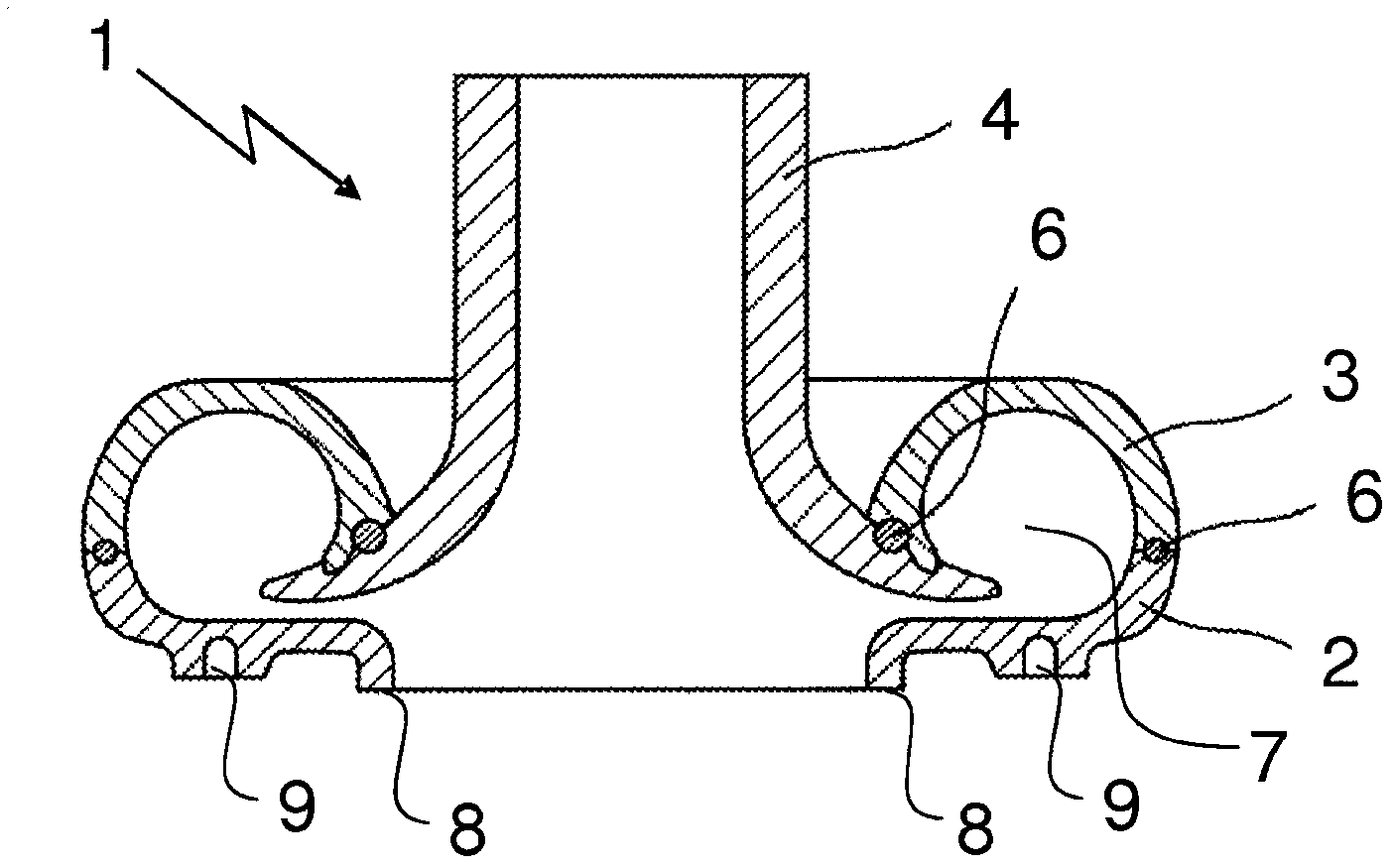

Plastic housing of radial flow compressor

A compressor and radial flow technology, which is applied in the field of radial compressor shells, can solve the problems of increasing manufacturing complexity and achieve the effect of light weight, high size and good durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

