Method and device for indirectly measuring leaking amount of fire extinguishing agent in low-pressure carbon dioxide fire extinguishing system

A carbon dioxide, fire extinguishing system technology, applied in measuring devices, by detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc. The problem of low measurement accuracy is to simplify the measurement device and measurement procedure, reduce the error of the test results, and improve the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

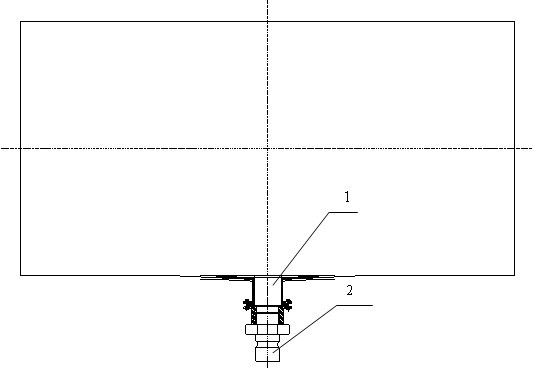

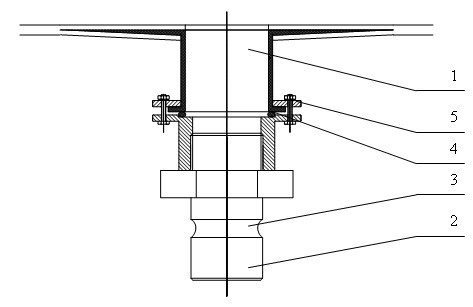

[0012] Below in conjunction with accompanying drawing, the present invention will be further described: with reference to figure 1 , figure 2 , image 3 with Figure 4 The device for indirectly measuring the leakage of fire extinguishing agent in the low-pressure carbon dioxide fire extinguishing system includes a collection container and connecting accessories. The inlet 1 of the collection container is connected with a quick connector male end 2 through a flange 5, and a gasket 4 is added to the connection of the flange 5 to ensure sealing. As a result, the public end 2 of the quick connector is connected to the safety valve of the low-pressure carbon dioxide fire extinguishing system through the connection accessories.

[0013] The connection accessory adopts a high-pressure rubber hose 7 with joints at both ends. One end of the high-pressure rubber hose 7 is a quick connector female end 6, which is directly connected with the quick connector male end 2 on the inlet 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com