Gas discharge system for a refrigeration compressor and a refrigeration compressor

A refrigeration compressor and gas discharge technology, which is applied in the field of compressors, can solve problems such as power loss, and achieve the effects of reducing power loss, reducing heat exchange, and reducing pressure transients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

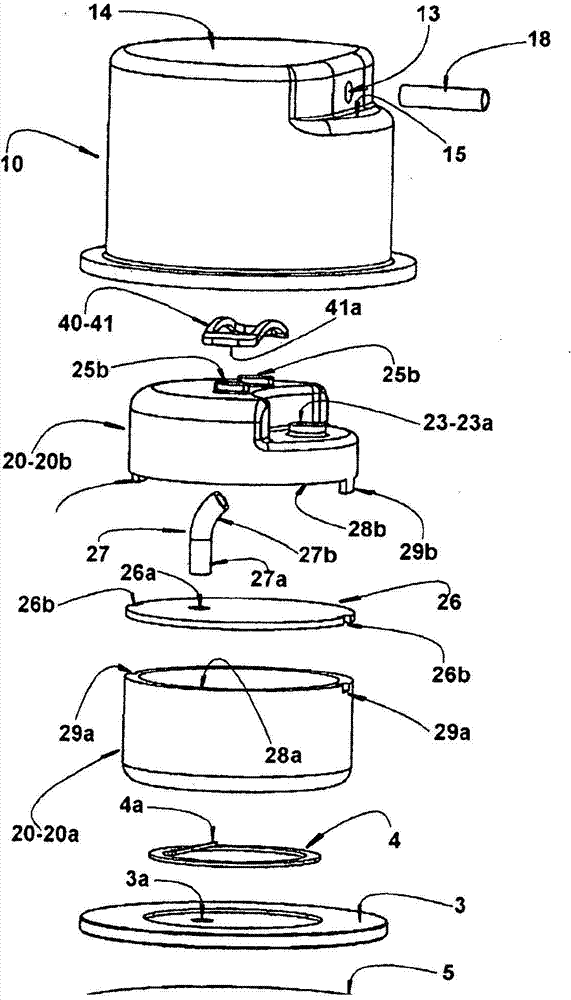

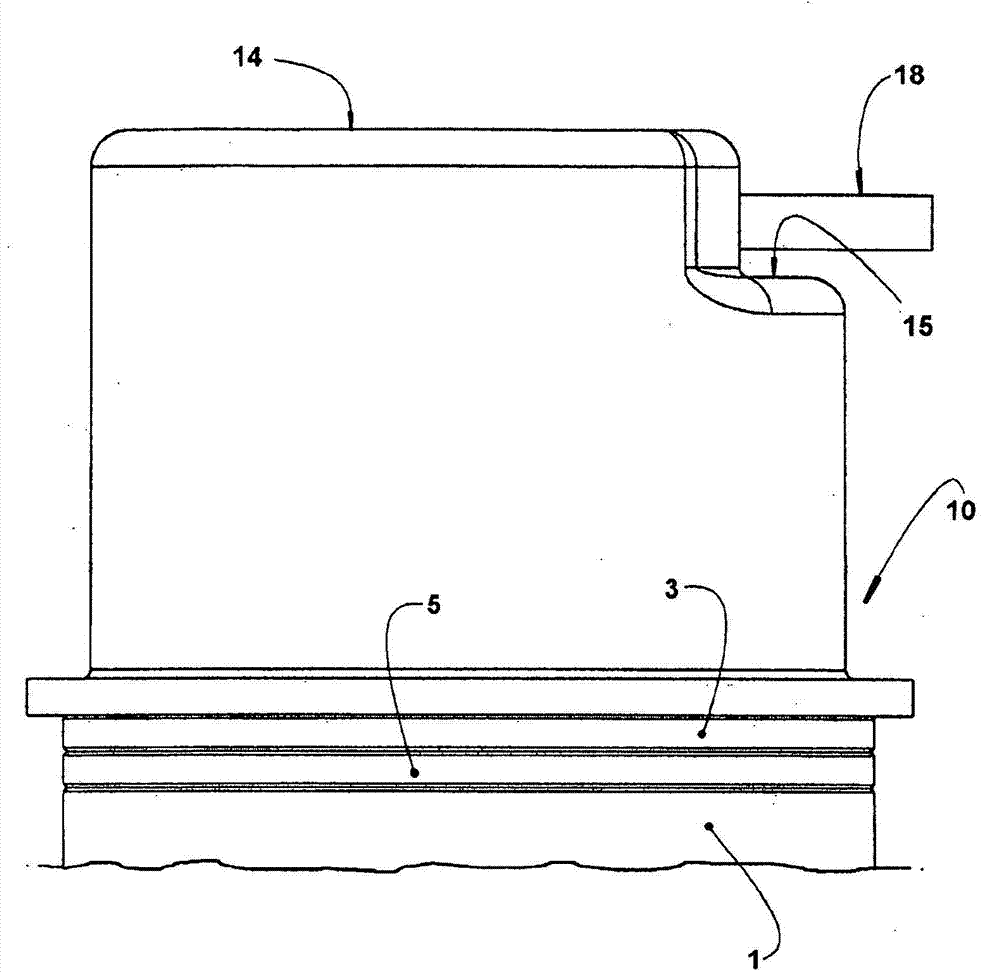

[0018] The present invention will describe a hermetic reciprocating type refrigeration compressor, and said refrigeration compressor includes a motor-compressor assembly (not shown), said refrigeration compressor includes a cylinder crankcase 1 (in Figure 4 Partially shown in ), the cylinder crankcase