Industrial cultivation equipment for insect larvae

A technology for cultivating equipment and larvae, which is applied in animal husbandry and other fields, can solve the problems of labor consumption, large floor area, and many labors, and achieve the effects of saving labor costs, facilitating industrialization, and realizing mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

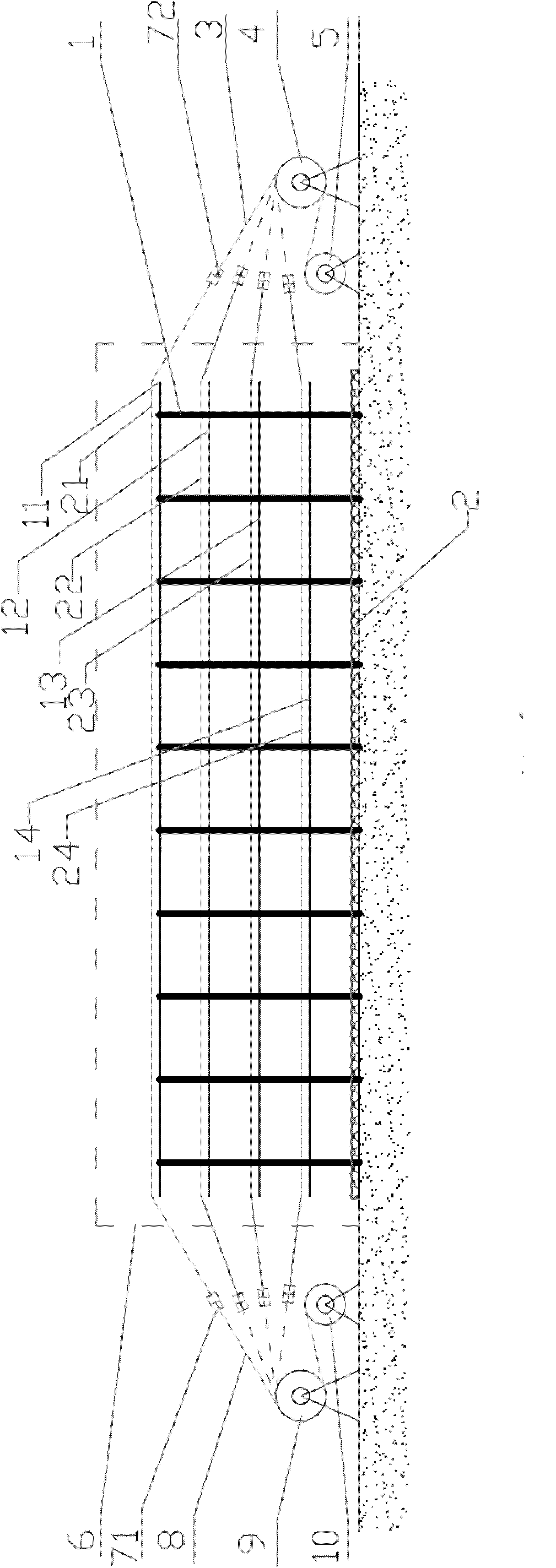

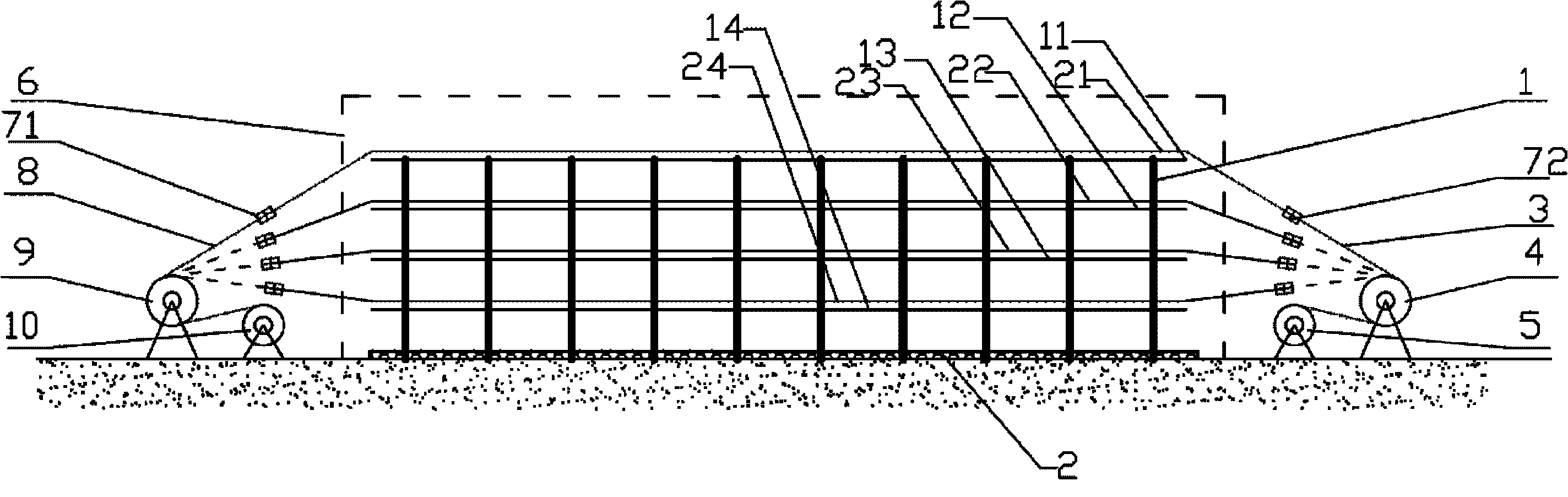

[0017] Such as figure 1 As shown, the insect larvae industrialized cultivation equipment of the present embodiment comprises a three-dimensional support 1 and a connecting film, and four layers of shelves are arranged on the three-dimensional support, namely, a first floor shelf 11, a second floor shelf 12, and a third floor shelf 13. and the fourth layer of frame 14, on these layers of frames respectively lay movable culture membranes, i.e. the first culture membrane 21, the second culture membrane 22, the third culture membrane 23 and the fourth culture membrane 24, along the sides of the culture membrane Spread out the both sides of extension direction to be respectively provided with steering shaft and driving shaft respectively, promptly be provided with left steering shaft 9 and left driving shaft 10 on the left side, be provided with right steering shaft 4 and right driving shaft 5 on the right side, left driving shaft 10 is fixed with a left connecting membrane 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com