Punching method for high-density stainless steel mesh plate

A stainless steel mesh and high-density technology, which is applied in the processing field of metal sheet products, can solve the problems of difficult hole diameter accuracy, low yield and high production cost, and solve the problem of sheet metal warping deformation and adjacent hole punching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

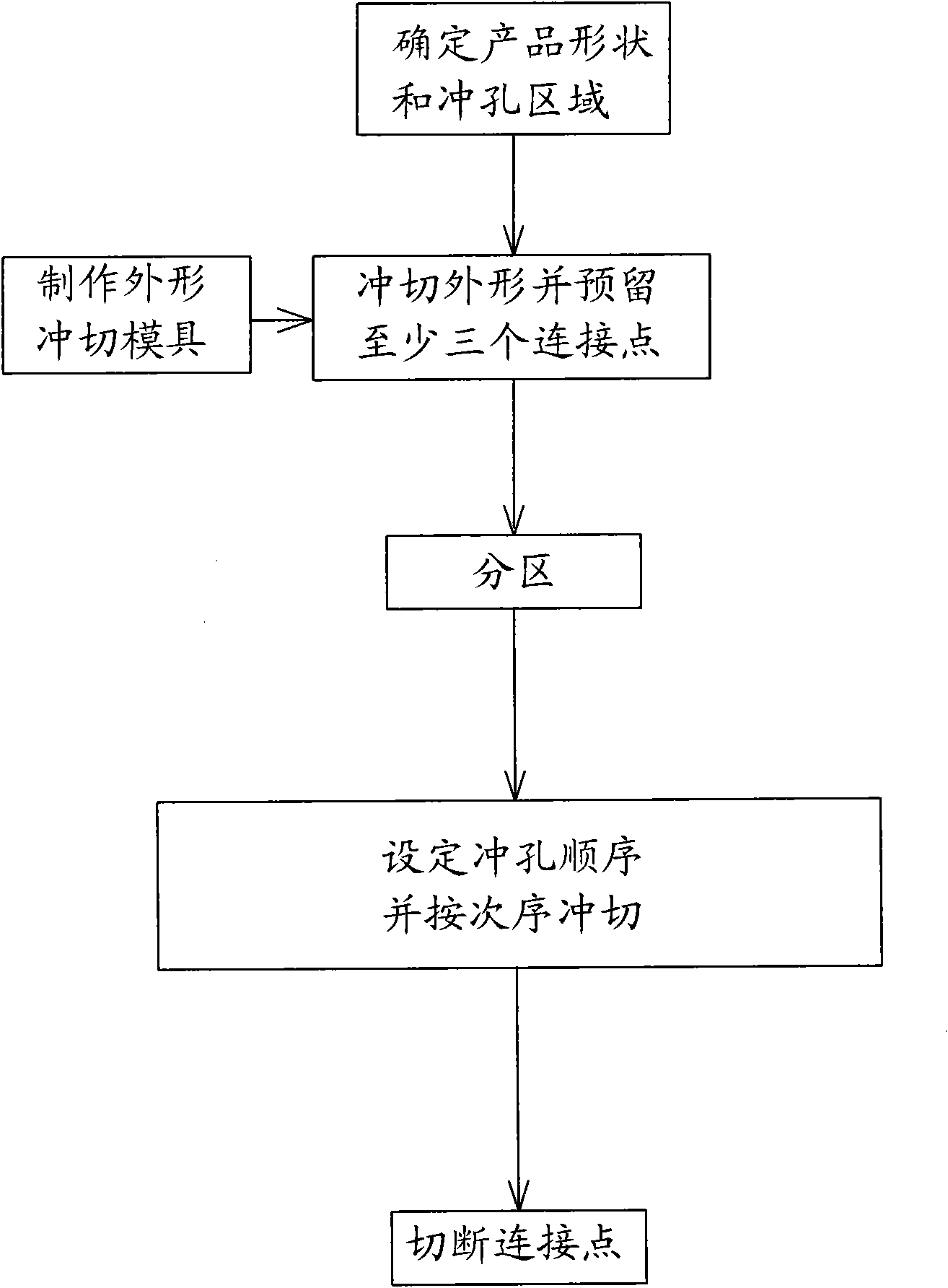

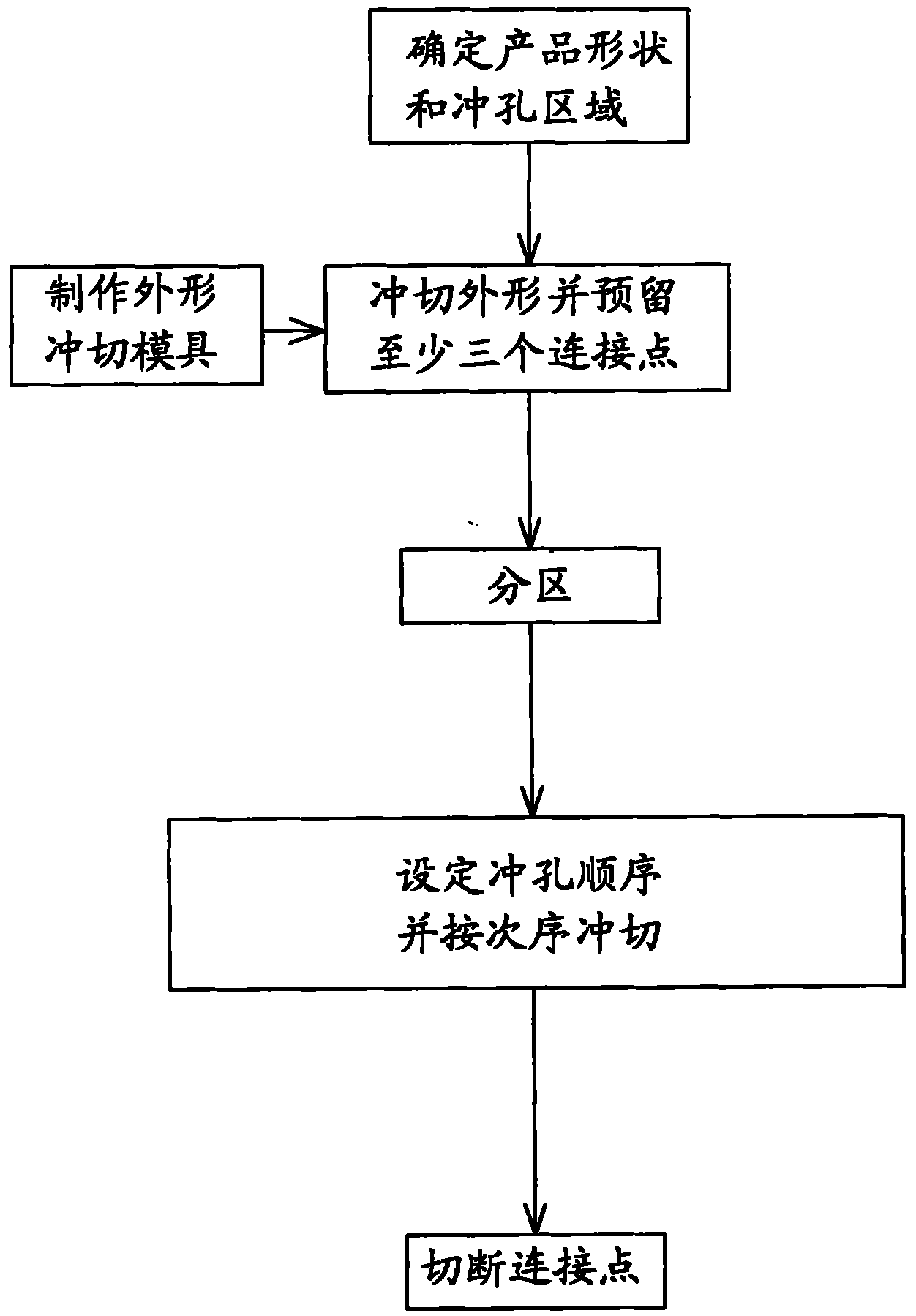

[0041] A punching method for a high-density stainless steel mesh plate, comprising the following steps:

[0042] The first step is to determine the product shape and punching area of the hole according to the design requirements;

[0043] The second step is to set the punching order of the holes, divide the holes to be punched into two parts according to the distance of one hole, and punch the holes in each part in turn;

[0044] The third step is to die-cut the product shape according to the design shape of the product.

[0045] The specific operation process is to determine the shape of the product and the punching area of the hole according to the design requirements, and fix the workpiece on the punching machine, and then divide the holes to be punched into the first part and the second part according to the distance of one hole, and Input the coordinates of the holes of the first part and the second part into the microcomputer of the punching machine respectively. Th...

