Composite magnetic control sputtering cathode

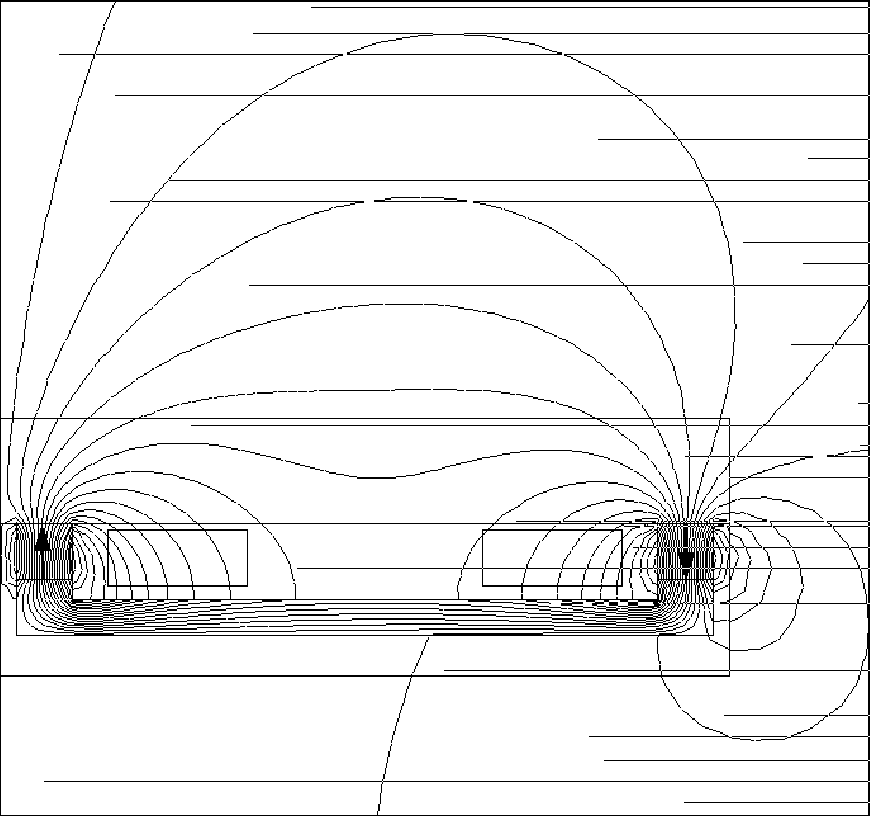

A magnetron sputtering and composite technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problem that the magnetic field cannot be adjusted flexibly, and achieve the effect of improving target utilization and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

