Core elevating mechanism

A lifting mechanism and movement technology, applied in the direction of recording information storage, instruments, etc., can solve the problems of inaccurate coordination, easy wear of the rotating shaft, easy vibration and swing of the rotating shaft, etc., and achieve the effects of saving molds, reducing production costs, and reducing assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

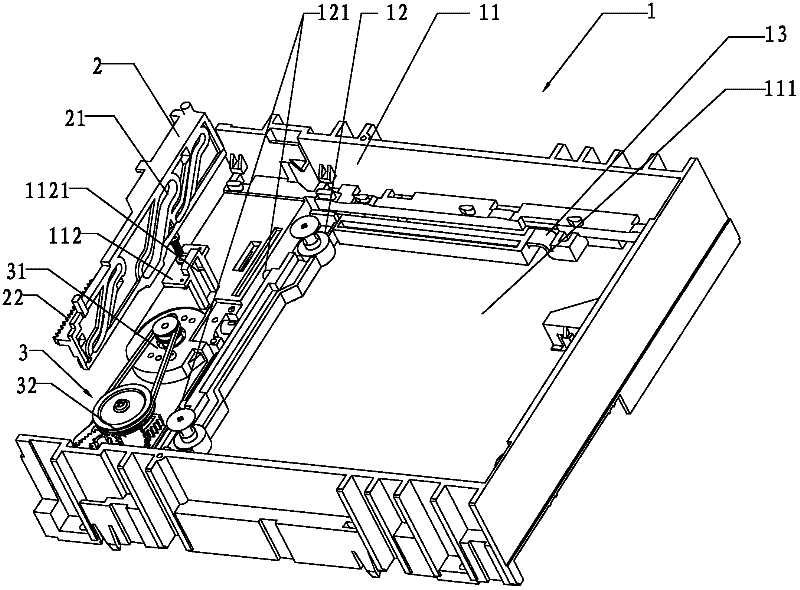

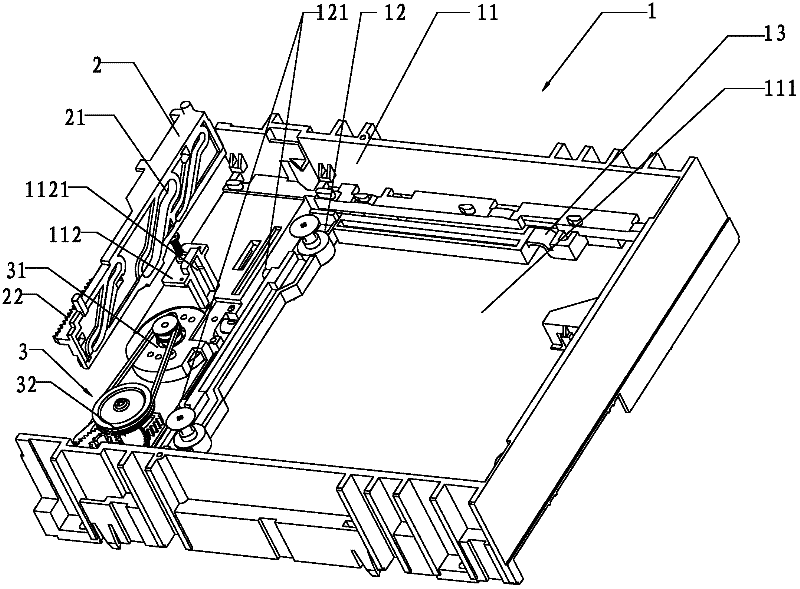

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0020] The present invention as shown provides a core lifting mechanism, which can be applied to all half-height optical drive products, including DVD read-only drives, DVD recording drives, Blu-ray read-only drives, Blu-ray recording drives, household DVD cores, Household Blu-ray movement, etc., in one embodiment, include: a housing 1, including a main frame 11 and a movement support 12, an opening 111 is provided in the main frame 11, and the movement support 12 is arranged in the opening 111, and the movement support 12 is in the shape of a "door", and the two sides of the movement bracket 12 are integrally formed with the main frame 11 through the elastic arm 13;

[0021] Sliding bar 2, the bottom of the sliding bar 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com