Regular disinfection method for continuous unicellular alga culture system and vapor disinfection system thereof

A technology of a culture system and a sterilization method, which is applied in the field of regular sterilization methods and its steam sterilization system, can solve the problems of inability to sterilize methods, sterilization, and large volume of plastic barrels or plastic tanks, so as to save manpower, material resources and power consumption, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

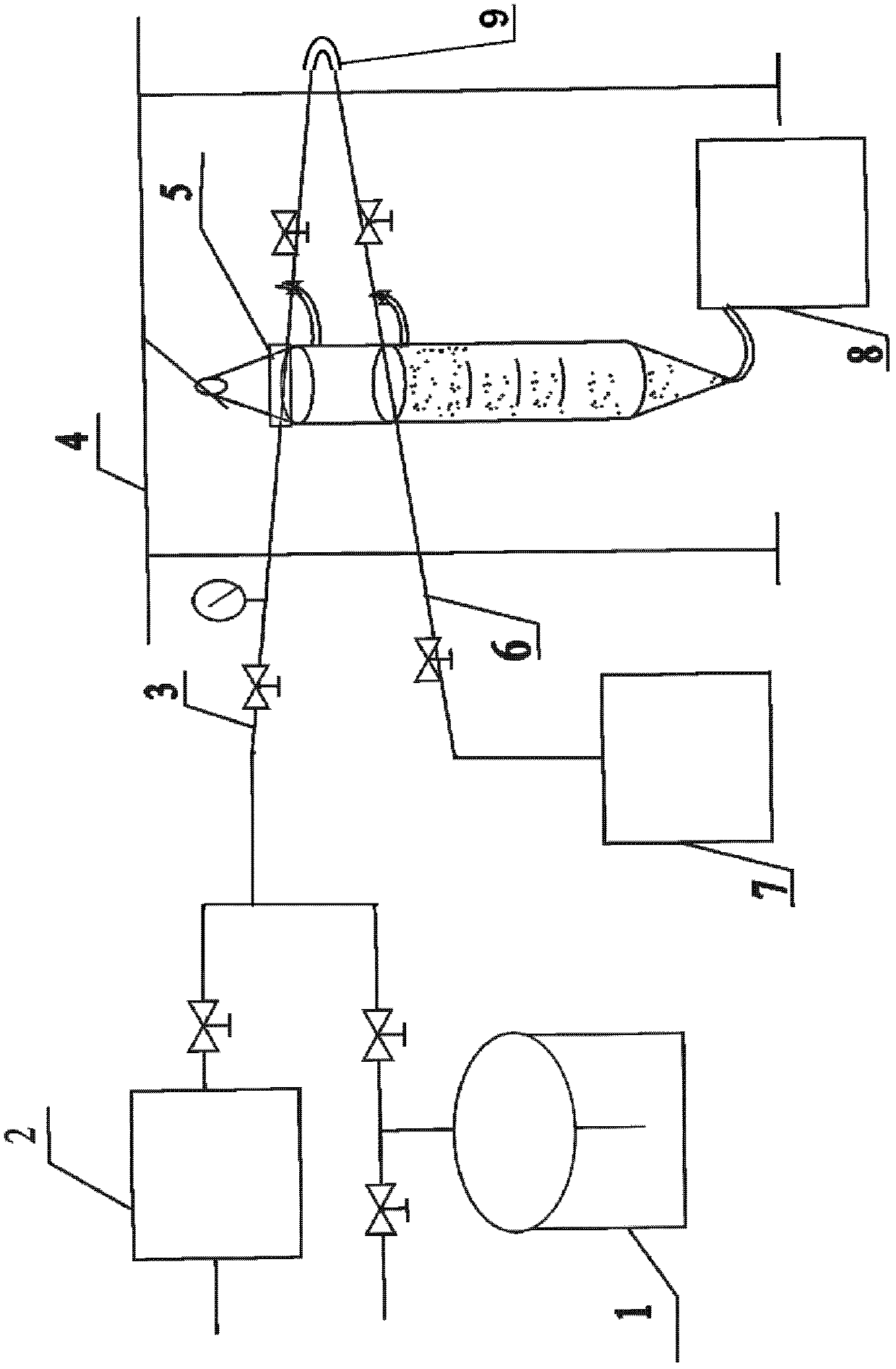

[0045] Such as figure 1 As shown, after each batch of unicellular algae has been cultivated, at first the continuous filling culture solution pipeline 3 in the culture system is communicated with the continuous collection pipeline 6 of the algae liquid with the U-shaped glass tube 9; Filling culture solution pipeline 3 and the branch of algae liquid continuous collection pipeline 6 are closed to form a pipeline to be sterilized;

