Corrosion prevention method for short metal pipe

A technology of core tube and expansion tube, which is applied in the field of metal tube anti-corrosion, can solve the problems of damage to the circumferential welds on both sides, expansion of stainless steel plates, loss of anti-corrosion effect, etc., and achieve the effect of firm combination, tight fit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

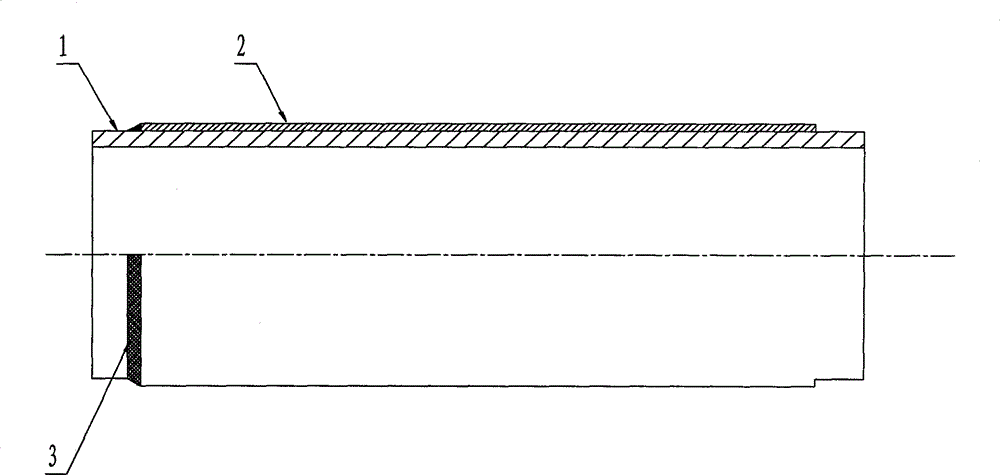

[0010] Refer to attached figure 1 , the method of the present invention is: use a stainless steel plate to make a stainless steel tube 2 whose inner diameter matches the outer diameter of the core tube 1, put the stainless steel tube 2 on the outer wall of the core tube 1, and use the method of mechanical expansion to implement the core tube 1. Expand the tube so that the stainless steel tube 2 and the core tube 1 form a tight fit, and weld one port of the stainless steel tube 2 to the outer wall of the core tube firmly.

[0011] The sleeve core pipe of the buried compensator made by the method of the present invention is used in the buried compensator of the heating pipe network of Baotou City Heating Company. After two heating seasons, no corrosion phenomenon has occurred. However, the sleeve core pipe of the buried compensator in the past needs to be replaced every heating season.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com