Modular manufacture training unit device and modular combined manufacture training system

A technology of modular units and training systems, applied in teaching models, educational tools, instruments, etc., can solve problems such as poor hands-on ability, students' inability to fully participate, and inability to implement arbitrary combinations, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

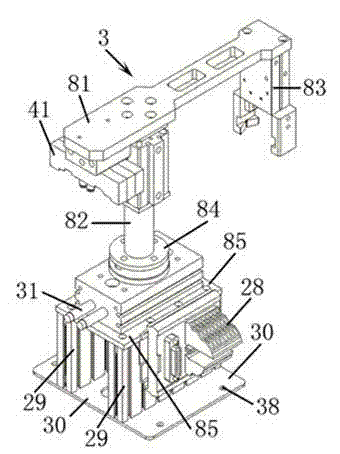

[0416] The modular manufacturing training unit device is composed of a training module unit and a combined installation training platform (12). The training module unit is composed of a processing / assembly module unit (1), a linear walking manipulator module unit (2), a fixed manipulator module unit (3), three-dimensional warehouse module unit (4), cargo platform module unit (5), conveyor belt detection module unit (6), inclined slideway module unit (7), horizontal slideway module unit (8), well type supply Material module unit (9), motor module unit (10), multi-piece processing / assembly module unit (11), terminal block and combined installation training platform (12), the training module units are independently assembled and operated for training, each The modular units for training are installed on the combined installation training platform (12) after assembly, and the modular units for training are respectively combined to form a modularized combined manufacturing training ...

Embodiment 2

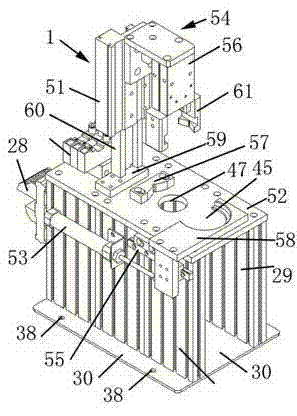

[0418]The processing / assembly module unit (1) consists of a retaining plate (52), a retrieving and positioning cylinder (53), a processing / assembling manipulator (54), a guide rail (55), a positioning block (57), and a retrieving and positioning block (58) , lifting cylinder (51), clamping cylinder (56), base (59), lifting column (60), mechanical clamp (61), terminal block (28), profile base (29), fixed base plate (30) and The electromagnetic valve group (41) is composed of a profile matrix (29) opposite to the edge of both sides of the lower fixed base plate (30) of the processing / assembly module set (1), the fixed base plate (30) is generally rectangular, and the profile base (29 ) is provided with a retaining plate (52) on the upper part, fixed positioning holes (38) are provided on both side edges of the fixed bottom plate (30), and the distance between the fixed positioning holes (38) is the same as that on the combined installation training platform (12) The reference in...

Embodiment 3

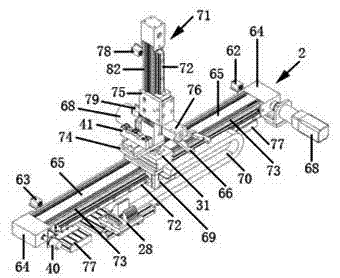

[0420] The linear walking manipulator module unit (2) is composed of a right limit terminal group (62), a left limit terminal group (63), a driven bearing block (64), a transmission support frame (65), and a motor for performing displacement (68) , cable drag chain (70), manipulator (71), translational chassis (69), support column (82), guide rail of lifting manipulator (72), upper limit terminal group (78), lower limit terminal group (79), Motor (68), Y-type reclaiming manipulator (66), solenoid valve (41), rotating chassis (74), reclaiming manipulator bracket (75), rotating cylinder (31), guide rail (72), conveyor belt for executing the lifting manipulator (73), terminal block (28) and rotary encoder (40). The two ends of the transmission support frame (65) are provided with driven bearing blocks (64), and the driven bearing blocks (64) at one end of the transmission support frame (65) are provided with a rotary encoder (40), and the rotary encoder (40 ) is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com