Method for manufacturing a solution of diacid/diamine salts

A diacid and solution technology, which is applied in the directions of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems such as the production capacity of polymerization equipment, product quality solution storage and transportation problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

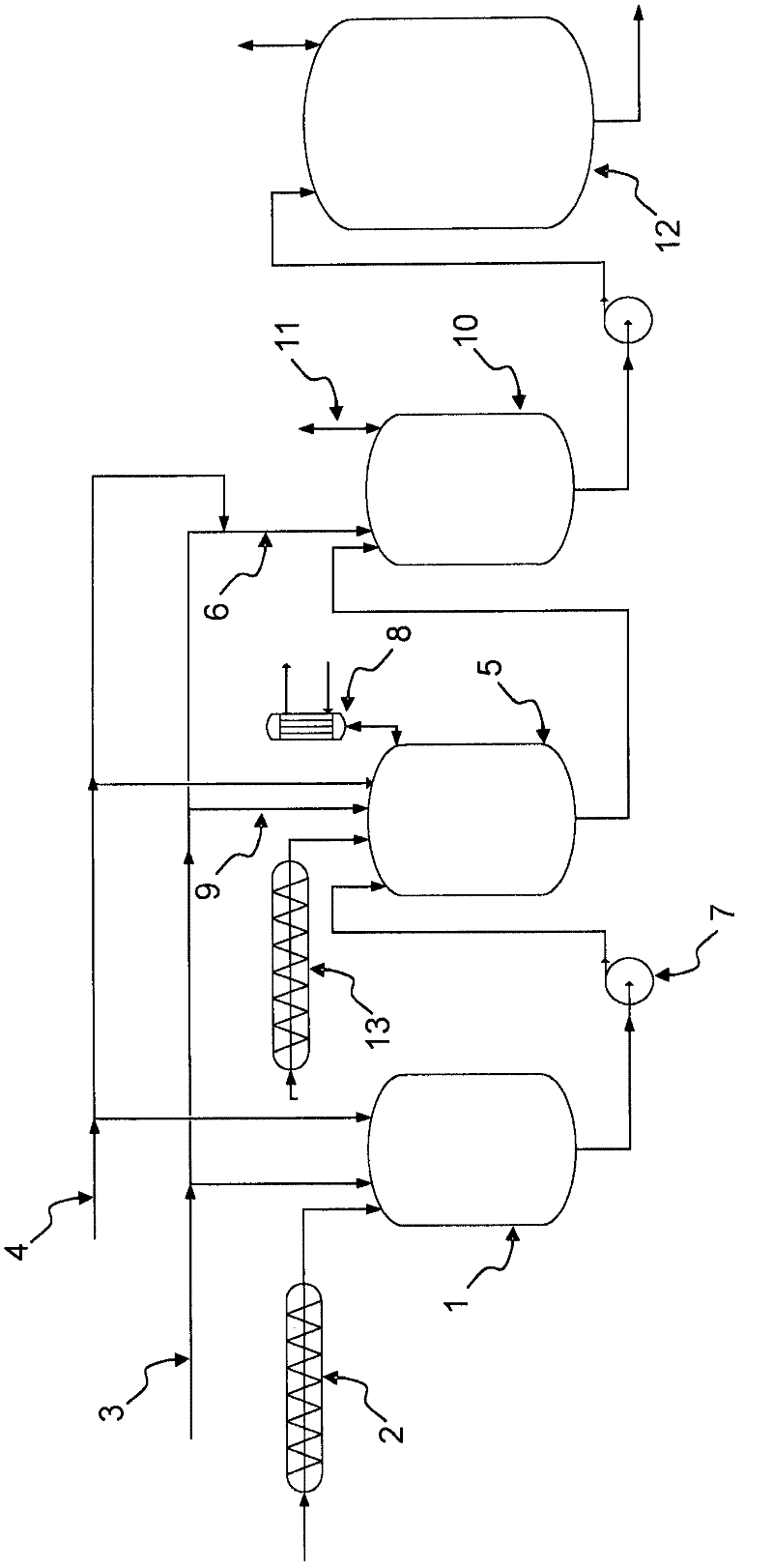

[0058] Reference attached figure 1 A first embodiment of the method of the invention operating according to the batch mode will now be described. The plant comprises a first stirred reactor 1 to which a liquid stream 3 of adipic acid 2 and hexamethylenediamine, usually in powder form, is added. Water 4 is also introduced into the reactor.

[0059] In Reactor 1, which contains a small amount of adipic acid-rich aqueous solution of adipic acid and hexamethylenediamine, called raffinate, various substances are added. This aqueous solution is advantageously a small fraction of the solution prepared in the previous operation, and it advantageously has substantially the final composition of the solution to be prepared in Reactor 1, i.e., a diacid / diamine molar ratio equal to about 2.4, The weight concentration of the dissolved material is about 57%.