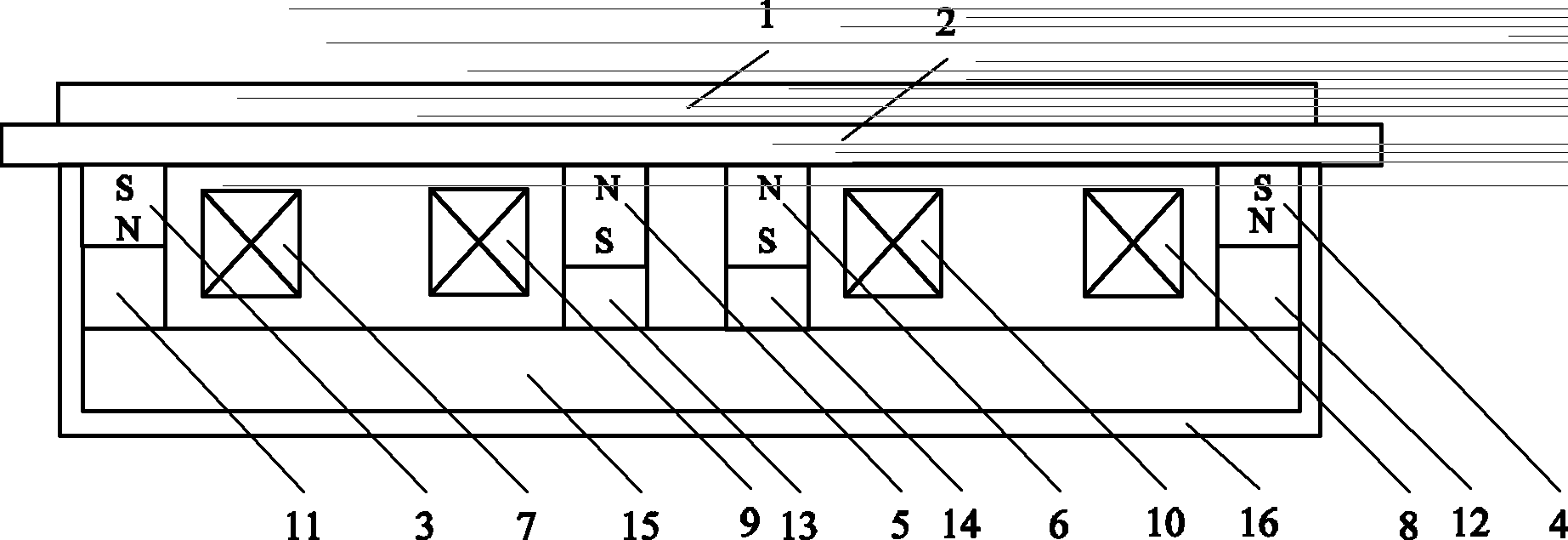

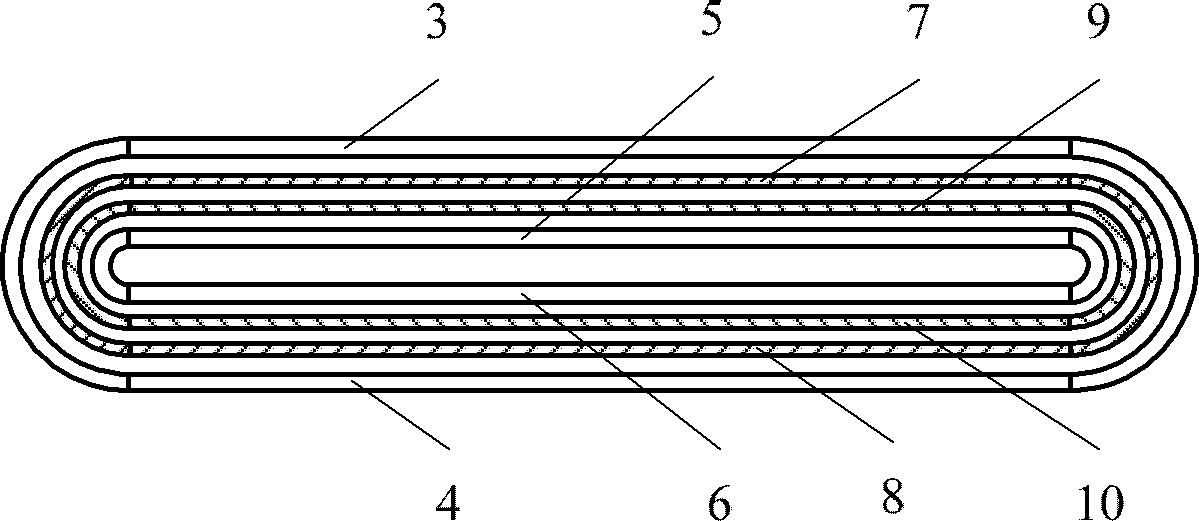

[0023] figure 1 It is a composite magnetron sputtering device of the present invention. Such as figure 1 As shown, the magnetron sputtering cathode is rectangular and flat, composed of a flat target material 1, a water-cooled back plate 2, outer permanent magnets 3 and 4, inner permanent magnets 5 and 6, outer electromagnetic coils 7 and 8, and inner Electromagnetic coils 9 and 10, outer yokes 11 and 12, inner yokes 13 and 14, bottom yoke 15 and frame 16. The water-cooled backplane 2 is a water-cooled frame structure containing cooling water, and a water-cooled pipe is left in the backplane. A plane target 1 is placed on the water-cooled backplane 2, and the plane target 1 and the water-cooled backplane 2 are closely installed together. Below the water-cooled back plate 2 is a magnet frame 16. The frame 16 contains outer permanent magnets 3 and 4, inner permanent magnets 5 and 6, outer electromagnetic coils 7 and 8, inner electromagnetic coils 9 and 10, outer yokes 11 and 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com