defines a cylinder 2 inside which a piston is axially displaced by the action of a rotary or linear electric motor (not shown).

[0019] The cylinder crankcase may be constructed from any suitable metal alloy known in the art.

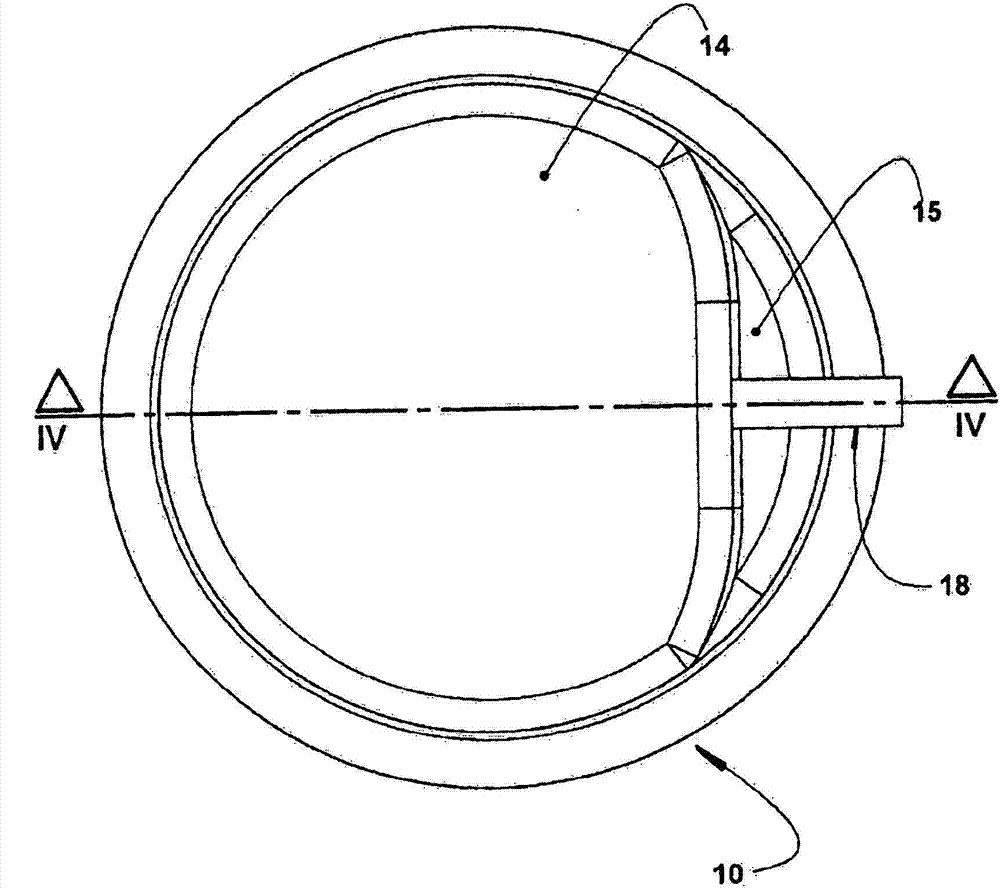

[0020] The cylinder 2 has an open end through which the piston is received, and an opposite end closed by the valve plate 3 (at Figure 4 is shown in ), against which valve plate 3 delimits a compression chamber C with the cylinder 2 is seated a generally metallic cylinder head 10 . The valve plate 3 is constructed of a metal alloy so as to operate with at least one suction valve (not shown), facing the interior of the cylinder 2, and at least one disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com