Bromine carbon polyurethane steel structure fireproof coating and preparation method thereof

A bromocarbon polyurethane and fire-retardant coating technology, applied in fire-resistant coatings and other directions, can solve the problems of environmental effect migration and failure, inability to achieve flame retardant effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

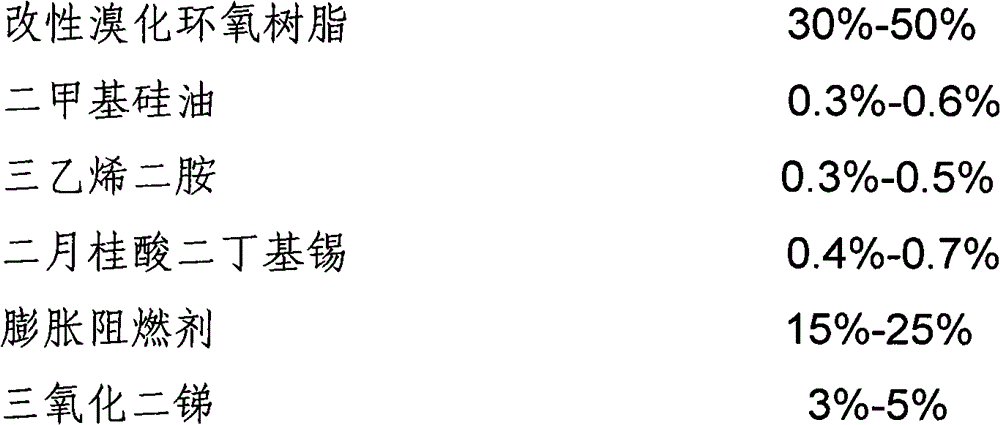

Embodiment 1

[0028] Pre-disperse and grind 35g of modified brominated epoxy resin, 0.17g of dimethyl silicone oil, 0.26g of triethylenediamine, 0.4g of dibutyltin dilaurate, 20g of intumescent flame retardant, and 4.27g of antimony trioxide, as A Components, modified TDI is used as component B, add 25.6g, compound component A and component B, and the fire resistance time of polyurethane fireproof coating is 60min.

Embodiment 2

[0030] Pre-disperse and grind 28g of modified brominated epoxy resin, 0.14g of dimethyl silicone oil, 0.20g of triethylenediamine, 0.34g of dibutyltin dilaurate, 10g of intumescent flame retardant, and 3.41g of antimony trioxide, as A Components, modified TDI is used as component B, add 19.8g, and compound component A and component B to obtain a polyurethane fireproof coating with a fire resistance time of 70 minutes.

Embodiment 3

[0032] Pre-disperse and grind 40g of modified brominated epoxy resin, 0.20g of dimethyl silicone oil, 0.30g of triethylenediamine, 0.49g of dibutyltin dilaurate, 24g of intumescent flame retardant, and 3.0g of antimony trioxide, as A Components, modified TDI is used as component B, add 28.3g, and compound components A and B to obtain a polyurethane fireproof coating with a fire resistance time of 64 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com