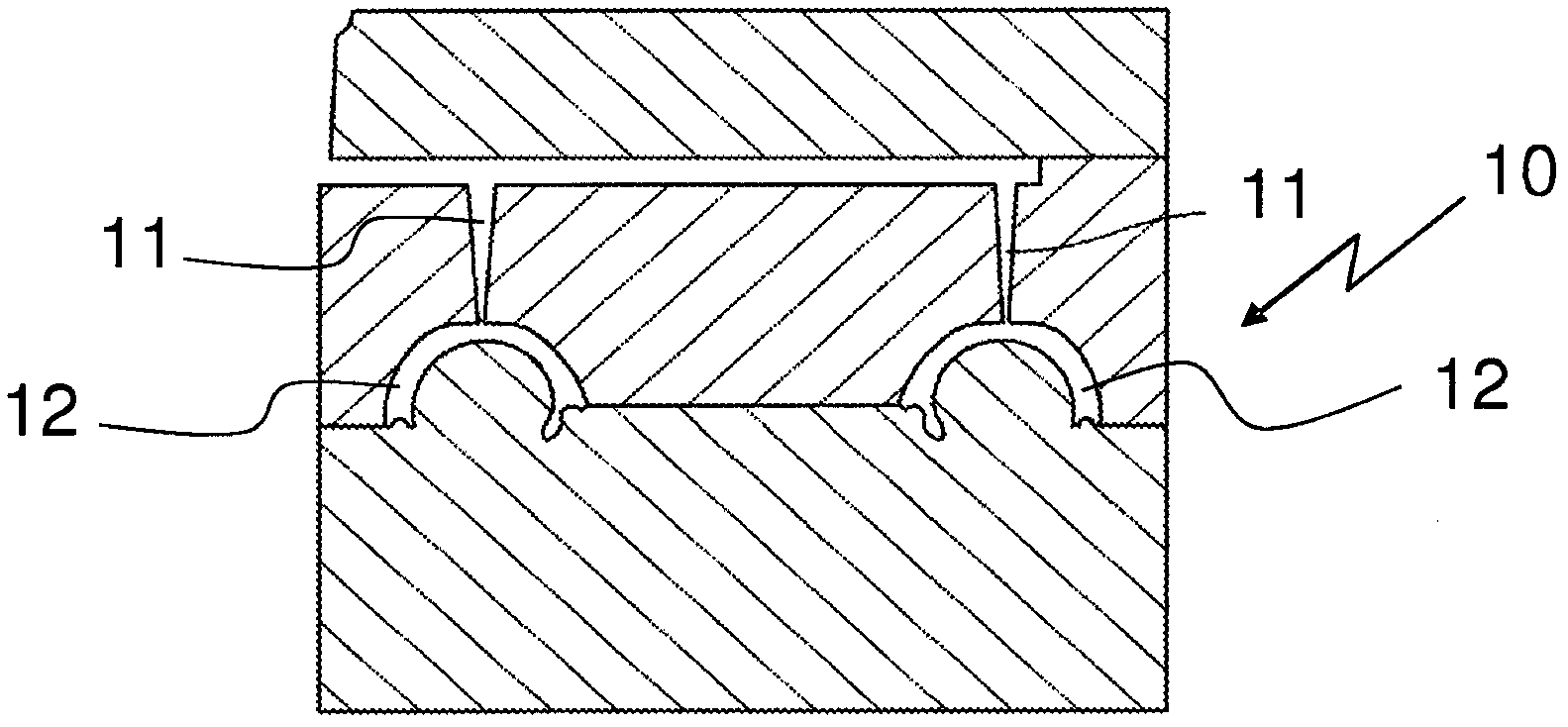

example 1

[0066] A fiber-reinforced thermoplastic and thermally stable PA46 compound, Stanyl Diablo OCD2100, is used as material. A mold slide injection molding dual-cavity mold with cavities for the upper and lower housing parts for the molding of a compressor housing with a diameter of about 10 cm is incorporated in the injection molding member comprising an injection molding extruder group. The temperature settings and injection pressure of the injection molding extruder and the temperature settings of the mold were adjusted to standard molding conditions for the Stanyl material. Inject material into the two cavities, change the position of the cavities so that the two injection molded parts are placed next to each other, forming the shape of the compressor housing while leaving an open channel at the contact area of the two injection molded parts, and placing The material from the second injection is injection molded in this channel. The shell is demoulded while the shell thus f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com