Blasting apparatus and method for blasting

A shot peening device and a technology for processed objects, which are applied in the direction of explosion generating devices, metal processing equipment, used abrasive processing devices, etc., can solve problems such as deterioration of the working environment and damage to the health of operators, and achieve the effect of maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the shot blasting apparatus and the shot blasting method of the present invention will be described in detail with reference to the drawings.

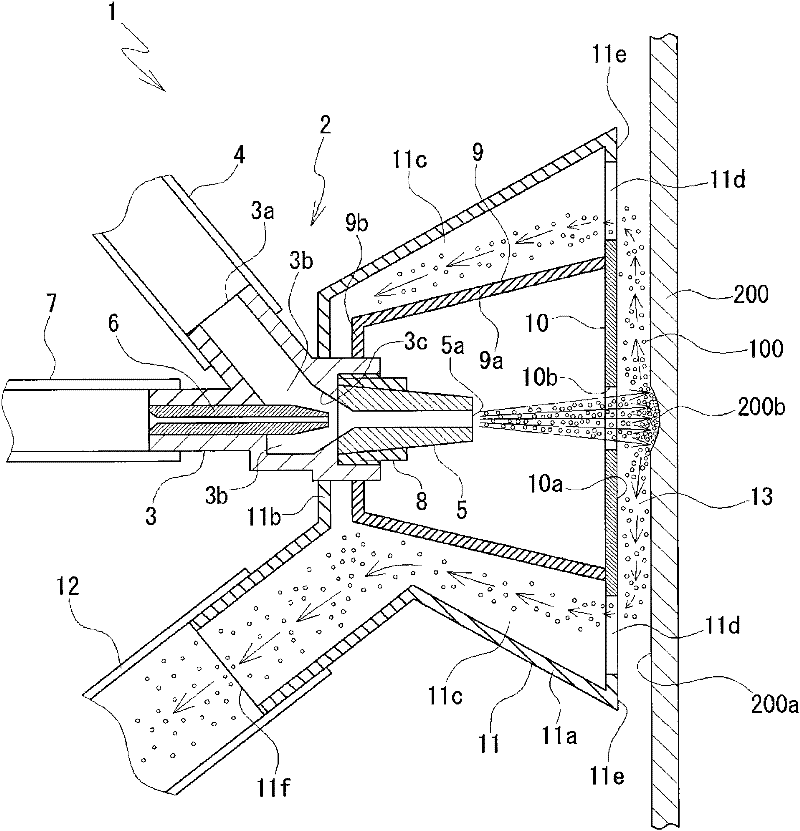

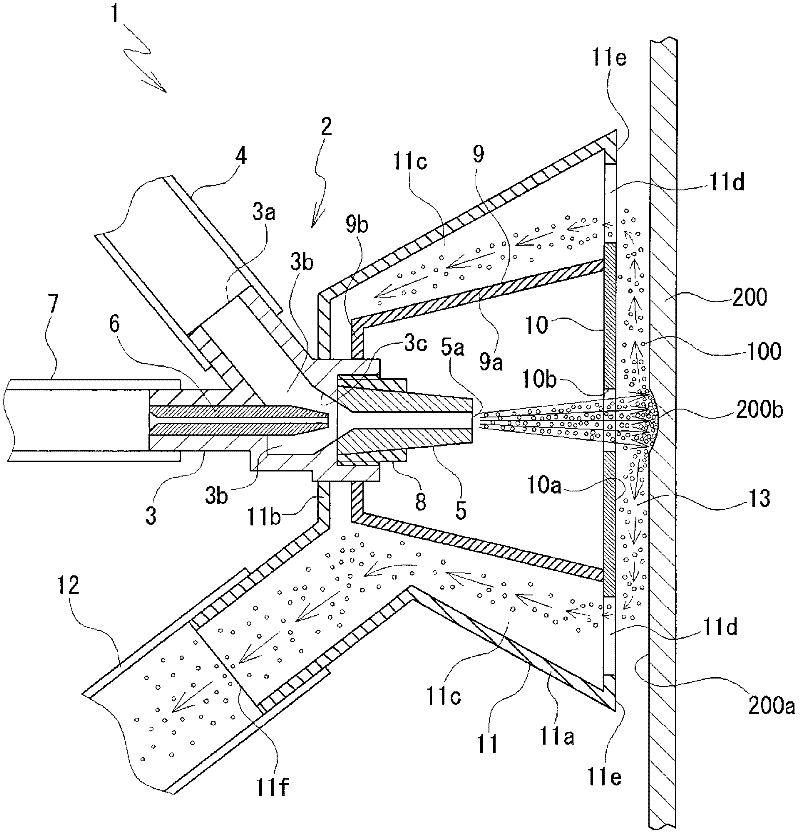

[0031] figure 1 It is a sectional view which shows the schematic structure of the shot blasting apparatus 1 of this invention. As shown in the figure, in the injection nozzle 2 that the shot blasting device 1 is equipped with, a substantially cylindrical container-shaped abrasive guide chamber 3b is formed in the nozzle body 3. The tank communicates with the abrasive inlet 3 a through the abrasive supply hose 4 to guide the abrasive 100 . A conical inner surface 3 c deep-drawn into a conical shape is formed at the front end portion of the abrasive guide chamber 3 b.

[0032] Moreover, the front-end|tip part of the air injection pipe 6 inserted from the rear of the abrasive guide chamber 3b is arrange|positioned inside the conical inner surface 3c. The air injection pipe 6 communicates with a compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com