Embodiment 2

[0047] A punching method for a high-density stainless steel mesh plate, comprising the following steps:

[0048] The first step is to determine the product shape and punching area of the hole according to the design requirements;

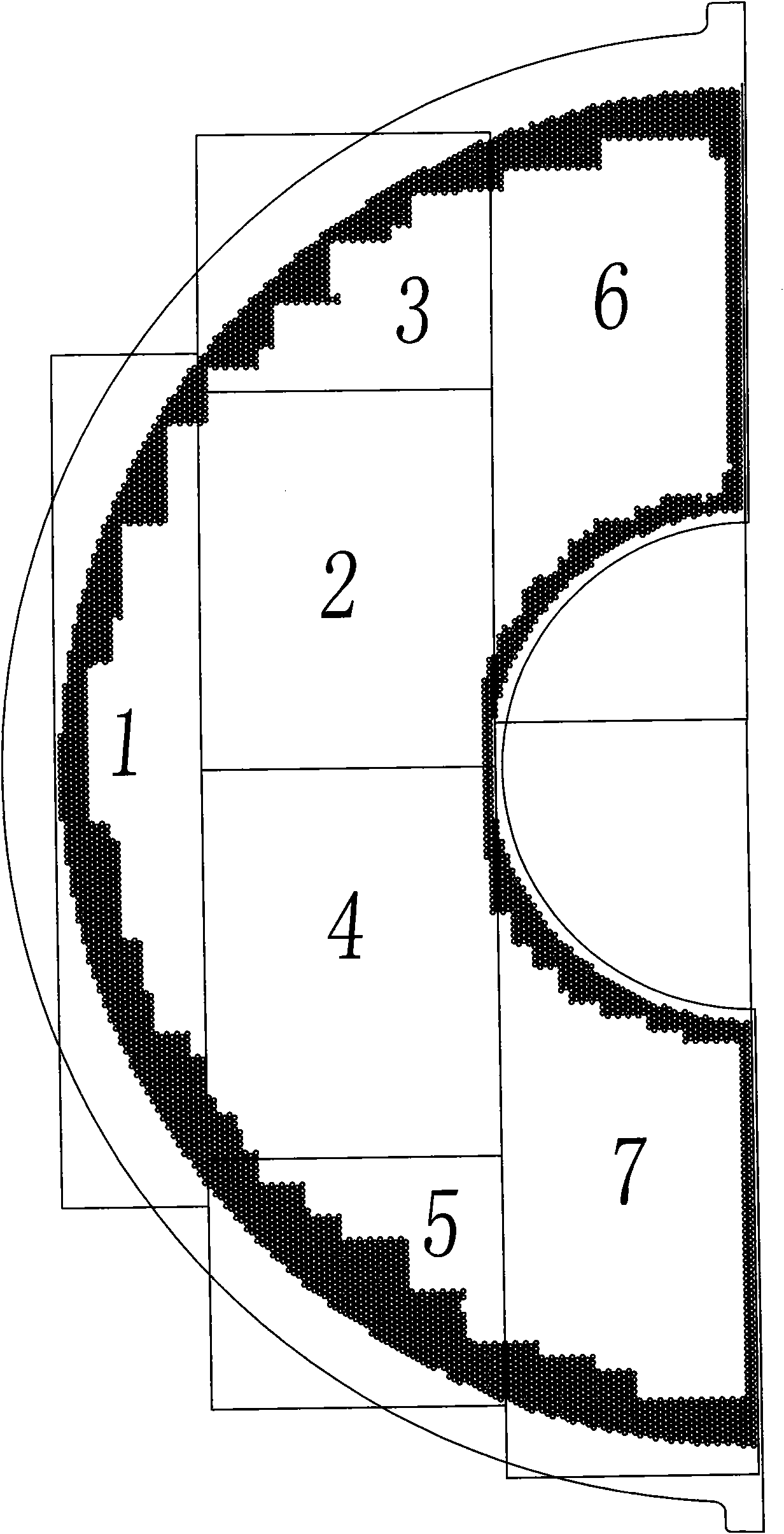

[0049] The second step, partitioning, divides the area to be punched into two areas;

[0050] The third step is to set the hole punching order, divide the holes required to be punched in each area into four parts according to the distance of at least one hole, and punch the holes in each part in turn;

[0051] The fourth step is to die-cut the product shape according to the design shape of the product.

[0052] The specific operation process is to determine the product shape and the punching area of the hole according to the design requirements, and fix the workpiece on the punching machine, then divide the required punching area into the first area and the second area, and then divide the first area and the second area. The holes to be punche...

Embodiment 3

[0054] A punching method for a high-density stainless steel mesh plate, comprising the following steps:

[0055] The first step is to determine the product shape and punching area of the hole according to the design requirements;

[0056] The second step, partitioning, divides the area to be punched into three areas, namely the first area, the second area, and the third area;

[0057] The third step is to set the punching order of the holes, divide the holes required to be punched in each area into three parts according to the distance of at least one, and punch them in turn holes in each part of each area;

[0058] The fourth step is to die-cut the product shape according to the design shape of the product.

[0059] The specific operation process is to determine the product shape and the punching area of the hole according to the design requirements, and fix the workpiece on the punching machine, then divide the required punching area into the first area, the second are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com