Photoelectric composite submarine cable

A technology for optoelectronic composite and submarine cables, applied in the directions of submarine cables, insulated cables, communication cables, etc., can solve the problems of difficult installation and laying, poor tensile strength, poor corrosion resistance, etc. Good tensile performance and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

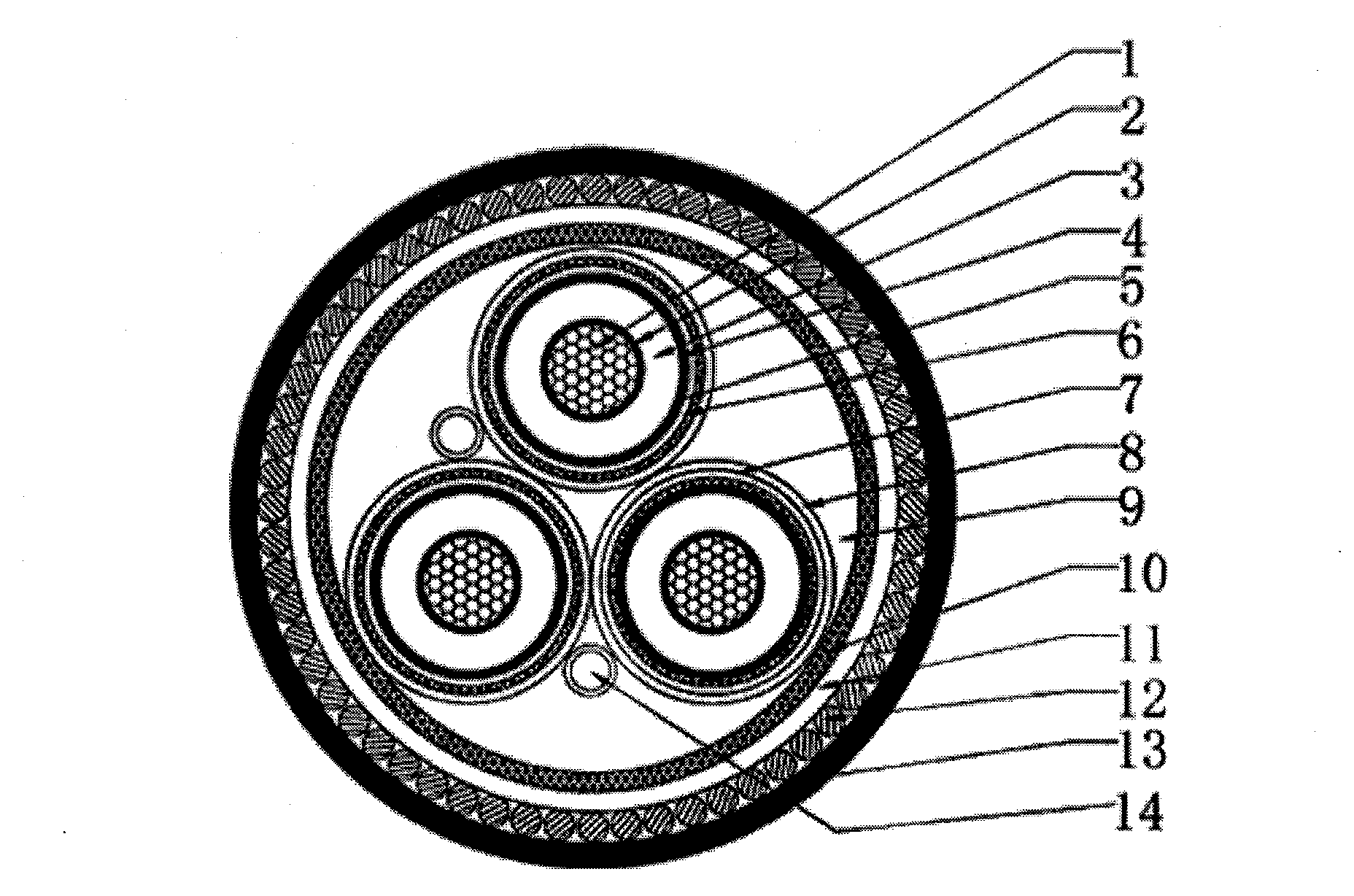

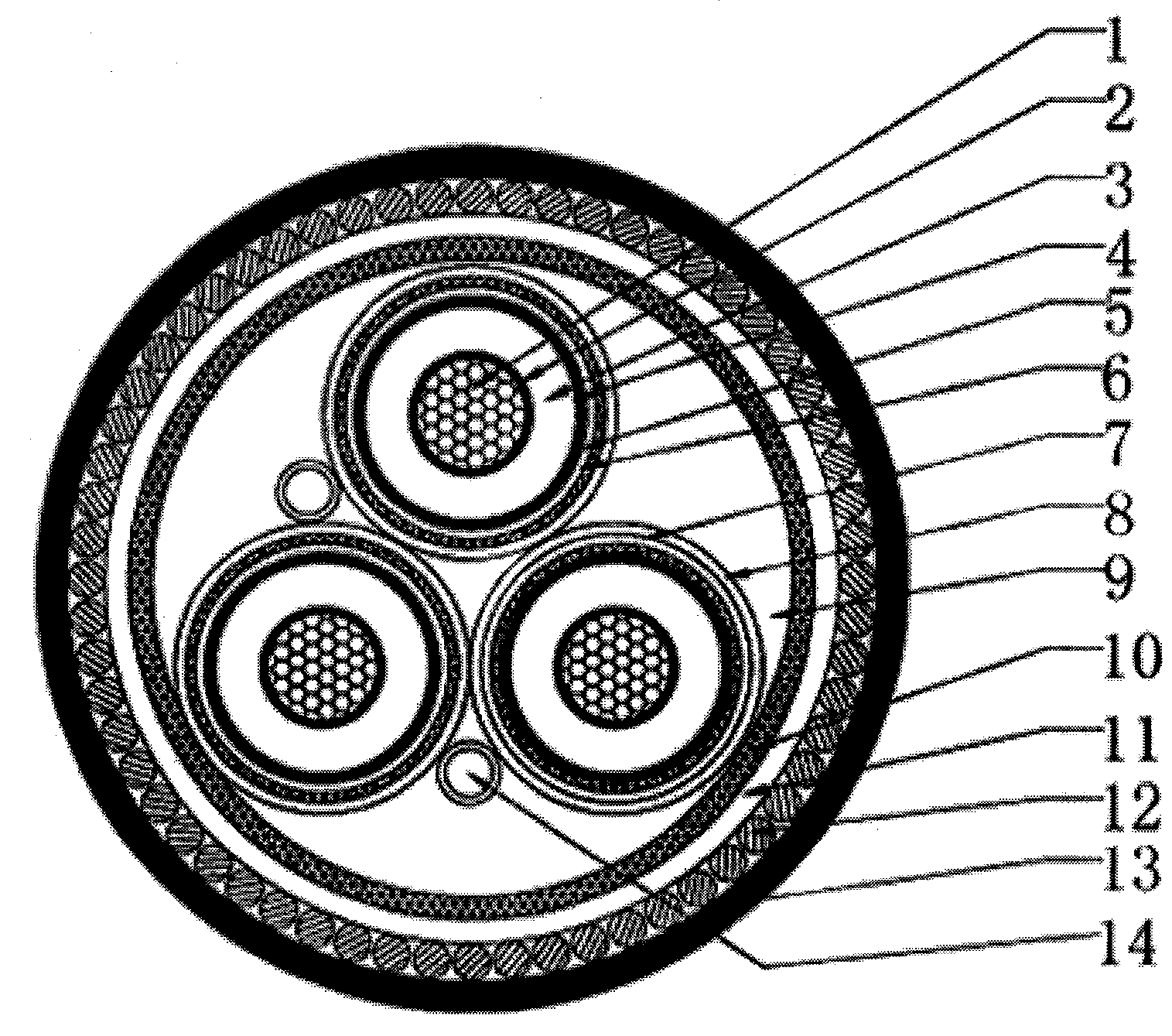

[0031] According to an embodiment of the present invention, a photoelectric composite submarine cable is provided. Such as figure 1 As shown, this embodiment includes an optoelectronic composite assembly arranged in the axial direction, a double-layered axial double-layered positive water layer 10 wrapped around the periphery of the photoelectric composite The armor layer 12 is sleeved on the outer periphery of the inner lining layer 11 , and the outer jacket layer 13 is axially sleeved on the outer periphery of the armor layer 12 .

[0032] Wherein, the above-mentioned armor layer 12 can be galvanized steel wire, and the outer surface of the galvanized steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com