Plastic sealing barrel and preparation method thereof

A technology of plastic sealing and raw materials, applied in the field of plastic products, can solve the problems affecting product quality and corporate image, people's physical injury, product quality decline, etc., and achieve the effect of simple and efficient preparation method, good sealing performance, and good product size setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

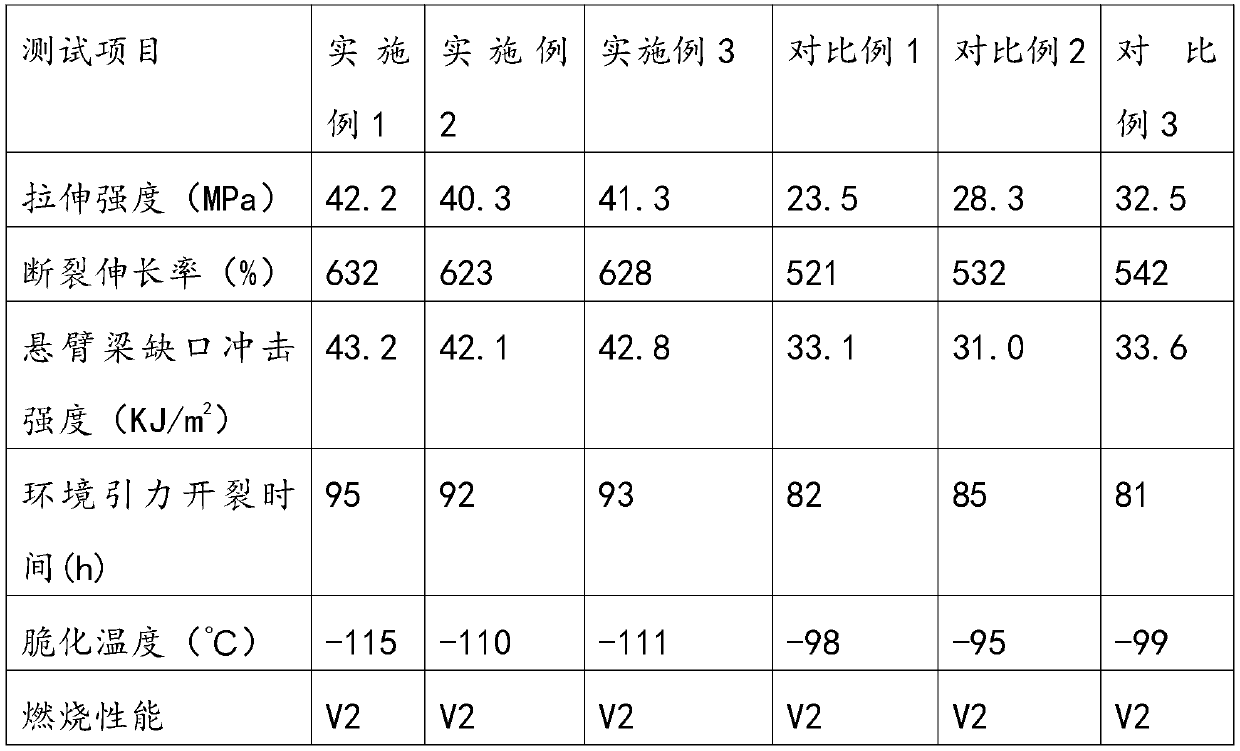

Examples

Embodiment 1

[0033] A preparation method for a plastic airtight bucket, comprising the following steps:

[0034] A. Place 65kg of polypropylene, 25kg of high-density low-pressure polyethylene, 30kg of low-density high-pressure polyethylene and 5kg of calcium hardate in a high-speed mixer according to the proportioning ratio, and stir for 25 minutes at a temperature of 110°C. get the premix;

[0035] B. Add 10kg of calcium carbonate masterbatch, 2kg of distilled glyceryl monostearate, 5kg of phthalate and 2kg of EBFF dispersant to the premix in step A, and stir at a temperature of 140°C 20 minutes, obtain mixture;

[0036] C, the mixture in step B is placed in the twin-screw extruder for melt blending and extruding, and the temperature in each zone is controlled to be 175° C. to obtain mixture particles.

[0037] D. Put the blend particles in the injection molding machine. The barrel temperature of the injection molding machine is 220°C, the nozzle temperature is 230°C, the mold temperatu...

Embodiment 2

[0039] A kind of preparation method of plastic airtight barrel as above, comprises the following steps:

[0040] A. Place 55kg of polypropylene, 15kg of high-density low-pressure polyethylene, 20kg of low-density high-pressure polyethylene and 2kg of calcium hardate in a high-speed mixer according to the proportioning ratio, and stir for 25 minutes at a temperature of 110°C. get the premix;

[0041] B. Add 5kg of calcium carbonate masterbatch, 1kg of distilled glyceryl monostearate, 2kg of phthalate and 1kg of EBFF dispersant to the premix in step A, and stir at a temperature of 140°C 20 minutes to get the mixture;

[0042] C, the mixture in step B is placed in the twin-screw extruder for melt blending and extruding, and the temperature in each zone is controlled to be 175° C. to obtain mixture particles.

[0043] D. Put the blend particles in the injection molding machine. The barrel temperature of the injection molding machine is 190°C, the nozzle temperature is 230°C, the...

Embodiment 3

[0045] A kind of preparation method of plastic airtight barrel as above, comprises the following steps:

[0046] A. Place 59kg of polypropylene, 20kg of high-density low-pressure polyethylene, 25kg of low-density high-pressure polyethylene and 3kg of calcium hardate in a high-speed mixer according to the proportioning ratio, and stir for 25 minutes at a temperature of 110°C. get the premix;

[0047] B. Add 8kg of calcium carbonate masterbatch, 2kg of distilled glyceryl monostearate, 4kg of phthalate and 2kg of EBFF dispersant to the premix in step A, and stir at a temperature of 140°C 20 minutes to get the mixture;

[0048] C, the mixture in step B is placed in the twin-screw extruder for melt blending and extruding, and the temperature in each zone is controlled to be 175° C. to obtain mixture particles.

[0049] D. Put the blend particles in the injection molding machine. The barrel temperature of the injection molding machine is 220°C, the nozzle temperature is 220°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com