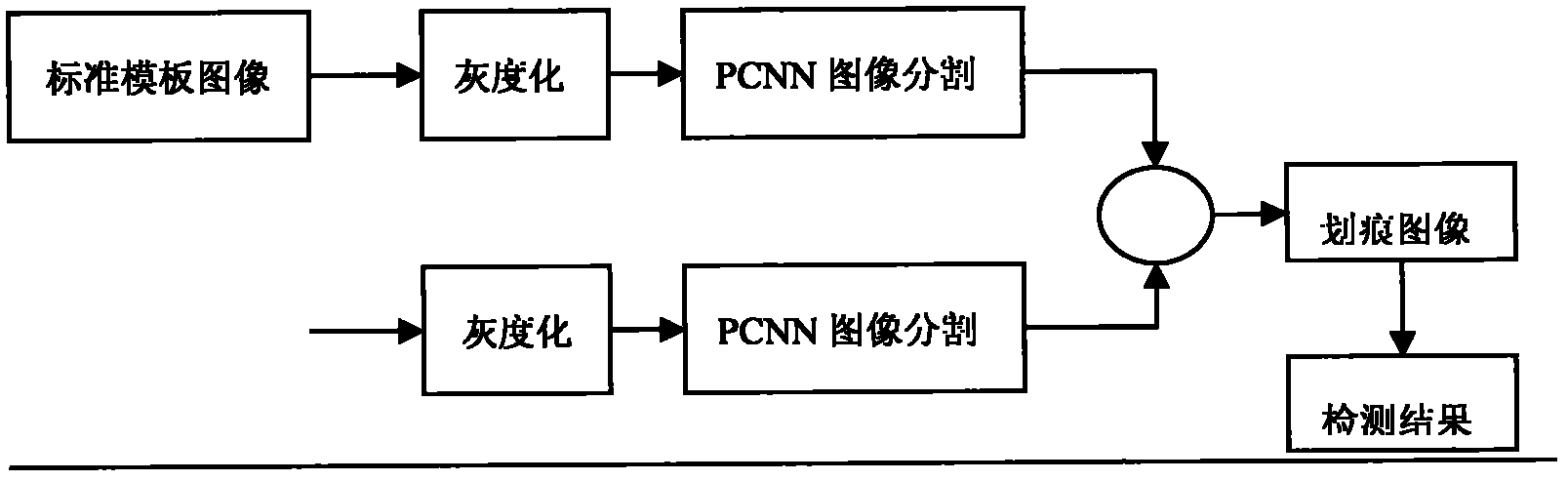

[0052] refer to figure 2 , image 3 As shown, the embodiment of the present invention performs an initialization operation in advance, that is, collects an image to be grayed out, and then uses the PCNN method to segment the image.

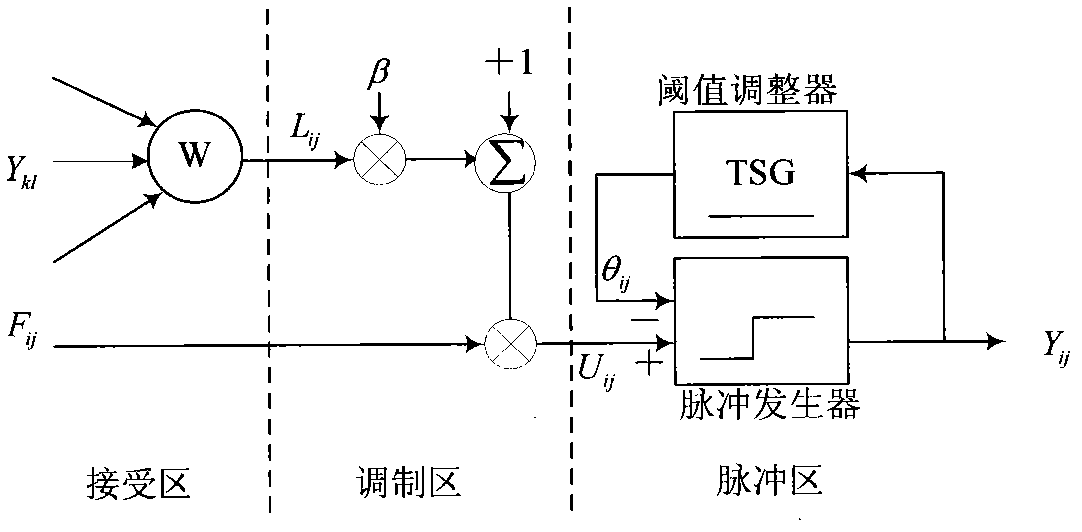

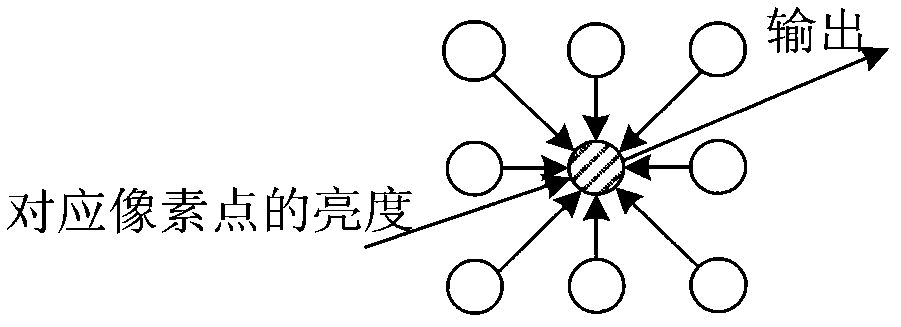

[0053] Pulse coupled neural network (PCNN) is a feedback network composed of several neurons interconnected, each neuron

[0054] Including three parts: acceptance area, modulation area and pulse area. The receptive area accepts input from external stimuli and other neurons: where F ij is the feedback input of the neuron; S ij Input signal for the stimulus (such as the gray value of the image); L ij is the input of other neurons connected to the neuron under the synaptic connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com