Lower structure of vehicle

A vehicle and bending technology, which is applied in the field of vehicle substructure, can solve the problems of increasing the front bending stiffness of the front longitudinal beam, increasing the number of components, and increasing the stiffness, so as to improve the buckling strength, enhance the bending stiffness, and strengthen the The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. Note that in the description of the drawings, the same reference numerals denote similar components and repeated descriptions are omitted. In addition, for the convenience of illustration, the dimensional ratios of the drawings do not always coincide with those in the description.

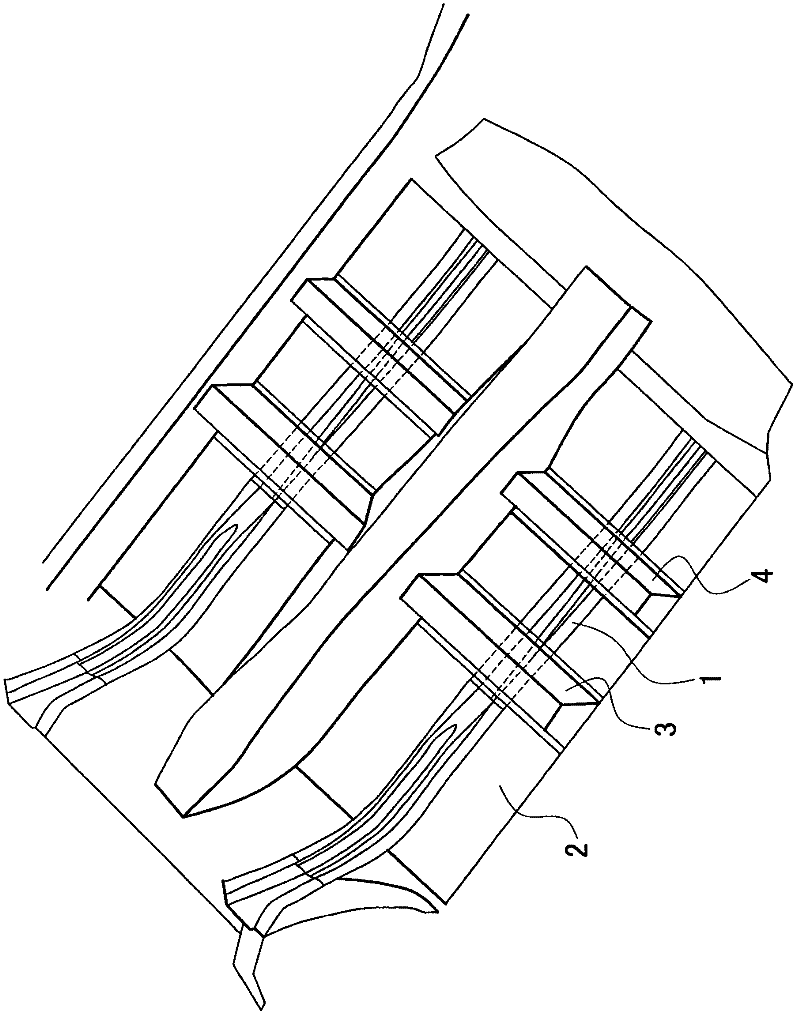

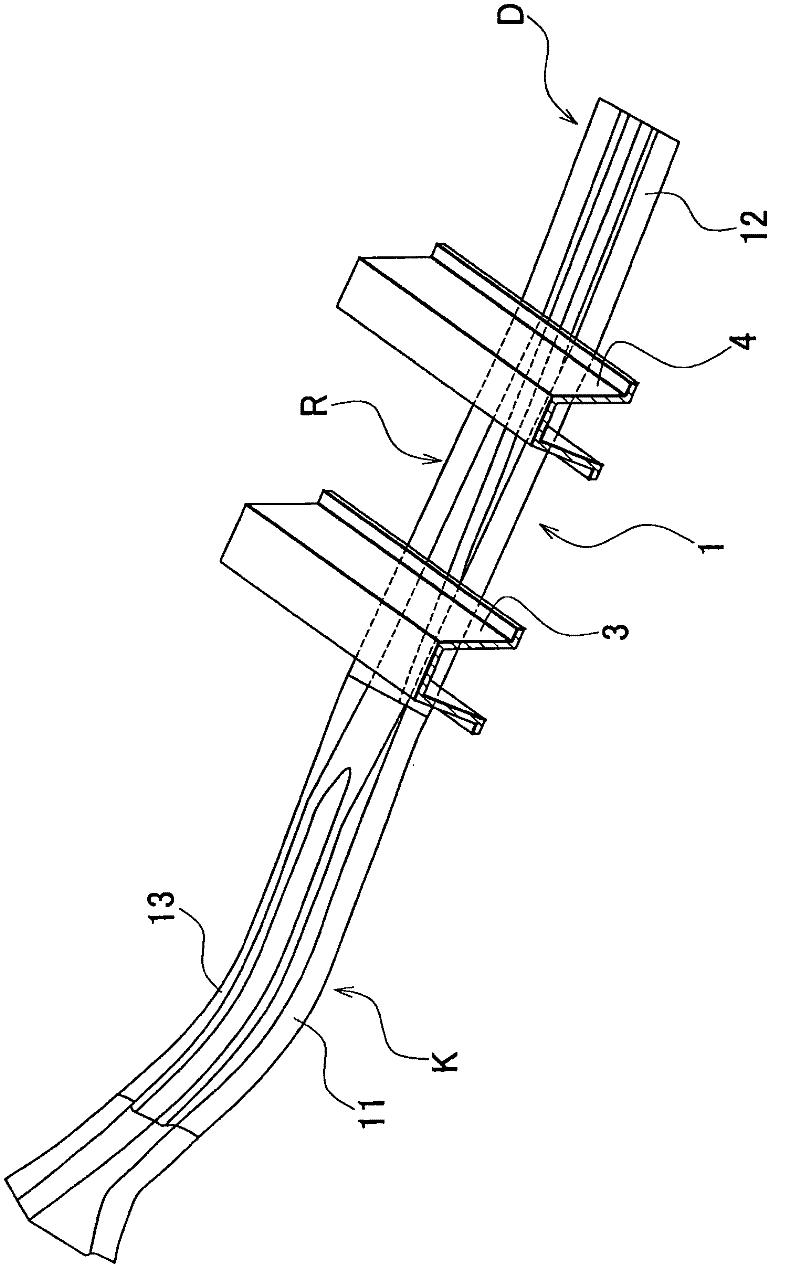

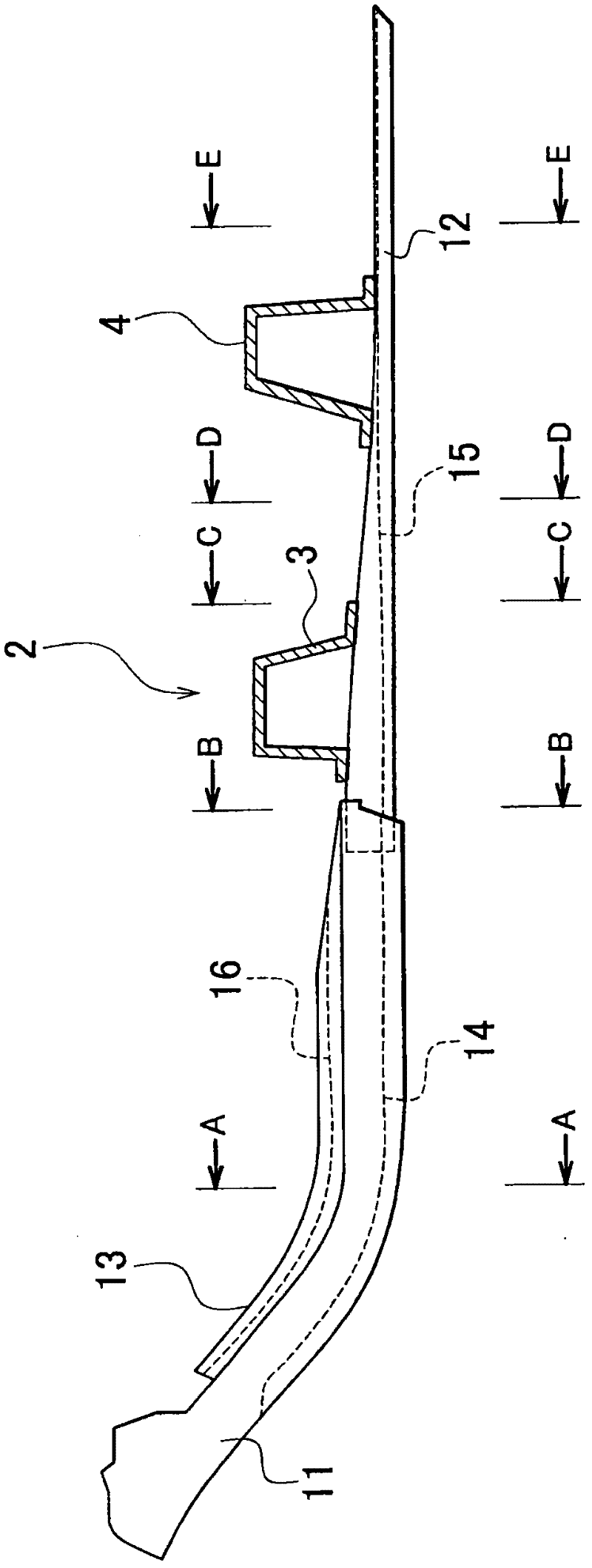

[0062] figure 1 is a perspective view of the lower structure of the vehicle according to the present embodiment. figure 2 is a perspective view of the floor component. image 3 is a side view of a floor member in the substructure of the vehicle. Figure 4A is along image 3 A cross-sectional view taken along line A-A in . Figure 4B is along image 3 A cross-sectional view taken along line B-B in . Figure 4C is along image 3 A cross-sectional view taken along line C-C in . Figure 4D is along image 3 A cross-sectional view taken along line D-D in . Figure 4E is alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com