Creep-fatigue interaction test device and load loading and unloading method thereof

A technology of interaction and test equipment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of reliability of test results, difficulty in measuring force value changes, etc., and achieve easy realization, stable force value, and control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

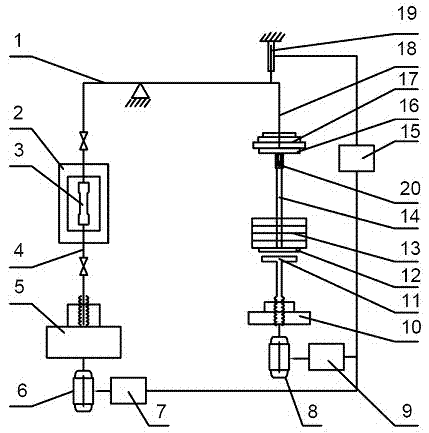

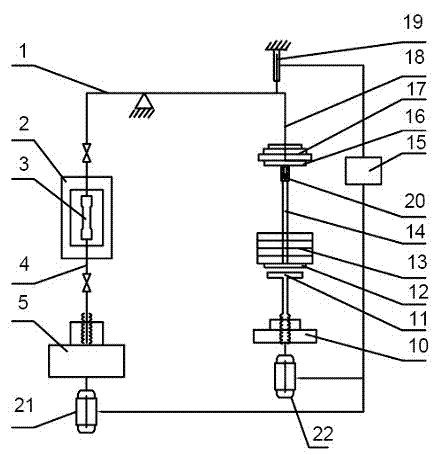

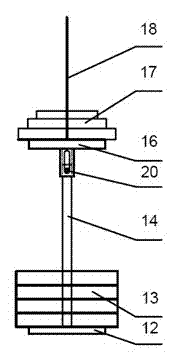

[0022] Such as figure 1 As shown, a kind of creep-fatigue interaction test device provided by the present invention includes a lever 1, one end of the lever 1 is connected with the sample 3 arranged in the high-temperature heating furnace 2 through a pull rod, and the other end is connected with the upper suspension rod 18, and the upper suspension rod 18 is connected with the lower boom 14 through the pin 20, the upper weight tray 16 and the lower weight tray 12 are respectively arranged on the upper boom 18 and the lower boom 14, and the upper weight 17 and the lower weight 13 are respectively arranged on the upper weight On the code tray 16 and the lower weight tray 12, the loading and unloading tray 11 is located below the lower weight tray 12, the loading and unloading tray 11 is located on the loading and unloading transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com