Laminated accumulative tobacco charging basket

A tobacco filling and stacking technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of high cost and labor, and achieve the effect of avoiding the collapse and bending of tobacco leaves and improving the utilization rate of curing barn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

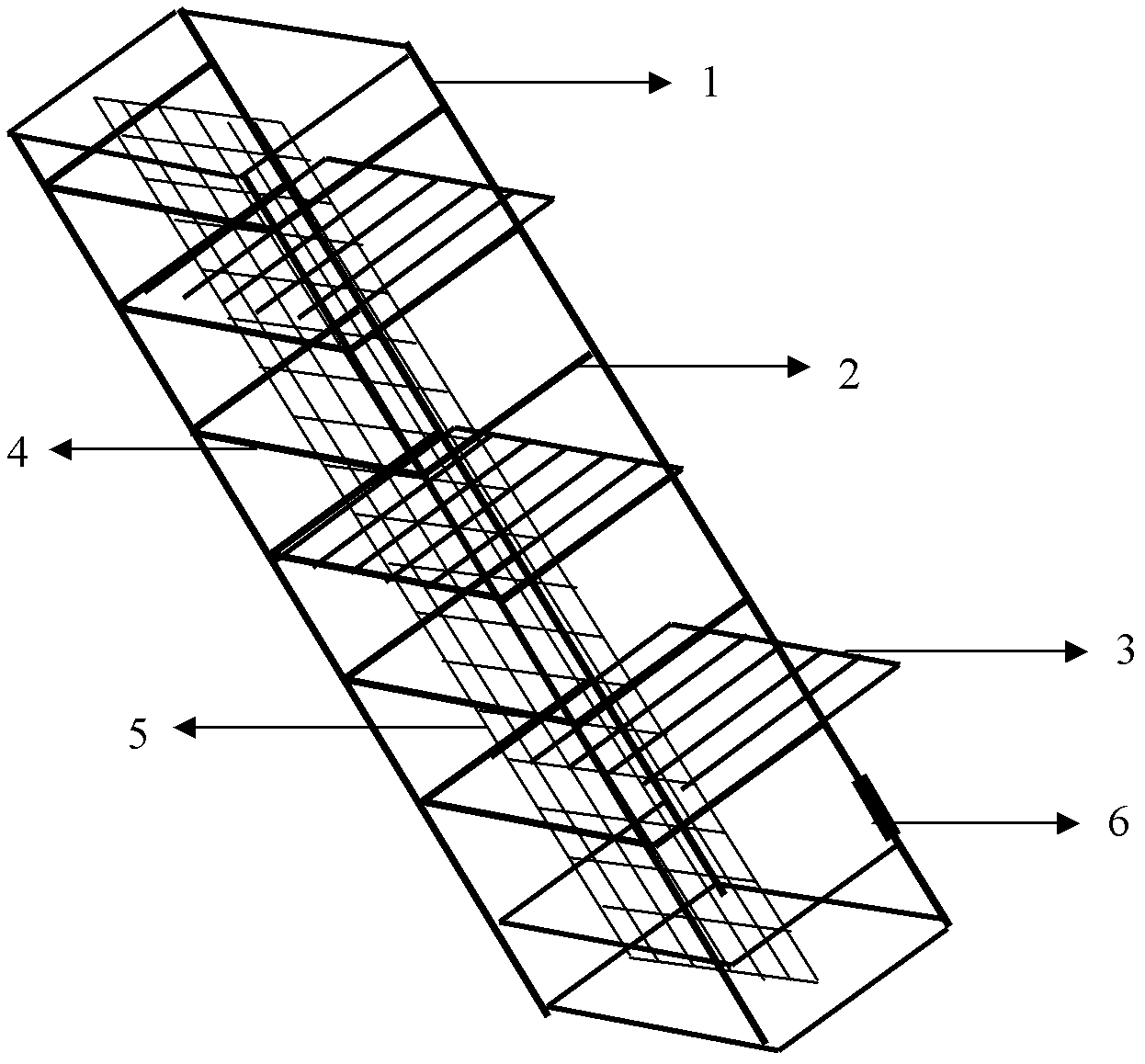

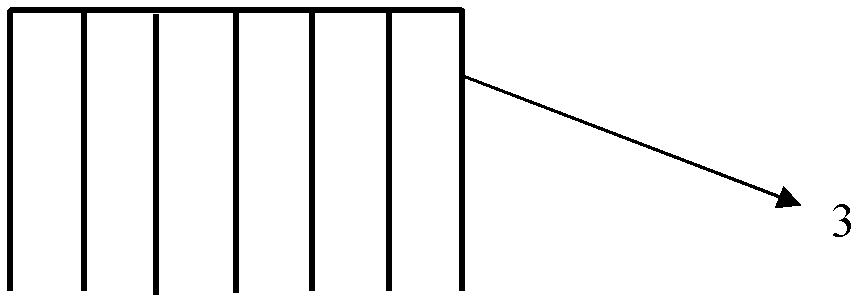

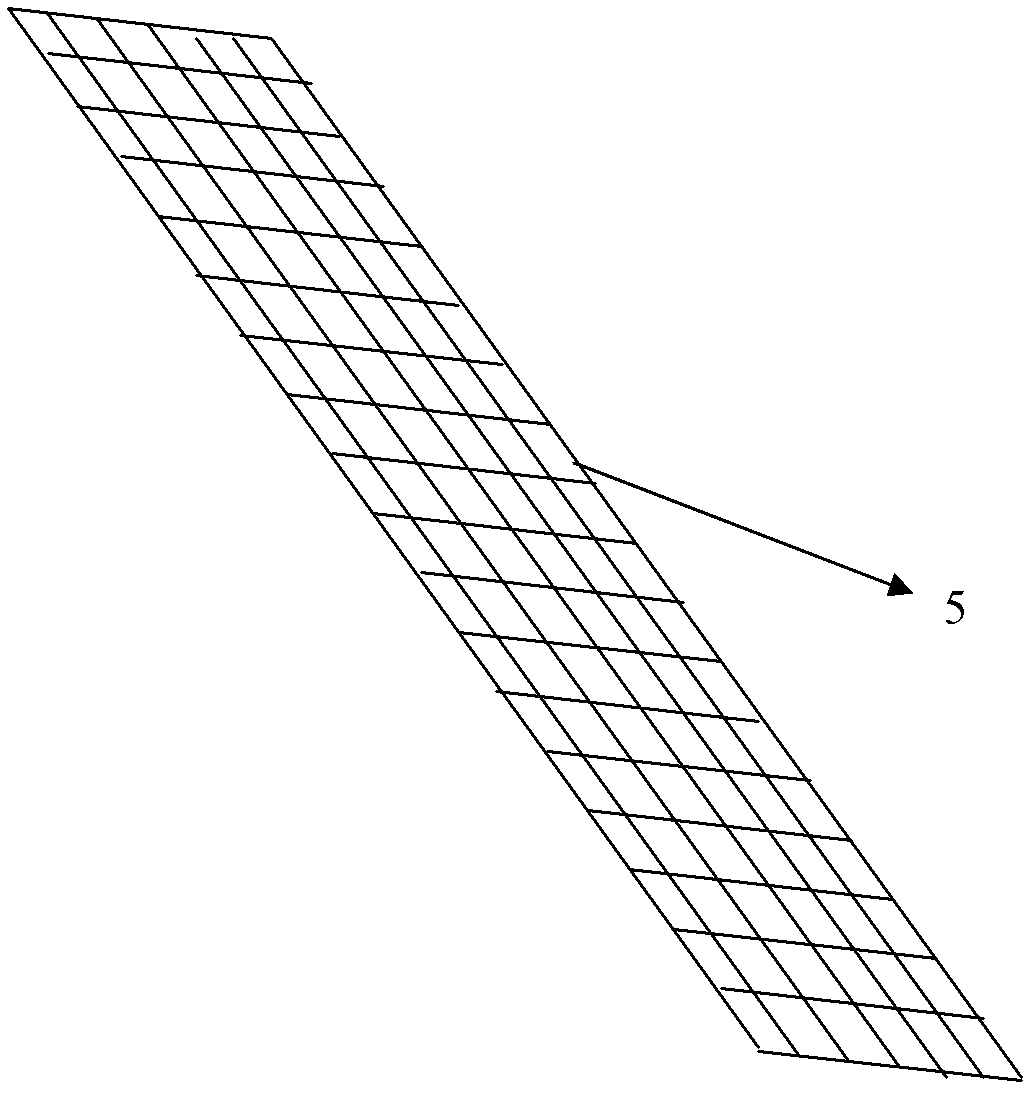

[0013] When the tobacco leaves are harvested, put the mouth of the basket 1 on the open space near the barn, and stack the harvested tobacco leaves in the basket 1. When the tobacco leaves in the basket are filled to a certain amount, the Put into the tobacco leaf limit grid 5 so that the tobacco leaves will not fall during the baking process. Falling, after the tobacco leaf fixed insertion row 3 is inserted into the tobacco leaf fixed insertion row limit groove 2, the tips of the insertion row string needles are respectively placed on the bottom surface retaining strips 4 of the basket to block the tip of the tobacco leaf fixed insertion row 3 from drooping when the basket 1 is erected. Insert the latch 6 to fix the tobacco leaf fixing row 3 and the casing 1 . When loading into the barn, push the flat stacked stacked smoke basket into the corresponding position of the barn and rotate the base 90° towards the direction of the air intake. ○ Stand upright so that the tobacco le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com