[0060] The plant also comprises a second stirred reactor 5, into which water 4, a stream 9 of hexamethylenediamine and terephthali...

no. 1 approach

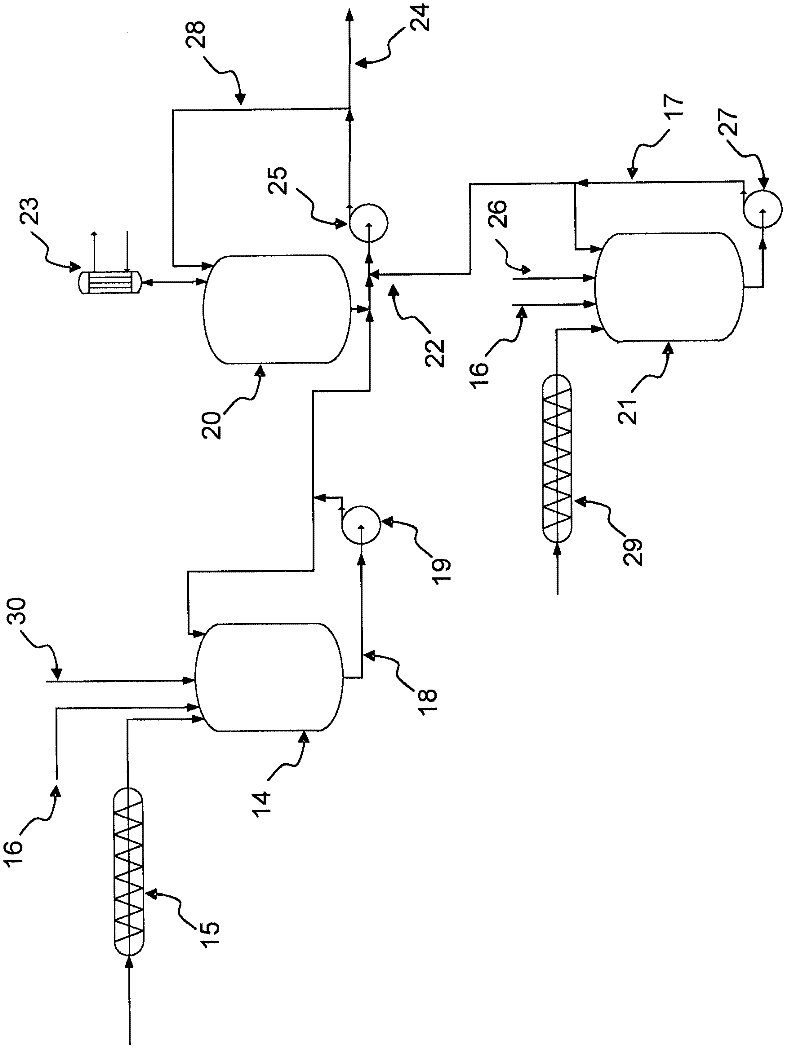

[0069] As in the first embodiment, the method includes the step of dissolving terephthalic acid in the reactor 21 . Terephthalic acid via a worm system 29 is supplied simultaneously with water 16 and diamine 26 either neat or in aqueous solution to obtain in reactor 21 a material comprising a diacid / diamine molar ratio of less than 1, for example about 0.48 and dissolved The concentration is, for example, equal to a 49% by weight solution.

[0070] An external circulation loop 17 comprising a pump 27 to obtain homogenization of the solution in the reactor 21 is shown. Reactor 21 is also equipped with a mechanical stirrer (not shown). A portion 22 of the solution circulated in the loop is supplied to the reactor 20 .

[0071] The reactor 20 is equipped with an external neutralization circuit 28 comprising a pump 25 .

[0072] As in the first embodiment, the heat released by the neutralization reaction can raise the temperature of the solution up to the boiling point of the s...

Embodiment 1

[0077] Example 1 : A 52% by weight aqueous solution of 66 / 6T 66 / 34 (molar ratio) salt is produced according to a batch process.

[0078] Preparation of solution (A')

[0079] An aqueous solution of terephthalic acid and hexamethylenediamine was prepared by adding terephthalic acid (11.2 kg) to a liquid having a temperature equal to 80° C. and demineralized water (27.4 kg) were added to reactor 5; this reactor contained 22 kg of the residue of an aqueous solution of terephthalic acid, adipic acid (34 / 66 in molar ratio) and hexamethylenediamine, which was obtained at 103 The diacid / diamine molar ratio = 1.017 at °C shows a concentration by weight of dissolved material of about 52%.

[0080] Advantageously, this solution residue is a fraction of the solution (A) obtained in reactor 5 in the previous preparation operation.

[0081] The time for adding terephthalic acid is approximately equal to 4 minutes, and its salt formation with hexamethylenediamine leads to an increase in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com