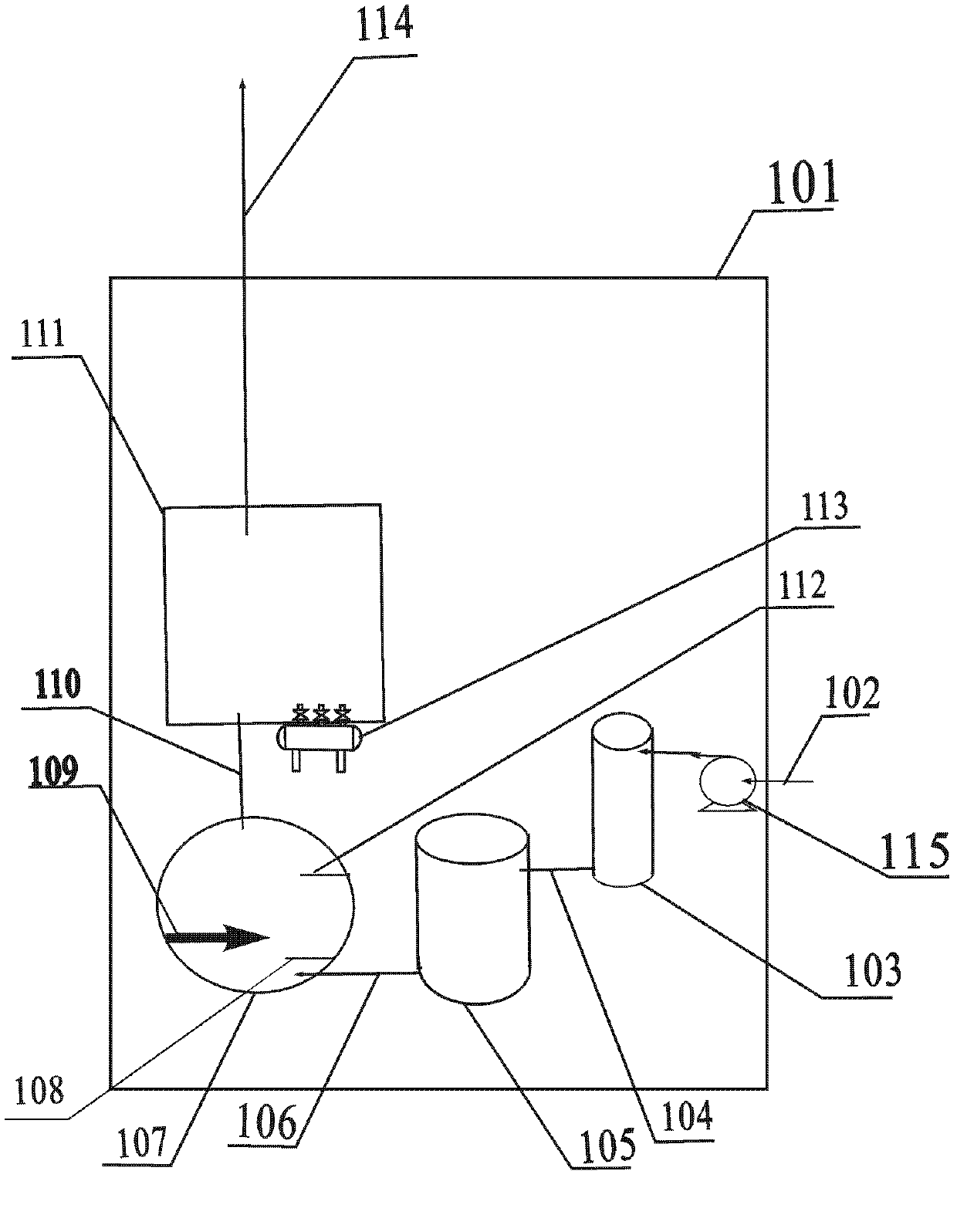

[0046] The steam storage device 111 is connected to the input end of the continuous filling culture solution pipeline 3, so that the steam generated by the steam blowing device 113 is input into the above-mentioned interconnected continuous filling culture solution pipeline 3 and the continuous collection pipeline of algae liquid through the steam delivery pipeline 110 6 for steam sterilization;

[0047] Then use the heated and sterilized water to rinse the connected continuous filling culture solution pipeline 3 and the algae liquid continuous coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com